Reducer for concrete mixer

A technology of mixing main engine and reducer, which is applied in the direction of mechanical equipment, gear vibration/noise attenuation, transmission parts, etc., and can solve the problem of multi-section reducer, uneven clearance between planetary gear and internal gear tooth side, and reduced processing efficiency and other problems, to reduce the probability of reducer oil leakage, improve stability and reliability, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

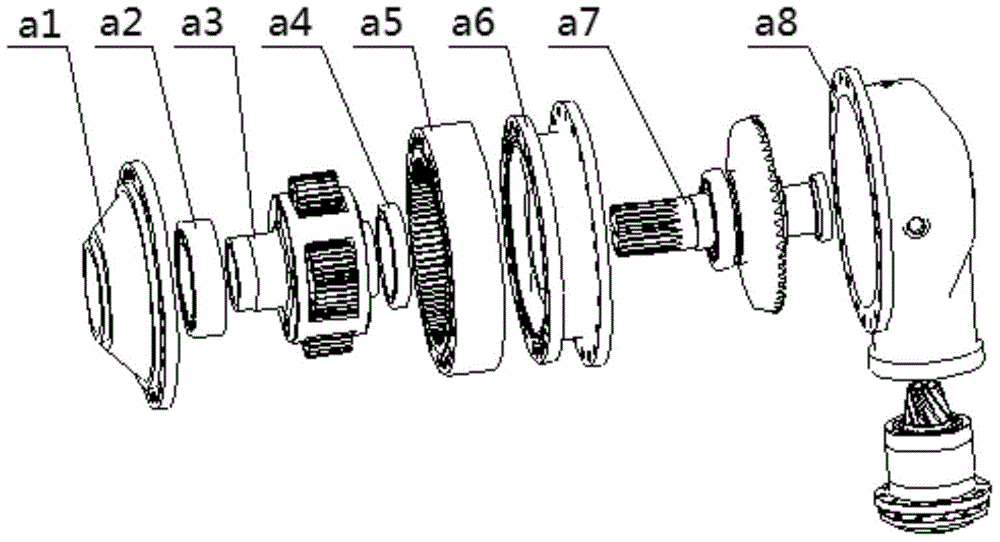

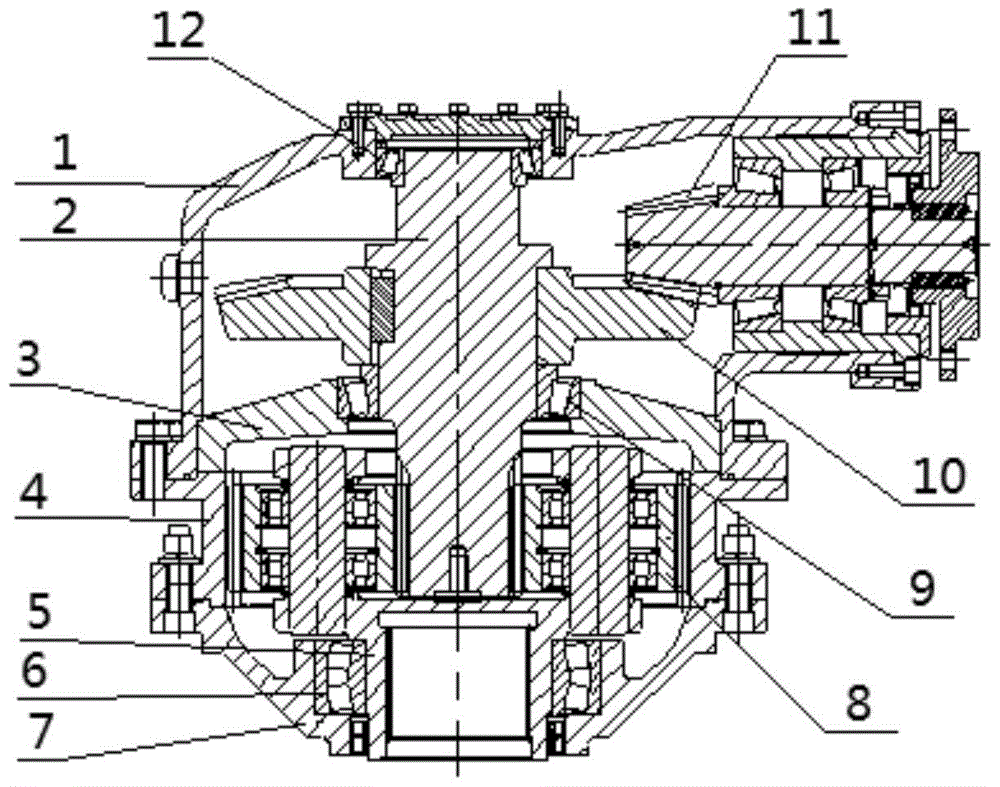

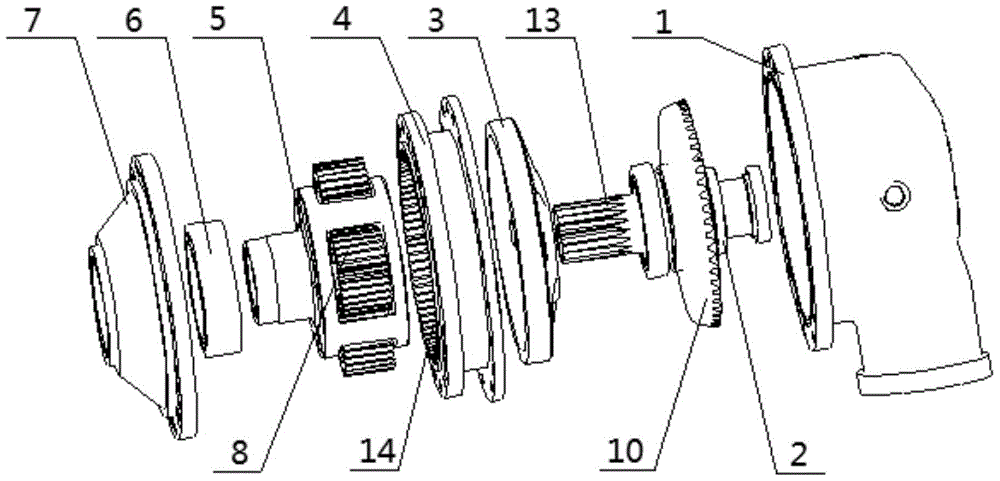

[0018] like figure 2 Shown is a schematic cross-sectional structure diagram of an embodiment of the speed reducer for the concrete mixing main engine of the present invention. combine image 3 , 4 As shown in the exploded diagram of the internal structure, the reducer for the concrete mixing main engine in this embodiment: includes the upper casing 1, the lower casing 7, the planetary carrier assembly 5, the internal gear 4 and the gear shaft 2, and one end of the gear shaft 2 is along the Tooth 13 is provided in the circumferential direction, and extends into the planetary carrier assembly 5, and meshes with each planetary gear 8 in the planetary carrier assembly 5, and each planetary gear 8 of the planetary carrier assembly 5 meshes with the internal gear 4, and the planetary carrier assembly 5 is arranged on Bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com