Water supply control method for ultra-rapid cooling system of hot continuous rolling line

An ultra-fast cooling and control method technology, applied in the field of hot-rolled strip steel rolling, can solve the problems of reducing the ultra-fast cooling capacity, large water flow in the bypass pipeline, and affecting pressure stability, etc., to ensure long-term continuous and stable operation , to meet the needs of water supply, to ensure the effect of flow balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

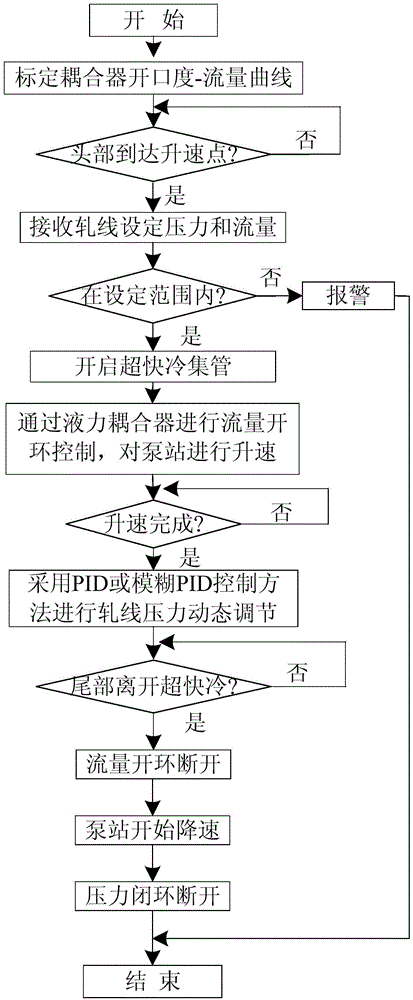

[0039] Such as figure 1 As shown, a water supply control method for an ultra-rapid cooling system of a hot continuous rolling line, comprising the following steps:

[0040] Step 1: Calibrate the hydraulic coupling opening degree-pump station flow curve under a specific pressure. The specific calibration method is as follows:

[0041] Step A: Determine the required calibration set pressure (0.8MPa, 0.85MPa, 0.9MPa and 1.0MPa) and set total flow rate (3000m 3 / h~7500m 3 / h);

[0042] Step B: Calibrate the opening of the hydraulic coupling at 0.8MPa;

[0043] The closed-loop pressure of the rolling line is turned on, and the pressure setting value is set to 0.8MPa. At the same time, the hydraulic coupling of the pump station starts to increase speed from the base speed state, and gradually increases the opening of the hydraulic coupling until the actual flow reaches 3000m 3 / h, stable for 10s, after the flow is in a stable state, record the opening of the hydraulic coupler at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com