A kind of epoxy resin for low gloss powder coating and its preparation method and application

A technology of epoxy resin and powder coating, which is applied in the field of coatings, can solve the problems of high molecular weight structure viscosity, increase cost, and reduce production efficiency, and achieve the effects of low melt viscosity, enhanced mechanical strength, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

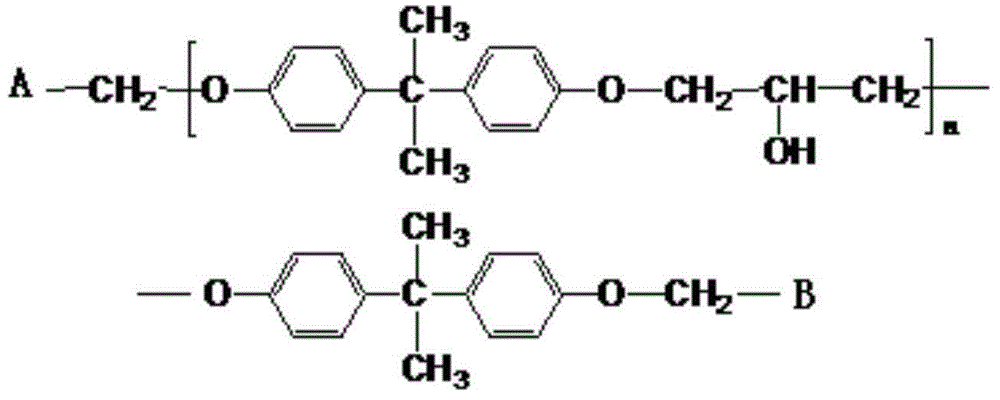

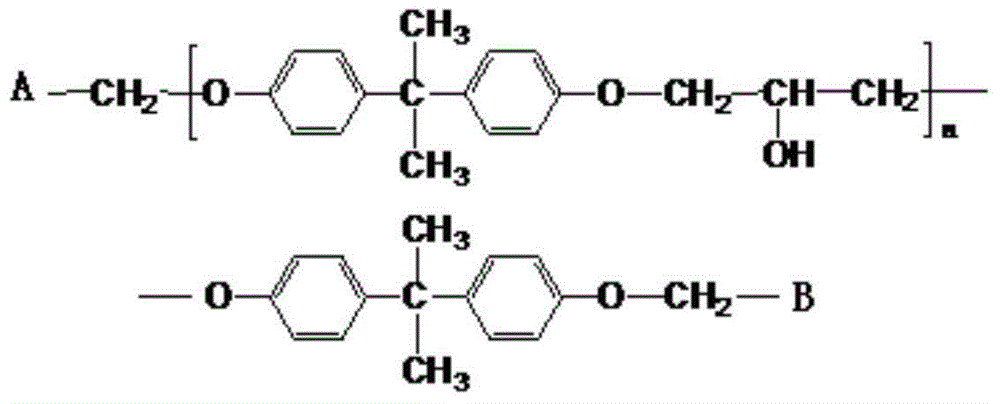

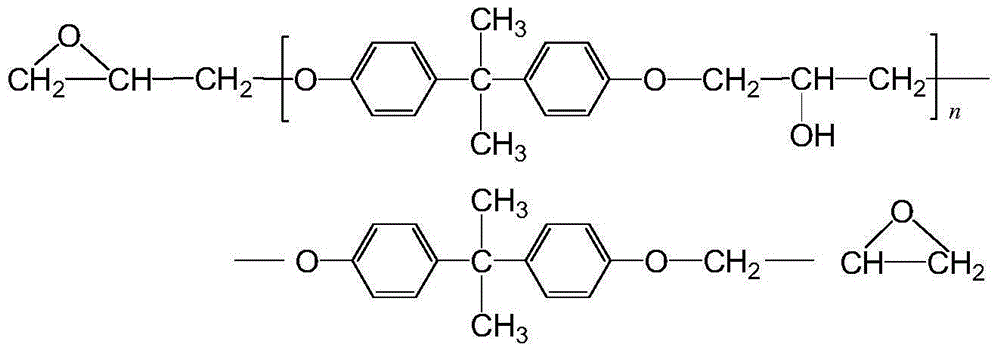

Image

Examples

Embodiment 1

[0048] Add 1mol liquid bisphenol A type epoxy resin 128E, 0.4~0.6mol bisphenol A, 0.04~0.1mol butylphenol into the reaction tank at room temperature, heat to 80~130℃, melt and mix for 10~60min, then add The catalyst is sodium hydroxide, the catalyst amount is 0.1% of the mass of the whole mixture added, and the temperature is continuously raised to 140-180°C for reaction, and the reaction time is 1-2h. Add 0.1-0.2 mol of bisphenol A, react at 140-180° C. for 1-2 hours, and the reaction ends.

Embodiment 2

[0050] Add 1mol liquid bisphenol A epoxy resin 127E, 0.05~0.2mol solid bisphenol A epoxy resin 901, and 0.5~0.8mol bisphenol A into the reaction tank at room temperature, heat to 80~130°C, melt and mix 10-60 minutes, then add the catalyst ethyltriphenylphosphine bromide, the amount of the catalyst is 0.15% of the mass of the whole mixture added, continue to heat up to 140-180°C for reaction, and the reaction time is 1-2 hours. Add 0.04~0.1mol amylphenol, react at 140~180°C, and the reaction time is 1~2h, and the reaction ends.

Embodiment 3

[0052] Add 1mol liquid bisphenol A epoxy resin 128E, 0.05~0.2mol solid bisphenol A epoxy resin 301, 0.2~0.4mol bisphenol A, 0.04~0.1mol heptylphenol into the reaction tank at room temperature, and heat Heat up to 80-130°C, melt and mix for 10-60 minutes, then add catalyst butyltriphenylphosphine bromide, the catalyst amount is 0.05% of the mass of the whole mixture added, heat up to 140-180°C for reaction, and the reaction time is 1-3h . Add 0.1-0.2 mol of bisphenol A, react at 140-180° C. for 1-2 hours, and the reaction ends.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com