Impurity removal method of electrolytic manganese dioxide

A technology of electrolytic manganese dioxide and manganese dioxide, applied in the direction of manganese oxide/manganese hydroxide, electrolytic components, electrolytic process, etc., can solve the problems of large water consumption, long soaking time, poor washing effect of impurities, etc., and achieve Good effect, short processing time, and the effect of improving discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

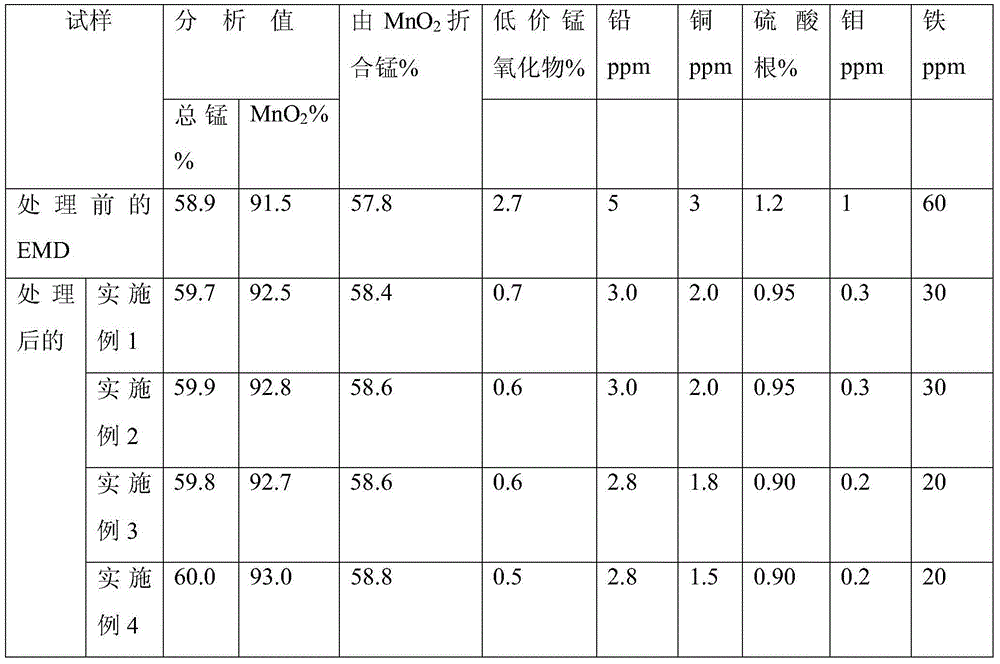

Embodiment 1

[0019] A method for removing impurities from electrolytic manganese dioxide, which is carried out according to the following steps: crush the manganese dioxide peeled off from the anode to 200 mesh, add dilute sulfuric acid and nitric acid with 2.0% of the mass of manganese dioxide, mix well, dilute sulfuric acid and nitric acid The mass ratio is 1:0.3, the concentration of dilute sulfuric acid is 0.05mol / L, and the mass percentage of nitric acid is 4%; after mixing evenly, place the manganese dioxide at 250°C for 40min and then burn it at 5°C / min. Speed is cooled to 80 ℃, filters after cooling, and the manganese dioxide that filter stays pickles with dilute sulfuric acid, after pickling, mix with a small amount of water (in the present invention, there is no limitation for the proportioning of manganese dioxide and water, as long as the Add the water in the container to cover the electrolytic manganese dioxide), heat to 70°C with microwave, microwave power is 300W, and use 3...

Embodiment 2

[0021] A method for removing impurities from electrolytic manganese dioxide, which is carried out according to the following steps: crush the manganese dioxide peeled off from the anode to 300 mesh, add dilute sulfuric acid and nitric acid with 1.5% of the mass of manganese dioxide, mix evenly, dilute sulfuric acid and nitric acid The mass ratio is 2:0.3, the concentration of dilute sulfuric acid is 0.08mol / L, and the mass percentage of nitric acid is 3%; after mixing evenly, place manganese dioxide at 240°C for 45min, and then burn it at 7°C / min. Speed is cooled to 75 ℃, filters after cooling, and the manganese dioxide that filter stays pickles with dilute sulfuric acid, after pickling, mixes with a small amount of water (in the present invention, there is no limit for the proportioning of manganese dioxide and water, as long as the Add the water in the container to cover the electrolytic manganese dioxide), heat to 60°C with microwave, microwave power is 250W, and use 35KHz...

Embodiment 3

[0023] A method for removing impurities from electrolytic manganese dioxide, which is carried out according to the following steps: crush the manganese dioxide peeled off from the anode to 400 mesh, add dilute sulfuric acid and nitric acid with 1.0% of the mass of manganese dioxide, mix well, dilute sulfuric acid and nitric acid The mass ratio is 1.5:0.3, the concentration of dilute sulfuric acid is 0.10mol / L, and the mass percentage of nitric acid is 2.5%; after mixing evenly, place the manganese dioxide at 230°C for 50 minutes, and then burn it at 8°C / min. Speed is cooled to 70 ℃, filters after cooling, and the manganese dioxide that filter stays pickles with dilute sulfuric acid, after pickling, mix with a small amount of water (in the present invention, there is no limitation for the proportioning of manganese dioxide and water, as long as the Add the water in the container to cover the electrolytic manganese dioxide), heat to 50°C with microwave, microwave power is 200W,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com