Cylinder type membrane assembly prepared from multi-inner-hole membrane

A technology of endoporous membranes and components, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve problems such as increasing aeration energy consumption, increasing aeration space area requirements, and complexity, etc. Achieve stable membrane water flux, economical and convenient installation and maintenance, and reduce membrane damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

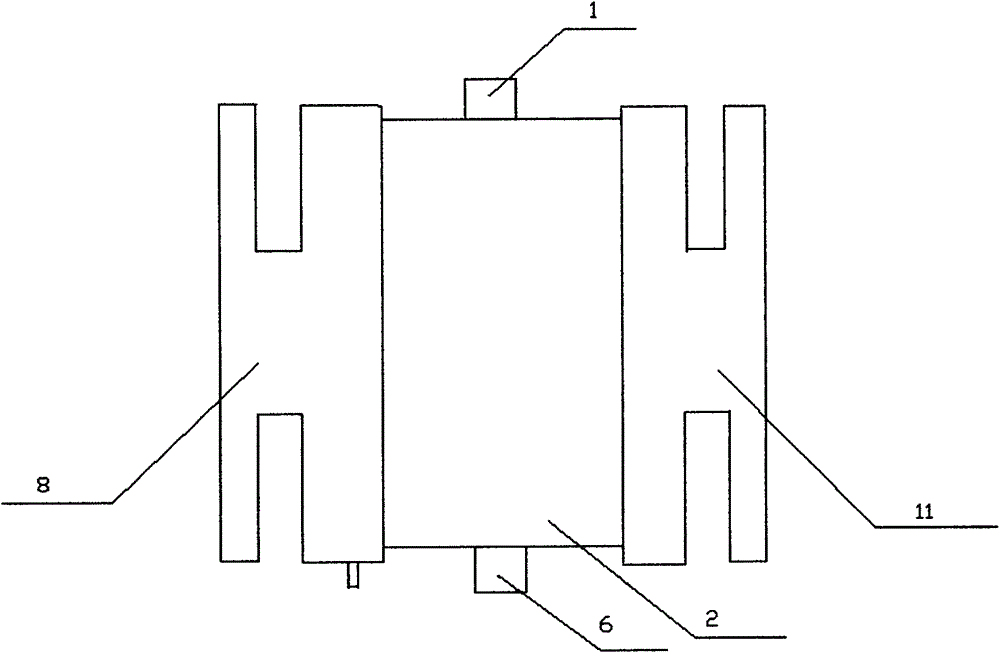

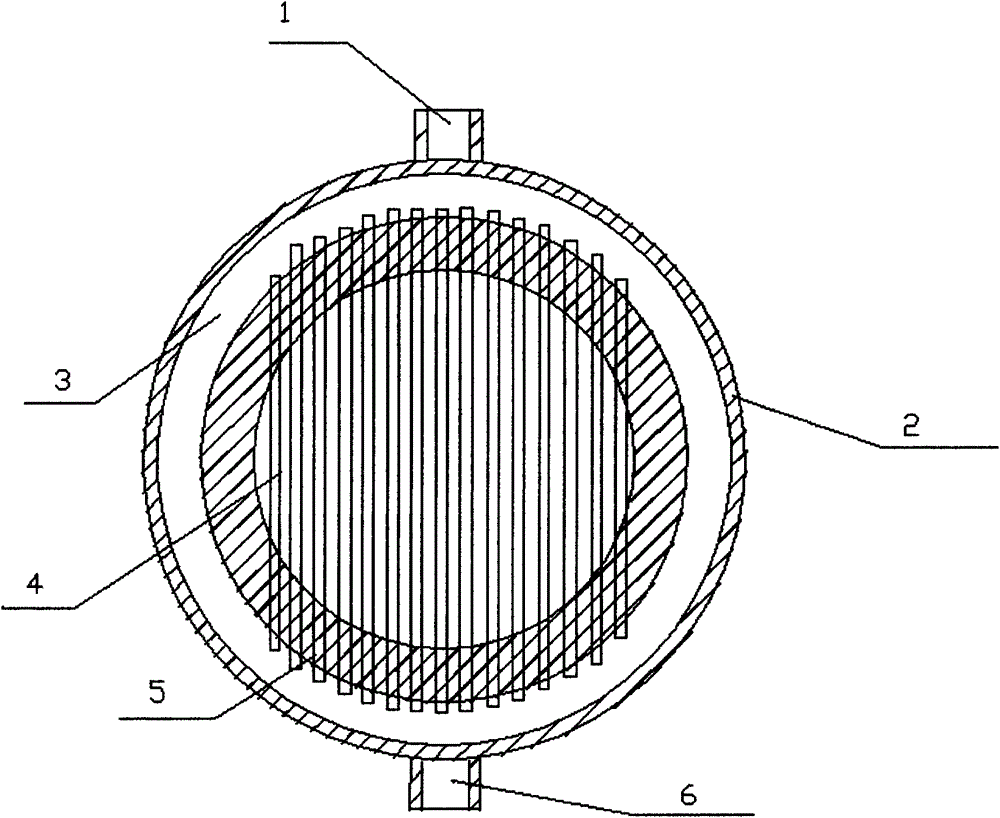

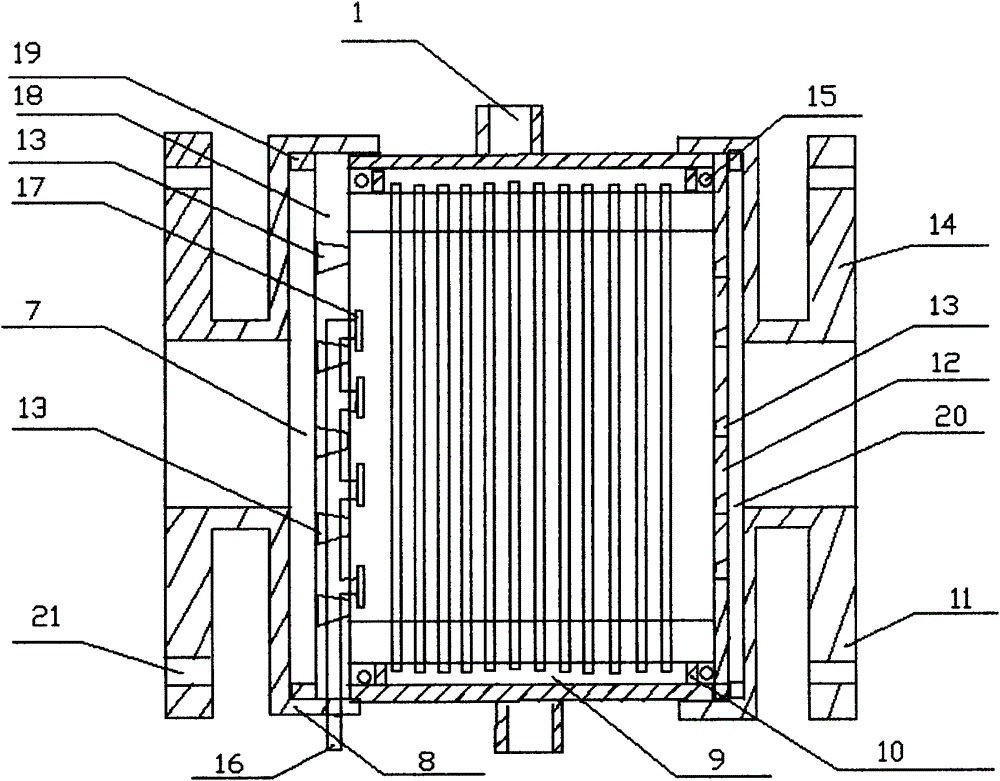

[0037] Embodiment one: figure 1 is a schematic front view of a cylindrical hollow fiber membrane module according to an embodiment of the present invention, figure 2 yes figure 1 The cross-sectional schematic diagram of the cylindrical hollow fiber membrane module shown, image 3 yes figure 1 A schematic longitudinal section of the cylindrical hollow fiber membrane module shown. Such as image 3 As shown, the shell diameter of the hollow fiber membrane module is 5.25 inches, the length of the membrane module is 8 inches, the diameter of the pipe where the raw water enters the flange end cover is 3 inches, and the membrane area is 1m 2 , Bolt center hole diameter of flange outer ring is 6 inches, flange bolt hole diameter is 0.75 inches, 4 bolts. The material of the membrane wire is PVDF, with three inner holes, the outer diameter of the membrane wire is 3mm, and the inner hole is 0.65mm, such as Figure 5 As shown, the pore size of the membrane filter is 0.2um, and the ...

Embodiment 2

[0038] Embodiment two: Figure 4 is a schematic longitudinal sectional view of a cylindrical hollow fiber membrane module according to another embodiment of the present invention. Such as Figure 4 As shown, the shell diameter of the hollow fiber membrane module is 13.25 inches, the length of the membrane module is 24 inches, the diameter of the pipe where the raw water enters the flange end cover is 10 inches, and the membrane area is 4m 2 , The diameter of the outer circle of the flange of the bolt center hole is 14.25 inches, the diameter of the bolt hole of the flange is 1 inch, and 12 bolts. The material of the membrane is PES, with three inner holes, the outer diameter of the membrane is 1.8mm, and the inner hole is 0.45mm, such as Figure 5 As shown, the pore size of the membrane filter is 0.05um, and the membrane support layer is shown in Figure 6 right picture. The diversion aeration device 18 is an aeration head and an aeration pipe between the diversion hole pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com