Rotating magnetic field-membrane bioreactor joint ship oily sewage treatment method

A technology of membrane bioreactor and rotating magnetic field, which is applied in biological water/sewage treatment, water/sewage treatment, sustainable biological treatment, etc. It can solve the problems of prolonged operation time of reactors, blockage of membrane pores, and decreased degradation efficiency of organic matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] COD in treated oily wastewater Cr The content is about 500mg / L, and the oil content is about 50mg / L.

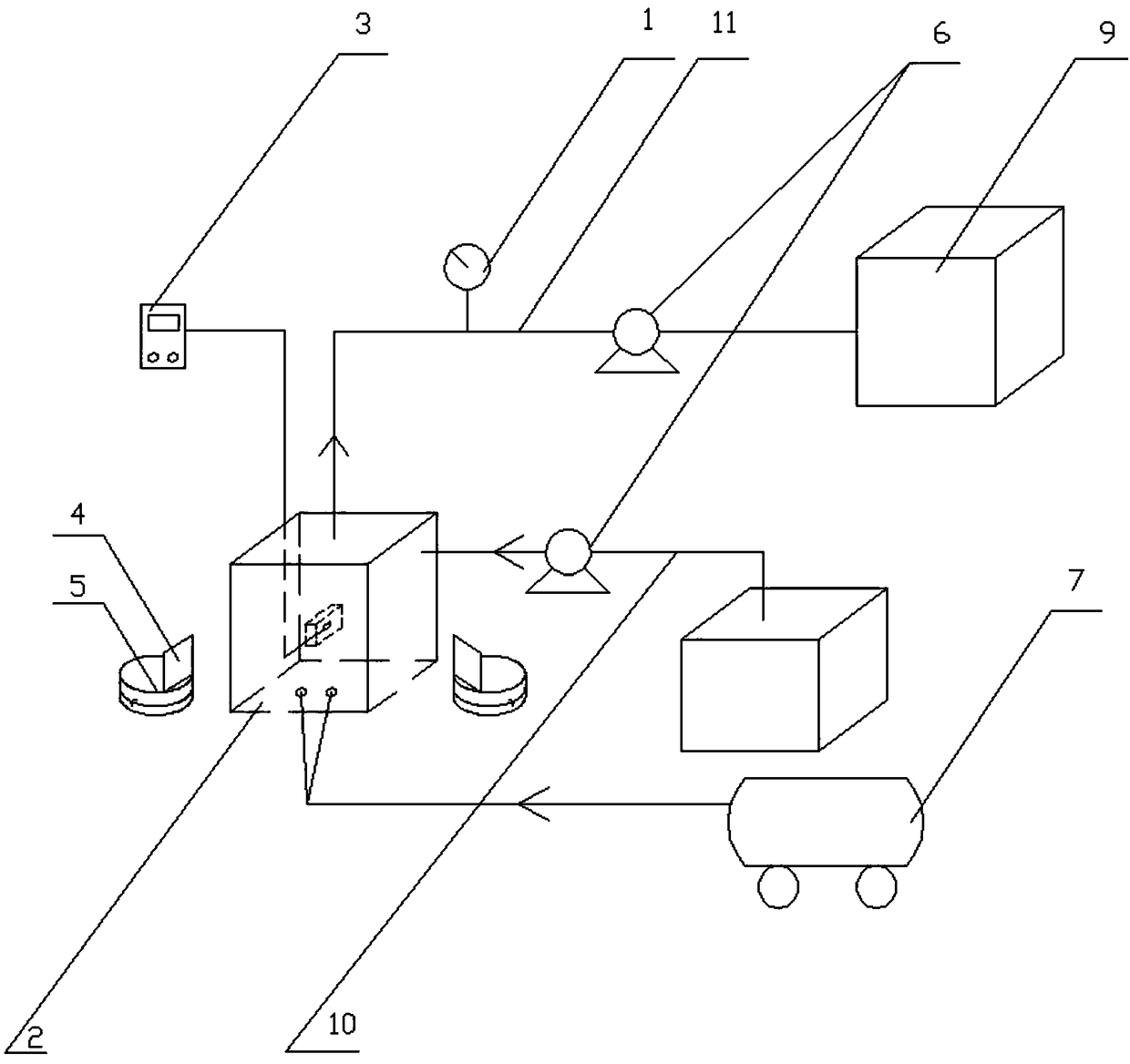

[0021] exist figure 1 and figure 2 In the schematic diagram of the present invention shown, the steps of the present invention are as follows:

[0022] (1) Sludge domestication: In the domestication container, the sludge is washed to remove aged or dead large pieces of black sludge. After 3 days of stuffy exposure, the sequential intermittent activated sludge method is used to enter and exit the water, according to the proportion 10%, 20%, 30%, 40%, 50%, and 60% of the mixed solution are discharged, and the oily sewage from the ship is used to make up. The interval is set to 3 days. The concentration of suspended solids in the liquid reaches 5000mg / L, the value of the sludge volume index reaches 100mL / g, and the two indicators tend to be stable, and the domestication of sludge cultivation is over; The bioreactor is connected to the air pump through the air pipe, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com