Combined membrane biological reaction device for micro-polluted source water treatment

A technology of membrane bioreaction and water source water, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. It can solve the problems of short service life of membrane components, poor decontamination effect of micro-polluted water, Membrane fouling and other problems, to achieve the effect of prolonging the service life, slowing down the membrane fouling rate and membrane flux decay rate, and improving the decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

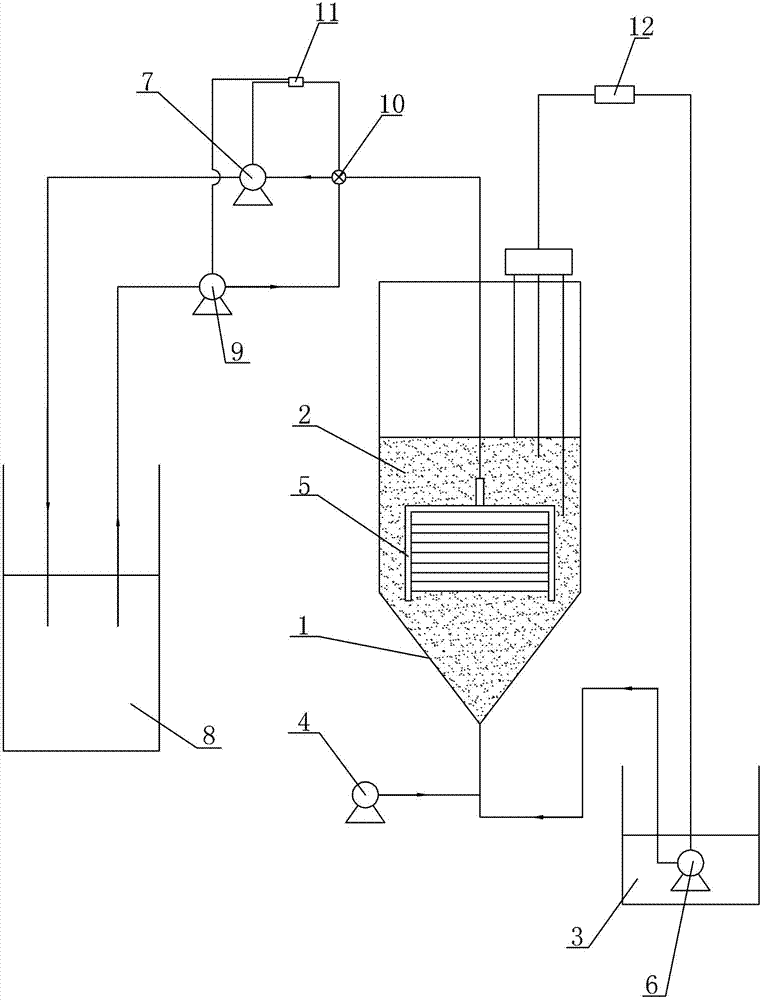

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, a composite membrane bioreactor for slightly polluted source water treatment described in this embodiment includes a reaction vessel 1, attapulgite and activated sludge mixture 2, a water distribution tank 3, an air pump 4, Membrane module 5, water inlet pump 6, water outlet pump 7 and clean water tank 8, attapulgite and activated sludge mixed solution 2 are filled in reaction vessel 1, water inlet pump 6 is connected to water distribution tank 3 through pipelines, and water inlet pump 6 is also passed through The pipeline is connected to the reaction vessel 1, the output end of the air pump 4 is communicated with the pipeline between the water inlet pump 6 and the reaction vessel 1, the membrane assembly 5 is installed in the reaction vessel 1, and the membrane assembly 5 is immersed in attapulgite and active In the sludge mixture 2, the output end of the membrane module 5 is connected to the ...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment mode, a kind of composite membrane bioreactor device that is used for micropolluted water source water treatment described in this embodiment mode also comprises backwash pump 9, electromagnetic valve 10 and time relay 11, and electromagnetic valve 10 is installed in outlet pump 7 and On the pipeline between the membrane modules 5, the input end of the backwash pump 9 is connected to the clean water tank 8 through the pipeline, the output end of the backwash pump 9 is connected to the solenoid valve 10 through the pipeline, and the two control terminals of the time relay 11 are respectively Connect with outlet pump 7 and backwash pump 9.

[0010] In this embodiment, the time relay 11 controls the time of water outlet and backwashing, and backwashing is performed for 3 minutes every 28 minutes of water outlet.

[0011] The technical effect of this embodiment is: through the control of the ti...

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a composite membrane bioreactor for micro-polluted water source water treatment described in this embodiment also includes a water level controller 12, and the water level controller 12 is installed in the mixed solution 2 of attapulgite and activated sludge , the water level controller 12 is used to control the opening and closing states of the water inlet pump 6 .

[0014] In this embodiment, when the water level in the reaction vessel 1 reaches the lowest water level, the water level controller 12 turns on the water inlet pump 6, and the reaction vessel 1 begins to enter water. When the water level reaches the highest water level, the water level controller 12 turns off the water inlet pump 6.

[0015] The technical effect of this embodiment is: the water level controller is used to control the operation of the membrane bioreactor according to the set minimum water level and maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com