Integral welded-type vertical multi-filter drum dust remover

A filter cartridge dust collector and welding technology, applied in the field of air purification, can solve the problems of troublesome adsorbent, low efficiency, large filter resistance, etc., and achieve the effects of low replacement cost, high filtration efficiency, and long replacement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

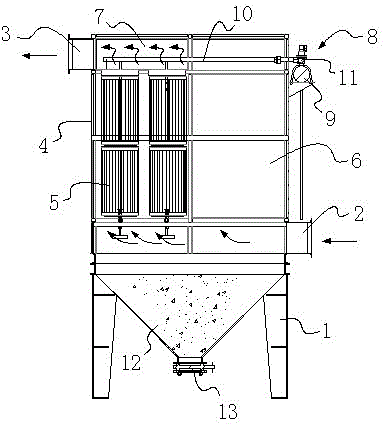

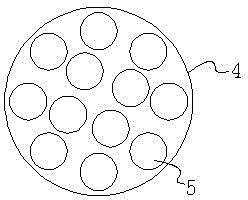

[0012] Such as figure 1 , 2 As shown, an integrally welded vertical multi-cartridge dust collector includes a frame 1 and a dust removal box 4 with a dust suction port 2 and an air exhaust port 3 arranged on the frame 1, and the dust removal box 4 is provided with There is a smoke filter area 6 with a filter cartridge 5, the smoke filter area 6 is connected to the negative pressure suction area 7 for providing suction to the exhaust port 3, the exhaust port 3 is connected to the negative pressure suction area 7, and the dust removal box 4 is equipped with a blowback control device 8 that acts on the filter cartridge 5 and knocks down the accumulated dust on the surface of the filter cartridge 5. The blowback control device 8 extends to the inside of the filter cartridge 5 from the air storage bag 9 arranged outside the dust removal box 4. Comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com