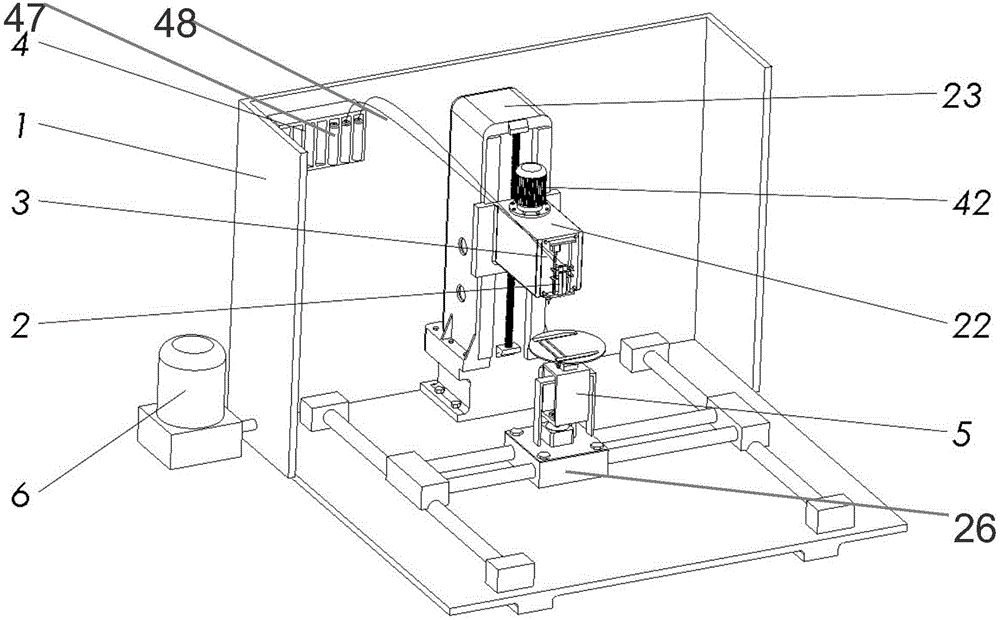

Additive manufacturing and subtractive manufacturing combination based integrated forming equipment for bionic structures

A forming equipment and bionic technology, applied in the direction of prosthesis, medical science, stent, etc., can solve the problems of low forming efficiency, non-replacement, large limitations, etc., and achieve the effect of improving forming efficiency, avoiding processing, and improving forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Forming of organ precursors: 1) Before forming the three-dimensional structure, use three-dimensional modeling software to establish a three-dimensional model, use layering processing software to layer the model, obtain the numerical control code for forming, and convert the layer file and processing parameters Input the computer control software; 2) Select the materials for the experiment. In this embodiment, the synthetic polymer polyurethane (PU) / tetraethylene glycol (Tetraglycol) solution is used as the peripheral scaffold material of the vascular system, and a certain proportion of fat stem cells and adult cells are selected. Cells, using phosphate buffered solution (PBS) containing endothelial cell growth factor (PBS) or gelatin / fibrinogen mixed solution as raw materials, prepared according to an appropriate ratio, and made into molding materials for later use; Sterilization; 4) Add different forming materials into each barrel of the raw material box of ...

Embodiment 2

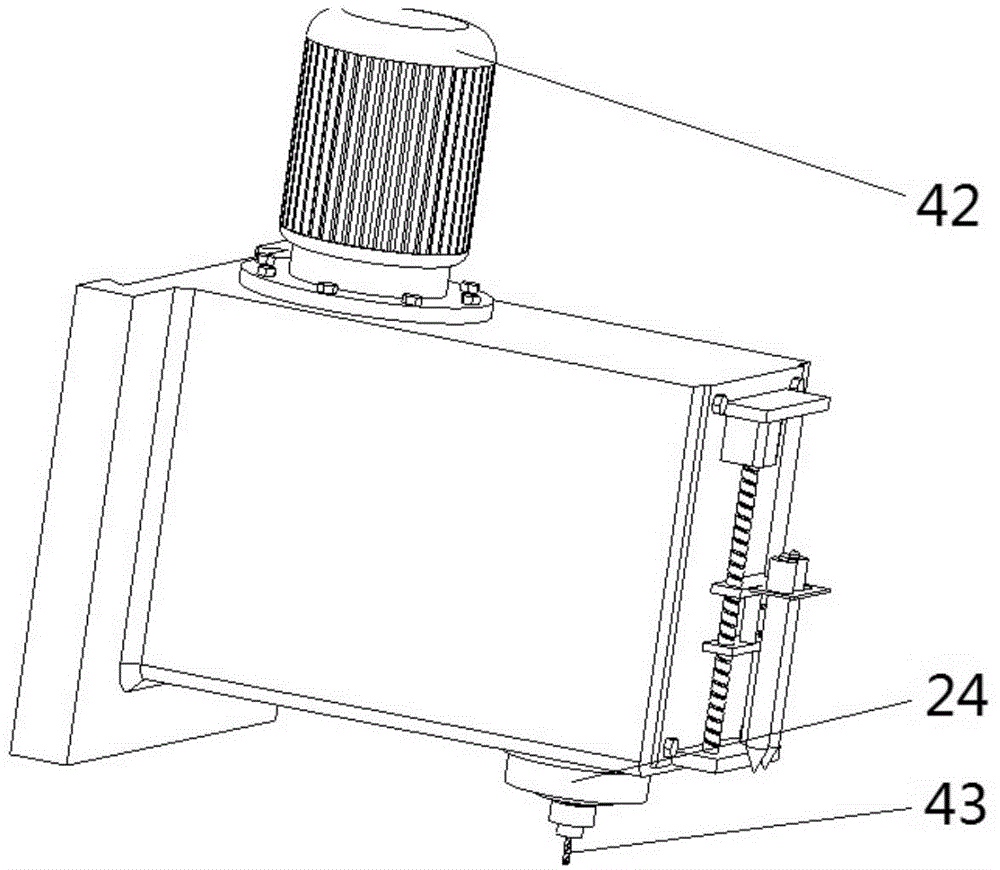

[0053] Example 2: Processing and molding of smooth round tubes filled with titanium alloy hard tissue: 1) Before forming, use 3D modeling software to build a 3D model, use layered processing software to layer the model, and obtain the NC code for forming, select For the processing plan of circular cross-section parts, set the rotation parameters of the forming table, and input the layer file and processing parameters into the computer control software; The temperature heats the barrel; 3) Set the horizontal offset between the nozzle and the center position of the forming table, and the spraying of the nozzle starts after the forming table starts to rotate; 4) After the main body is formed, it is tightened by the table holding mechanism, and the subtractive manufacturing mechanism adopts polishing 5) The forming table is deflected by 30°, and the subtractive manufacturing mechanism is sequentially replaced with a drill bit and a tap to drill oblique holes on the outer surface of...

Embodiment 3

[0054]Example 3: Forming of bone tissue repair materials: 1) Before forming, use 3D modeling software to establish a 3D model, use layering processing software to layer the model, obtain the NC code for forming, and input the layer file and processing parameters Computer control software; 2) Select polylactic acid and polyglycolic acid copolymer (PLGA) and calcium phosphate, degradable calcium phosphate bone cement and phosphorylated chitosan as experimental materials, dissolve PLGA in 1.4-dioxane solution and Mix the calcium phosphate powder evenly, put it into the cylinder with the degraded calcium phosphate bone cement and phosphorylated chitosan slurry before curing, turn on and preheat to the ejection condition; 3) Set the position of each nozzle and the forming table before starting processing Use the control and data processing system to center (knife), start the temperature control cooling device, make the temperature in the equipment drop to a certain value and maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com