RH diffusion source, and method for producing R-T-B-based sintered magnet using same

一种R-T-B、扩散源的技术,应用在电感/变压器/磁铁制造、磁性物体、磁性材料等方向,能够解决磁通密度降低等问题,达到HcJ提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1)

[0094] (Experimental example 1) (Efficiency of RH diffusion treatment)

[0095] First, an R-TB-type sintered magnet with a composition ratio of Nd=28.5, Pr=1.0, Dy=0.5, B=1.0, Co=0.9, Al=0.1, Cu=0.1, and the remainder=Fe (mass%) is produced. . By machining this, a cubic R-T-B type sintered magnet of 7.4 mm×7.4 mm×7.4 mm was obtained. When the magnetic properties of the produced R-T-B type sintered magnets are measured using a B-H tracer, the properties after heat treatment (500°C x 1 hour), H cJ 960kA / m, B r It is 1.41T. This value was used as the reference|standard of the characteristic evaluation of each experiment example below.

[0096] The RH diffusion source is produced as follows: According to the specified composition described in Table 1, Nd, Dy, Fe are weighed, and after melting in a high-frequency melting furnace, the molten metal is mixed with a copper tube made of copper that rotates at a roll surface speed of 2 m / s. The water-cooled roll contacts to form a q...

experiment example 2)

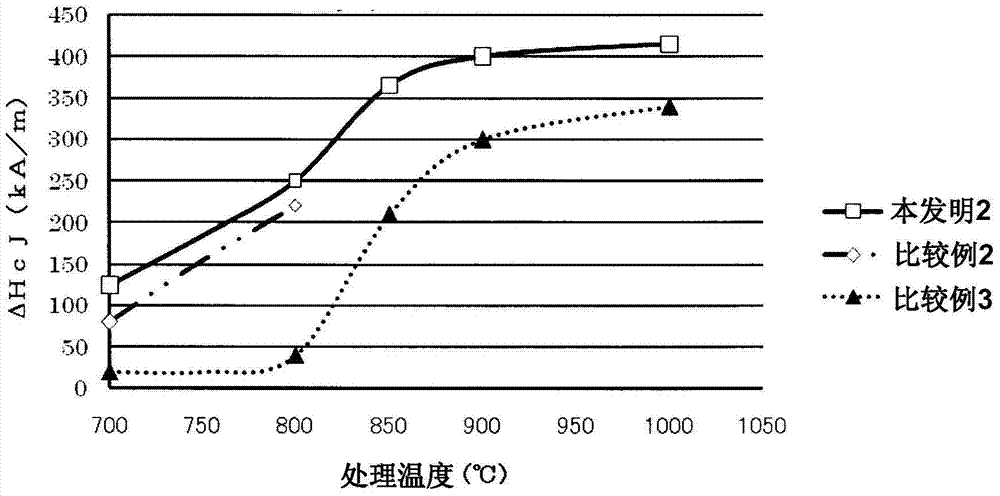

[0107] (Experimental example 2) (with or without welding, temperature of RH diffusion)

[0108] According to the conditions described in Table 3, R-TB type sintered magnets were produced, and the conditions and methods not described in Table 3 were the same as in Experimental Example 1.

[0109] Table 3 shows the results of the RH diffusion process with or without welding at different temperatures (600°C, 700°C, 800°C, 850°C, 900°C, 1000°C, 1020°C).

[0110] Samples 9 to 17 are samples using the RH diffusion source of the present invention, and samples 18 to 30 are comparative examples.

[0111] In Table 3, use "ΔH cJ ” represents the H after the RH diffusion process cJ Increment, use "ΔB r "Indicates B after the RH diffusion process r increments. A negative value indicates that the magnetic properties of the R-TB-based sintered magnet that has not been subjected to the RH diffusion treatment are lowered. In "Whether there is welding or not", "Yes" indicates that the RH ...

experiment example 3)

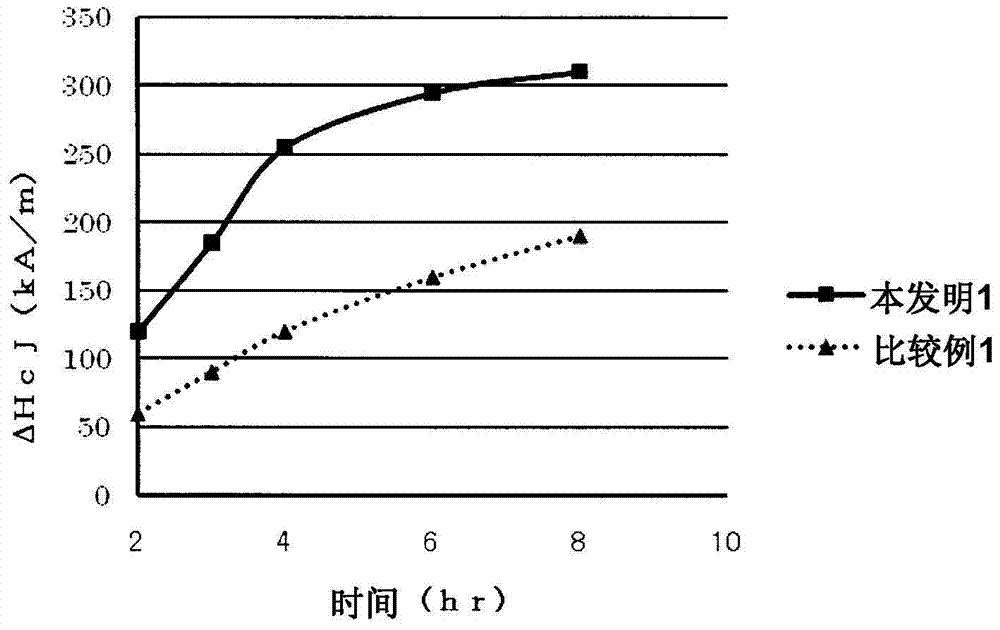

[0125] (Experimental example 3) (Influence of RH diffusion treatment time)

[0126] Except for the conditions described in Table 5, an R-TB type sintered magnet was produced under the same conditions and method as in Experimental Example 1.

[0127] Regarding the influence of the RH diffusion treatment time, when the RH diffusion treatment is performed by changing the RH diffusion treatment time as shown in Table 5, in the RH diffusion process at 900°C, after 4 hours, ΔH cJ No major changes (samples 33 to 36). Sample 31 to Sample 36 of Table 5 B r 、H cJ The value of is shown in Table 6.

[0128] [table 5]

[0129]

[0130] [Table 6]

[0131] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com