Electric heating energy-saving storage unit

A technology of thermal energy storage and memory, applied in the field of boilers, can solve the problems of increasing electricity pressure in peak power consumption areas, waste of electric energy in power plants, and increasing production costs, so as to reduce electricity pressure, prevent heat loss, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

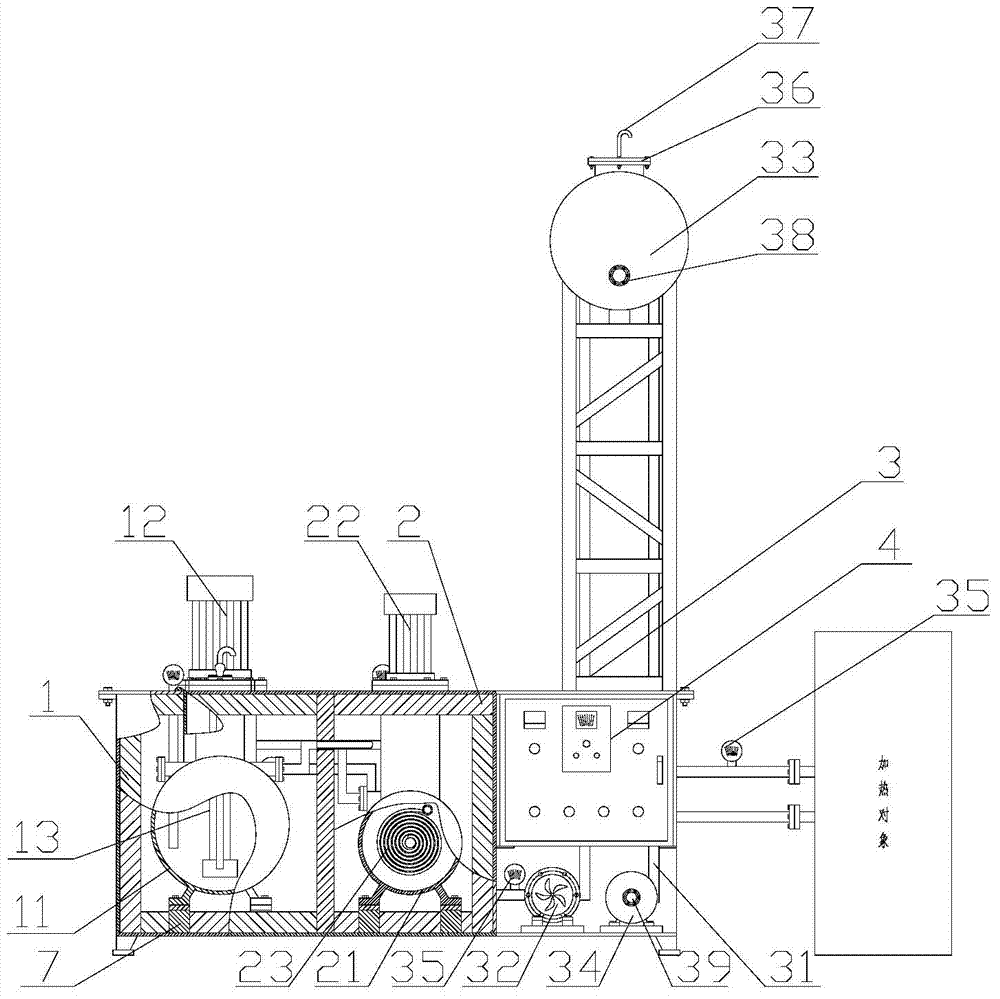

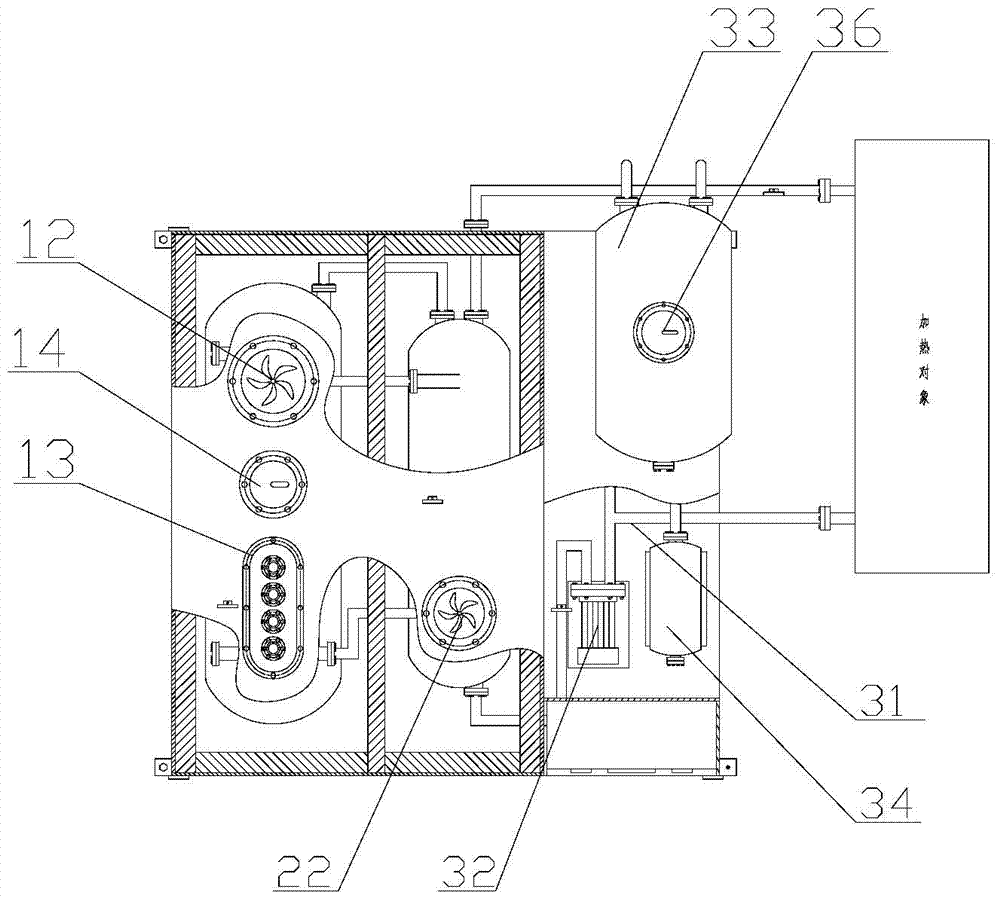

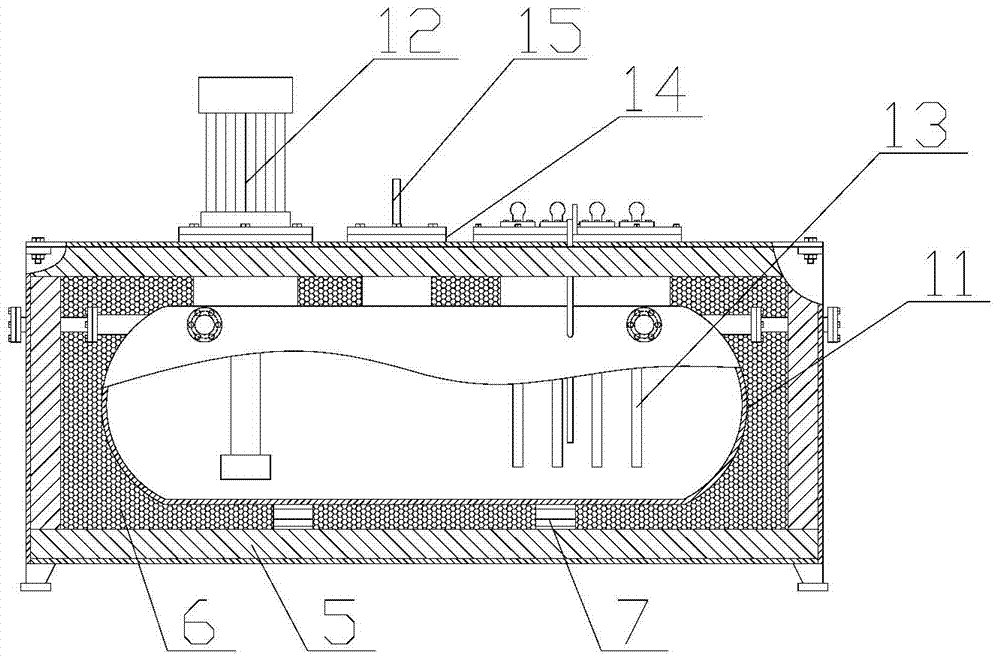

Embodiment 1

[0031] refer to figure 1 , figure 2 and image 3 , an electric heating energy-saving storage device, including an electric thermal energy storage device 1, a constant temperature heat exchanger 2 and a heat conduction oil heating device 3, and the electric thermal energy storage device 1 is composed of a heat storage tank 11 and an ultra-high temperature pump 12 arranged on the heat storage tank , electric heating wire 13, the heat storage tank 11 is filled with inorganic medium liquid, and the inorganic medium liquid can reach a stable high temperature below 550 degrees when heated under normal pressure. The electric heating wire 13 is installed above the heat storage tank 11 and inserted vertically into the Inside the heat storage tank 11, it is easy to disassemble and assemble, and it is convenient to replace the heating wire. The constant temperature heat exchanger 2 is composed of a constant temperature tank 21, a temperature control pump 22 installed on the constant te...

Embodiment 2

[0041] refer to figure 1 , figure 2 , an electric heating energy-saving storage device, including an electric thermal energy storage device 1, a constant temperature heat exchanger 2 and a heat conduction oil heating device 3, and the electric thermal energy storage device 1 is composed of a heat storage tank 11 and an ultra-high temperature pump 12 arranged on the heat storage tank , electric heating wire 13, the heat storage tank 11 is filled with inorganic medium liquid, and the inorganic medium liquid can reach a stable high temperature below 550 degrees when heated under normal pressure. The electric heating wire 13 is installed above the heat storage tank 11 and inserted vertically into the Inside the heat storage tank 11, it is easy to disassemble and assemble, and it is convenient to replace the heating wire. The constant temperature heat exchanger 2 is composed of a constant temperature tank 21, a temperature control pump 22 installed on the constant temperature tank...

Embodiment 3

[0044] refer to figure 1 , figure 2 , image 3 , Figure 4 , an electric heating energy-saving storage device, including an electric thermal energy storage device 1, a constant temperature heat exchanger 2 and a heat conduction oil heating device 3, and the electric thermal energy storage device 1 is composed of a heat storage tank 11 and an ultra-high temperature pump 12 arranged on the heat storage tank , electric heating wire 13, the heat storage tank 11 is filled with inorganic medium liquid, and the inorganic medium liquid can reach a stable high temperature below 550 degrees when heated under normal pressure. The electric heating wire 13 is installed above the heat storage tank 11 and inserted vertically into the Inside the heat storage tank 11, it is easy to disassemble and assemble, and it is convenient to replace the heating wire. The constant temperature heat exchanger 2 is composed of a constant temperature tank 21, a temperature control pump 22 installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com