Preparation method of structure-controllable magnesium-based three-dimensional porous material

A technology of three-dimensional porous and porous materials, applied in the field of materials, can solve the problems of high equipment requirements, high cost, difficult adjustment of porous material pore size and pore shape, etc., and achieve the effect of accurate and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

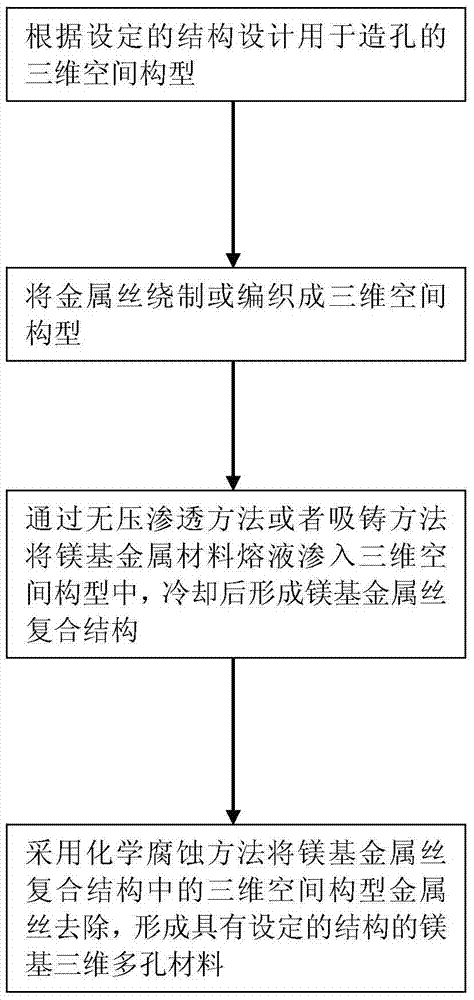

[0018] Such as figure 1 As shown, the preparation method of the structure-controllable magnesium-based three-dimensional porous material of the present invention includes the following contents:

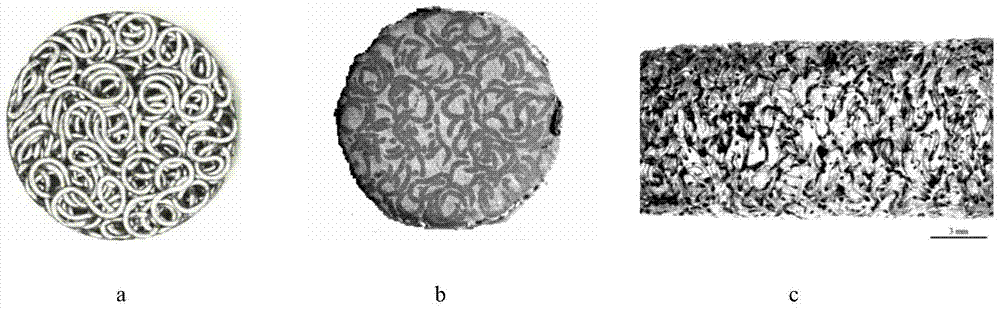

[0019] First, design the three-dimensional space configuration for pore formation according to the set structure of the magnesium-based three-dimensional porous material to be prepared, and the porosity of the set structure is selected in the range of 5%-95%; then the metal wire is wound or Woven into this three-dimensional configuration, see figure 2 a. The metal wire is a metal wire such as iron wire, titanium wire or aluminum wire, with a diameter of 0.005mm-5mm; afterwards, the molten magnesium-based metal material is infiltrated into the three-dimensional configuration by pressureless infiltration or suction casting methods, After cooling to form a magnesium-based metal wire composite structure, see figure 2 b; Finally, a chemical corrosion method is used to remove the three-dimen...

example 1

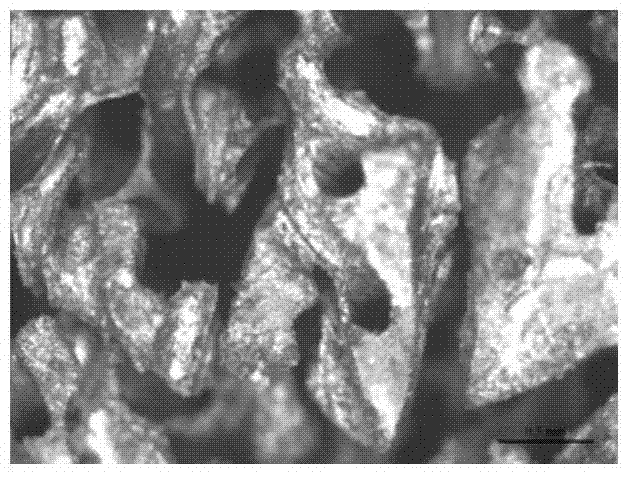

[0022] According to the set structure of the magnesium-based three-dimensional porous material to be prepared, the three-dimensional space configuration for pore formation is designed, and the porosity of the set structure is 5%; then the iron wire with a diameter of 0.005mm is woven into the set structure and 95 % Porosity three-dimensional space configuration; through the suction casting technology, the Mg-RE alloy melt is injected into the three-dimensional space configuration, and the magnesium-based metal wire composite structure is formed after cooling; the magnesium-based metal wire composite structure is placed in the HF solution Soaked in medium for more than 72 hours, the iron wire in it is completely corroded and dissolved, forming a Mg-RE three-dimensional porous material with a porosity of 5%. Its compressive strength is 300MPa, and the elastic modulus is 40GPa. It is suitable for heat exchange, purification and filtration. .

example 2

[0024] According to the set structure of the magnesium-based three-dimensional porous material to be prepared, the three-dimensional space configuration for pore formation is designed, and the porosity of the set structure is 47%; then the titanium wire with a diameter of 0.26 mm is used to prepare it with a winding machine. Set the structure and the three-dimensional space configuration with 53% porosity; through the pressureless infiltration technology, infiltrate the medical pure magnesium melt into the three-dimensional space configuration, and form a magnesium-based metal wire composite structure after cooling; the magnesium-based metal wire The composite structure is immersed in HF solution for more than 72 hours, so that the titanium wire in it is completely corroded and dissolved, forming a Mg three-dimensional porous material with a porosity of 47%. Its compressive strength is 4.88MPa and elastic modulus is 0.24GPa, which is suitable for biological Fields such as medici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com