Lubricating oil containing illite/montmorillonite clay nano powder and preparation method thereof

A technology of nano-powder and smectite clay, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve problems such as unsatisfactory anti-wear and anti-friction effects, and achieve environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of slurry: Mechanically crush natural I / Mongolian clay minerals into small pieces of I / Mongolian clay ore with a particle size of less than 5cm; mix 450g of I / Mongolian clay with 550g of water, and then soak for 12 hours to obtain I / Mongolian clay ore Mongolian clay slurry;

[0035] (2) Dispersion: Use 0.1mol / L NaOH solution to adjust the pH value of the Iraqi / Mongolian clay slurry to 9, add 6.75g of dispersant WF-211, and use a sand mill disperser for slurry dispersion; among them, the dispersant The addition of WF-211 is 1.5wt% of the solid content in the slurry; the speed of the sand mill disperser is 1000rpm, and the stirring time is 30min;

[0036] (3) Screening: pass the slurry dispersed in step (2) through a 500-mesh sieve to obtain the under-screen slurry;

[0037] (4) Grinding: Grinding the under-screen slurry with a high-energy-density stirring mill, in which the feeding speed of the pump is 3L / min, and the grinding medium is ZrO with a diamet...

Embodiment 2

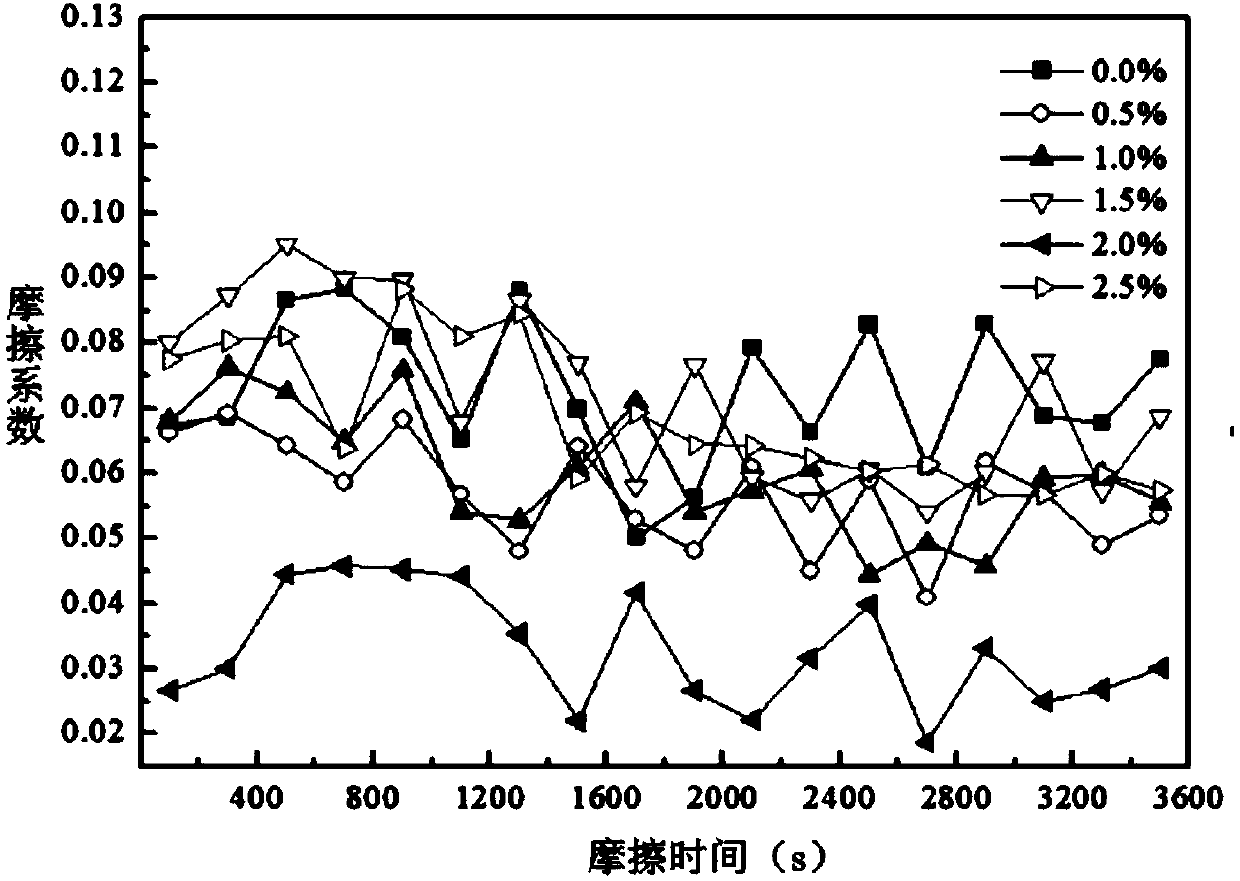

[0042] The difference between this example and Example 1 is that the grinding time in step (4) is 3h, and the particle cumulative distribution of the prepared nano-slurry is as follows figure 1 As shown in the 3h curve, it can be seen that particles smaller than 100nm account for about 67%, and the particle size reaches the nanometer level; in step (7), take 2g of modified Il / Mongolian clay nanopowder and 198g of Group III base oil to prepare Lubricating oil containing 1.0wt% mass fraction of I / Mon clay nanopowder.

Embodiment 3

[0044] The difference between this example and Example 1 is that the grinding time in step (4) is 4 hours, and the particle cumulative distribution of the slurry is as follows figure 1As shown in the 4h curve in the middle, it can be seen that the particles smaller than 100nm account for about 70%, and the particle size reaches the nanometer level; in step (7), take 3g of the modified Iraqi / Mongolian clay nanopowder and 197g of Group III base oil to prepare Lubricating oil containing 1.5wt% mass fraction of I / Mon clay nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com