Preparation method of water-soluble upconversion fluorescent nano material

A fluorescent nanomaterial and water-soluble technology, which is applied in the direction of luminescent materials, nanotechnology, chemical instruments and methods, etc., can solve the problems affecting the application of biomarker materials, low up-conversion luminous intensity, and complicated pretreatment operations, etc., to achieve suitable Suitable for mass production, safe and non-toxic reaction process, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

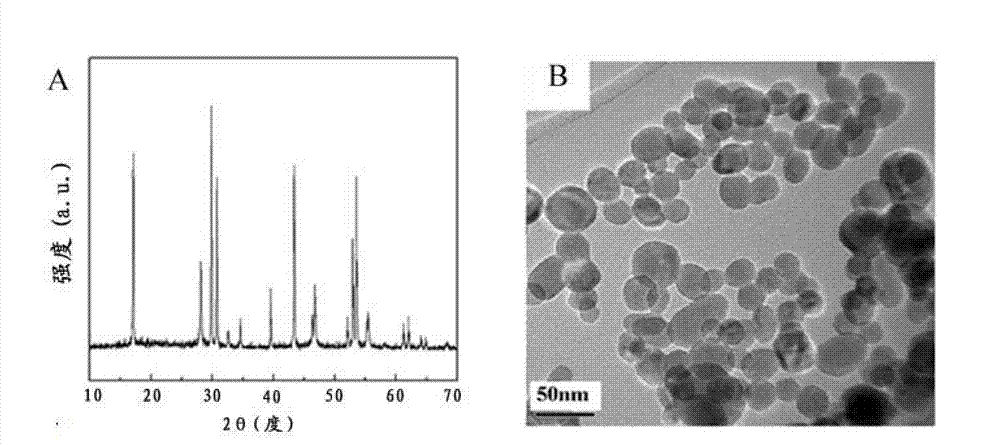

[0035] Take 2ml of rare earth nitrate solution (the molar ratio of each rare earth ion is yttrium ion:ytterbium ion:erbium ion=80:18:2), add 12ml of absolute ethanol to it, and then add 0.9000g polyacrylic acid (polyacrylic acid and total Rare earth ion molar ratio is 1:1) aqueous solution 14ml, stir for 10min; then add 0.2100g sodium fluoride (fluoride ion to total rare earth ion molar ratio is 10:1) aqueous solution 8ml, after stirring for 20min, place in In a high-pressure reactor, react at 200 ° C for 10 h under stirring conditions; stop heating and keep stirring to cool to room temperature, centrifuge to separate the solid product, wash 3 times with absolute ethanol and ultrapure water, and vacuum dry at room temperature for 12 h to obtain a solid Up-conversion fluorescent material, its X-ray diffraction spectrum (XRD) and transmission electron microscope (TEM) are as follows figure 1 shown; figure 1 The X-ray diffraction pattern of A shows that the material is a mixed c...

Embodiment 2

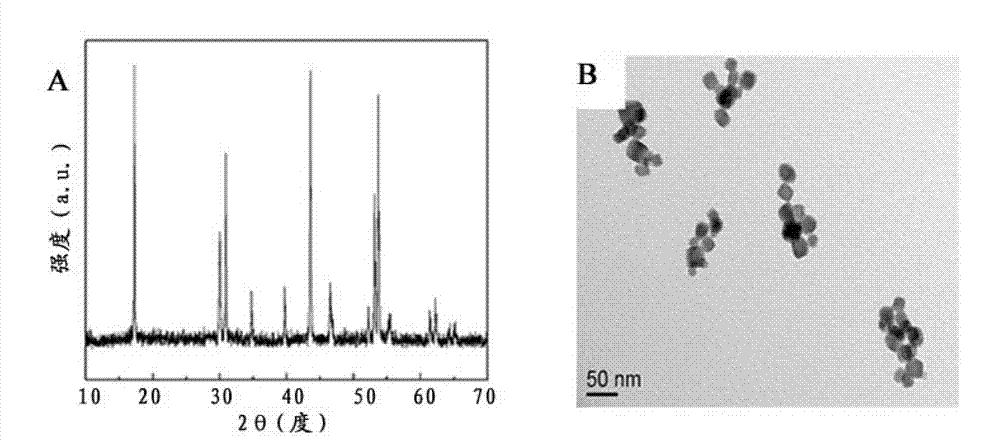

[0037] Take 2 ml of rare earth nitrate solution (the molar ratio of each rare earth ion is yttrium ion: ytterbium ion: erbium ion = 80:18:2), add 18 ml of absolute ethanol to it, and then add 0.9000 g of polyacrylic acid (polyacrylic acid and total 8ml of an aqueous solution containing 0.2100g of sodium fluoride (the molar ratio of fluoride ions to total rare earth ions is 10:1) was added, stirred for 10min, stirred for 20min, and placed in In a high-pressure reactor, react at 200 ° C for 10 h under stirring conditions; stop heating and keep stirring to cool to room temperature, centrifuge to separate the solid product, wash 3 times with absolute ethanol and ultrapure water, and vacuum dry at room temperature for 12 h to obtain a solid Up-conversion fluorescent material, its X-ray diffraction spectrum (XRD) and transmission electron microscope (TEM) are as follows figure 2 shown; figure 2 The X-ray diffraction pattern of A shows that the material is a mixed crystal phase of...

Embodiment 3

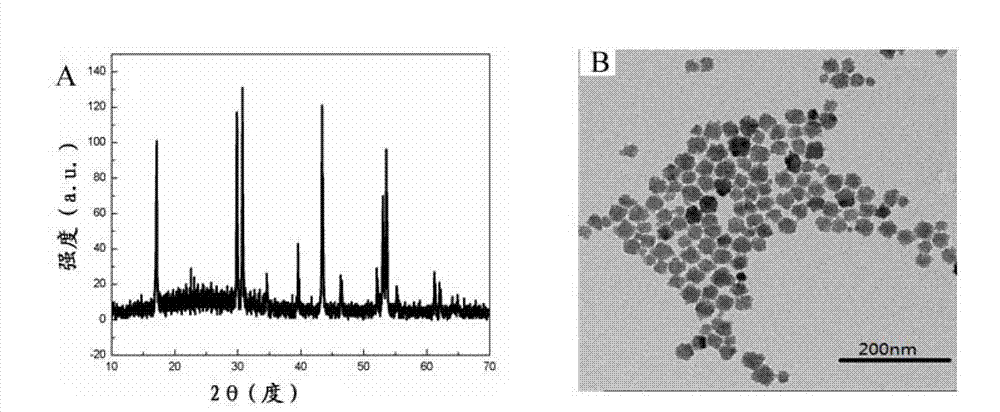

[0039] Take 2 ml of rare earth nitrate solution (the molar ratio of each rare earth ion is yttrium ion: ytterbium ion: erbium ion = 80:18:2), add 18 ml of absolute ethanol to it, and then add 0.340 g of polyethyleneimine (polyethyleneimine Add 8ml of an aqueous solution containing 0.2100g of sodium fluoride (the molar ratio of fluoride ions to total rare earth ions is 10:1) and stir for 10 minutes. After 20 minutes, put it in a high-pressure reactor, and conduct a hydrothermal reaction at 240°C for 10 hours under stirring; stop heating and keep stirring to cool to room temperature, centrifuge to separate the solid product, wash 3 times with absolute ethanol and ultrapure water, Vacuum drying at room temperature for 12 hours to obtain a solid up-conversion fluorescent material, its X-ray diffraction spectrum (XRD) and transmission electron microscope (TEM) as image 3 shown; image 3 The X-ray diffraction spectrum of A shows that the material is a pure hexagonal crystal phase;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com