Novel photo-curing formaldehyde removing environment-friendly coating and preparation method of novel photo-curing formaldehyde removing environment-friendly coating

An environmentally friendly coating and light-curing technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as increasing the safety risk of home environment, containing formaldehyde, etc., to improve environmental hygiene and safety, and to achieve fast drying speed. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

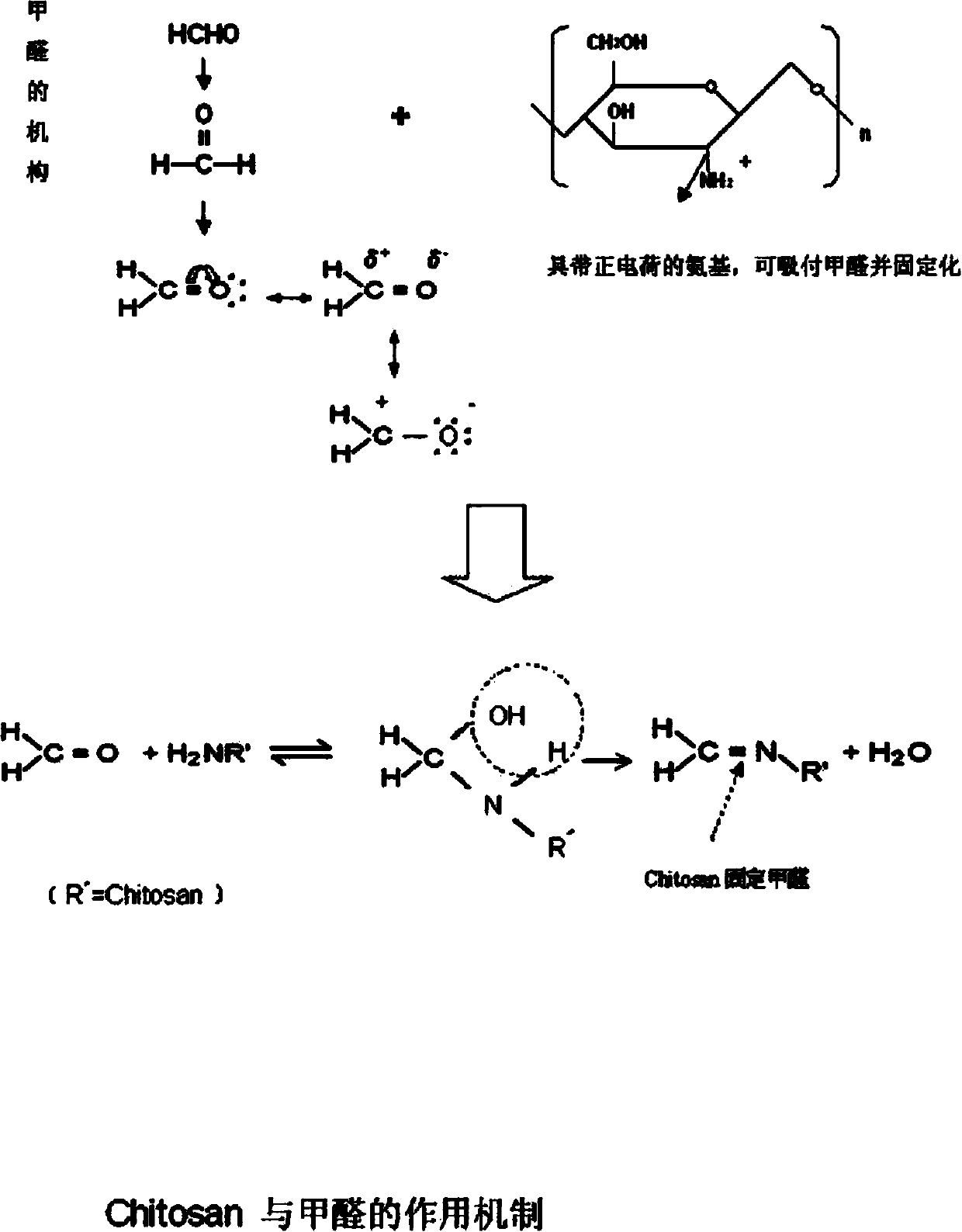

Method used

Image

Examples

Embodiment 1

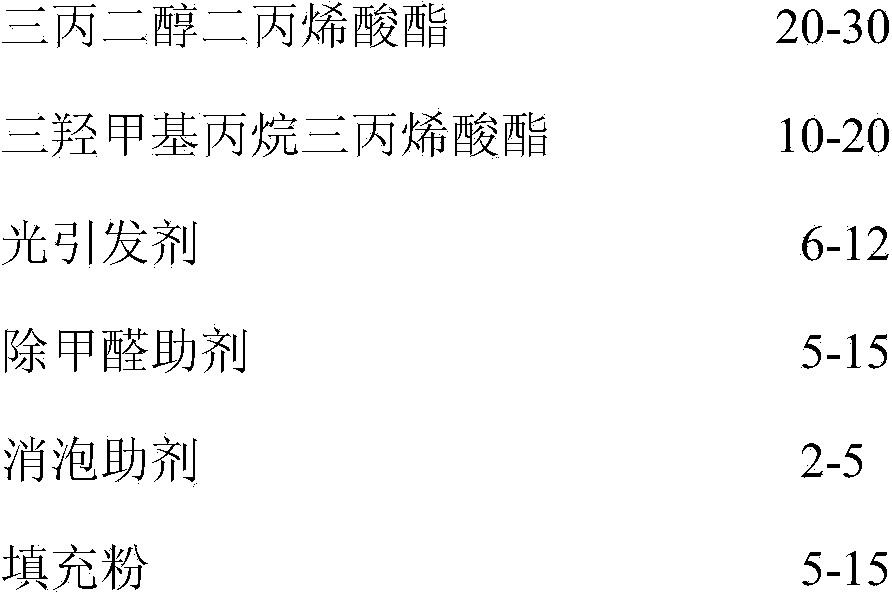

[0028]

[0029]

[0030] Embodiment one preparation mode:

[0031] Step 1: Stir and dissolve tripropylene glycol diacrylate, trimethylolpropane triacrylate and photoinitiator at a temperature of 45 degrees.

[0032] Step 2: Add polyurethane acrylic resin and epoxy acrylic resin to the prepared mixture in sequence and stir to disperse evenly.

[0033] Step 3: Divide the filling powder into three equal parts and add in batches, and make it completely dispersed evenly. Until there is no suspension or sedimentation.

[0034] Step 4: Stir the formaldehyde-removing additive, defoaming additive, and hydroxyethyl methacrylate to disperse evenly, then add it to the previously dispersed mixture, and stir evenly until there is no suspension or precipitation.

Embodiment 2

[0036]

[0037] Embodiment two preparation methods:

[0038] Step 1: Stir and dissolve 1,6-hexanediol diacrylate, trimethylolpropane triacrylate and photoinitiator at a temperature of 45 degrees.

[0039] Step 2: Add polyurethane acrylic resin and epoxy acrylic resin to the prepared mixture in sequence and stir to disperse evenly.

[0040] Step 3: Divide the filling powder into three equal parts and add in batches, and make it completely dispersed evenly. Until there is no suspension or sedimentation.

[0041] Step 4: Stir the formaldehyde-removing additive, defoaming additive, and hydroxyethyl methacrylate to disperse evenly, then add it to the previously dispersed mixture, and stir evenly until there is no suspension or precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com