Umbrella-dedicated water-based ink for terylene plain fabrics and coating method thereof

A water-based ink and fabric technology, which is applied in the field of umbrella surface processing and umbrella making, can solve the problems of water-based ink patterns that are difficult to dry quickly, the pattern adhesion fastness is not up to standard, and difficult to color, so as to reduce the residue of toxic chemicals on the umbrella surface and improve Production environment, color stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

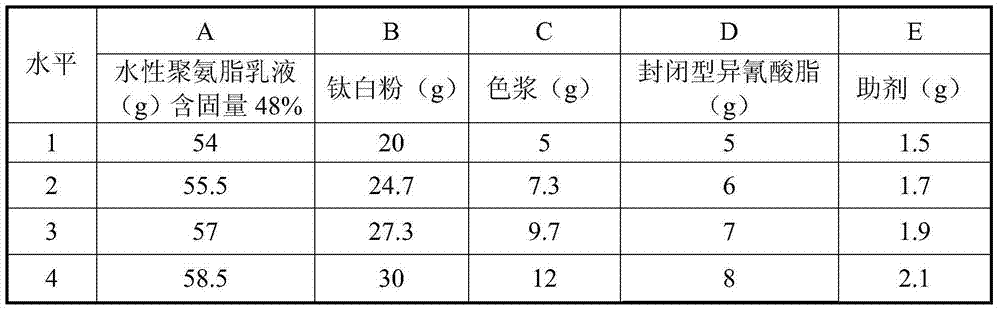

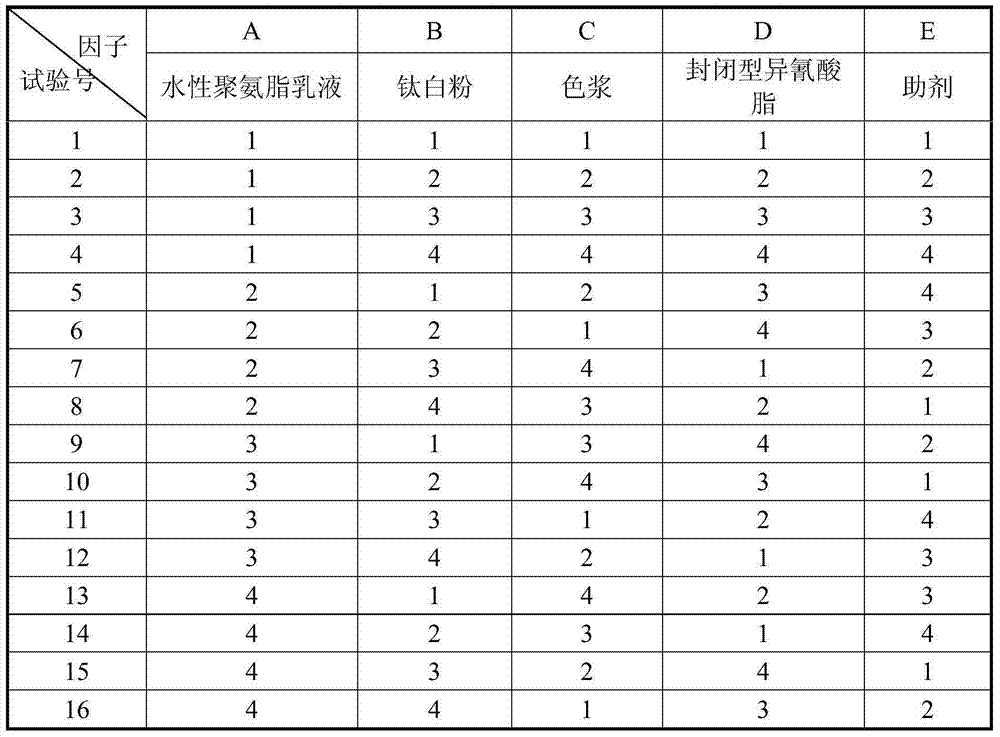

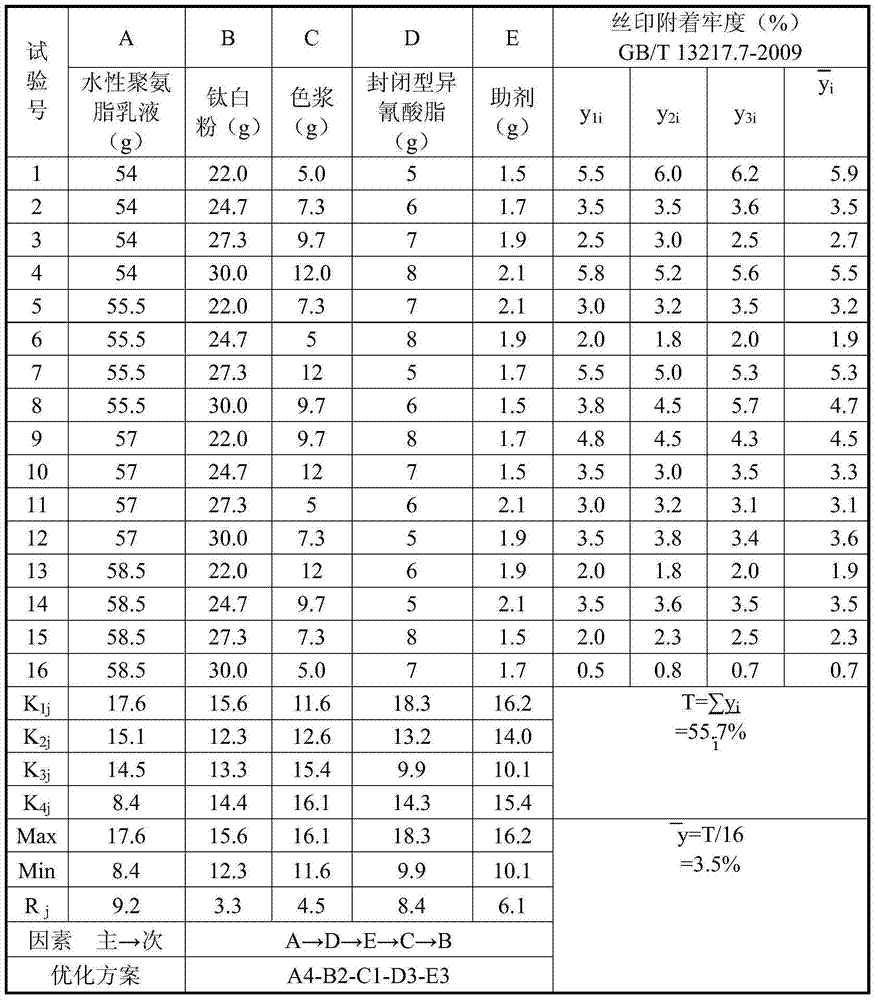

[0036] A kind of umbrella water-based ink of the present invention, selects water-based polyurethane emulsion (54-58.5) g, titanium dioxide (20-30) g, color paste (5-12) g, blocked isocyanate (5) g according to the weight ratio ~8) g, dispersant (0.5-0.7) g, defoamer (0.5-0.7) g, other additives (0.5-0.7) g to make water-based ink. Use the DOE method to select the optimal formula of HBS water-based ink suitable for polyester umbrella screen printing. The level first sets the maximum and minimum values according to the water-based ink, and the intermediate parameters are designed according to the arithmetic sequence. This test design has five factors and four levels. Choose L 16 (4 5 ) orthogonal test, see Table 1, Table 2 and Table 3 for the specific implementation of the test. The adjuvants in the table include equal amounts of dispersant, defoamer and other adjuvants.

[0037] Table 1 Formulation factors and levels of polyester fabric-based water-based inks

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com