Special material for water supply pipe used in mine

A technology for special materials and water pipes, which is applied in the field of special materials for mine water pipes. It can solve the problems of heavy weight of concrete pipes, difficulties in transportation and installation, and easy generation of static electricity. It achieves excellent flame retardancy and safety performance, saves corrosion and descaling The cost, the effect of small conveying resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

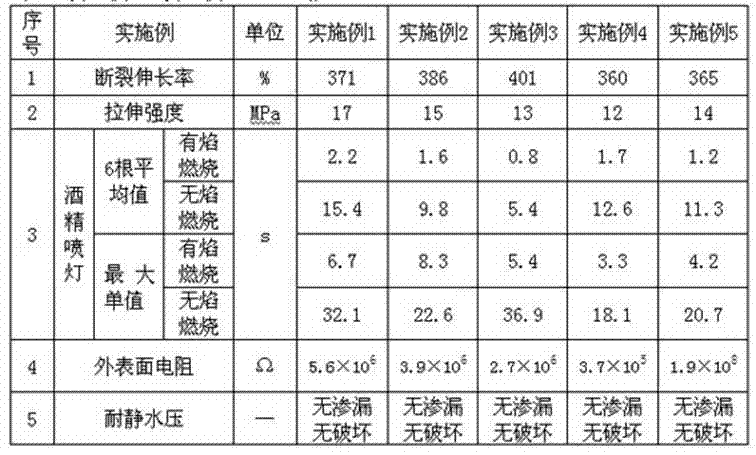

Examples

preparation example Construction

[0018] 2. Preparation of special flame retardant masterbatch for polyethylene resin:

[0019] The special flame retardant masterbatch for polyethylene resin is made of the following raw materials: linear low density polyethylene resin 25kg, microencapsulated red phosphorus (flame retardant) 75kg, chlorinated polyethylene (compatibilizer) 6㎏, N, N`—ethylene bisstearamide (dispersant) 2kg, polyethylene low molecular weight wax (lubricant) 2kg, add flame retardant, compatibilizer, dispersant, lubricant to high-speed mixer After mixing for 25 minutes at 60°C, add the base resin to a high-speed mixer and mix for 30 minutes, then put the fully mixed material into a twin-screw extruder for plasticizing and extruding, cool and granulate, and prepare a special flame-retardant masterbatch for polyethylene resin stand-by. Among them, the temperature setting of each section of the twin-screw extruder is: zone 1: 160°C, zone 2: 170°C; zone 3: 170°C; zone 4: 185°C; zone 5: 195°C. Host spe...

Embodiment 1

[0022] Weigh 65kg of high-density polyethylene resin according to the proportion; 20kg of reinforced masterbatch (reinforcing agent) for polyethylene resin; 5kg of conductive carbon black (colorant); 10kg of flame-retardant masterbatch for polyethylene resin (flame retardant) ㎏; N-(3-dodecyloxy-2-hydroxypropyl) ethanolamine (antistatic agent) 1 ㎏; calcium stearate (processing aid) 0.5 ㎏. Add polyethylene resin, reinforcing agent, coloring agent, flame retardant, antistatic agent, and processing aid into the high-speed mixer according to the above ratio, and the speed of the mixer is set at 800-1000 r / min, and after mixing for 10-30min , the above mixture is plasticized and extruded by a twin-screw extruder, cooled and granulated to obtain a special material for mine water delivery pipes. Among them, the temperature of each zone of the twin-screw extruder barrel is zone 1: 160°C, zone 2: 175°C, zone 3: 180°C, zone 4: 195°C, zone 5: 205°C. Host speed: 800-1200 r / min.

Embodiment 2

[0024] Weigh 65 kg of high-density polyethylene resin according to the proportion; 15 kg of reinforced masterbatch (reinforcing agent) for polyethylene resin; 5 kg of conductive carbon black (colorant); 15 kg of flame retardant master batch for polyethylene resin (flame retardant) ㎏; N-(3-dodecyloxy-2-hydroxypropyl) ethanolamine (antistatic agent) 1 ㎏; calcium stearate (processing aid) 0.5 ㎏. After mixing polyethylene resin, reinforcing agent, coloring agent, flame retardant, antistatic agent and processing aid at the above ratio at 800-1000 r / min for 10-30 minutes, the above mixture is plasticized and extruded by a twin-screw extruder. Extrusion, cooling and granulation to produce special materials for mine water delivery pipes. Among them, the temperature of each zone of the twin-screw extruder barrel is zone 1: 160°C, zone 2: 175°C, zone 3: 180°C, zone 4: 195°C, zone 5: 205°C. Host speed: 800-1200 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com