OCA optical adhesive tape and making method thereof

A technology of optical glue, synthesis method, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0016] Experimental example 1 Synthesis of polyurethane acrylate prepolymer

[0017] The present invention selects polyethylene glycol, toluene diisocyanate (TDI), hydroxyethyl methacrylate (HEMA), butyltin dilaurate, hydroquinone and butyl acrylate as raw materials for synthesizing polyurethane acrylate prepolymer. Among them, polyethylene glycol provides the molecular structure of the soft segment, which provides flexibility for the overall performance of the polyurethane acrylate prepolymer. TDI provides the molecular structure of the hard segment and contributes to the performance of polyurethane. HEMA is the prepolymer end cap and introduces double bonds into the molecular chain. Butyl tin dilaurate is used as the positive catalyst for the product, p-diphenol is used as the polymerization inhibitor, and butyl acrylate is used as the catalyst. The ester acts as a solvent, controls the viscosity of the system, and can be cured in the formulation.

[0018] Synthetic formula...

experiment example 2

[0029] Experimental example 2 Production of OCV optical tape.

[0030] OCV optical adhesive formula: urethane acrylate prepolymer synthesized in Experimental Example 1: 100; compounding agent: 2; initiator: 5; accelerator: 2; co-accelerator: 0.3; stabilizer: 0.01.

[0031] Wherein, the compounding agent is acrylic acid, the initiator is cumene peroxide, the accelerator is triethylamine, the auxiliary accelerator is saccharin, and the stabilizer is benzoquinone.

[0032] The adhesive mixture prepared according to the adhesive formula of this experimental example is coated on the layer of the heavy peeling PET release film, and the thickness is controlled at 0.05 mm plus or minus 0.003 mm. Dry at 80°C for 5 minutes, then lightly peel off the PET release film and stick it on the surface, and then place it in an oven at 50°C for 2 days to obtain the OCA optical tape sample.

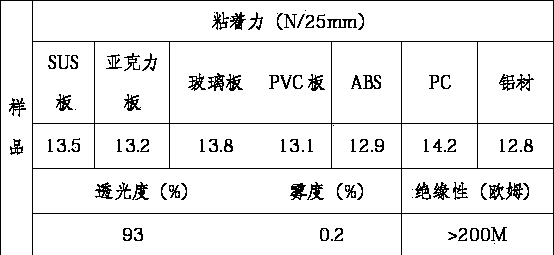

[0033] The performance of the optical tape produced by the test is described in the following table:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com