Conically sealed microjet homogenizing valve

A technology of jet valve and microporous flow channel, which is applied in the direction of fluid mixer, dissolution, mixer, etc., and can solve the problems of small processing capacity and limited wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

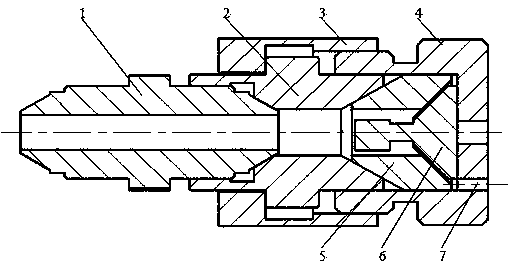

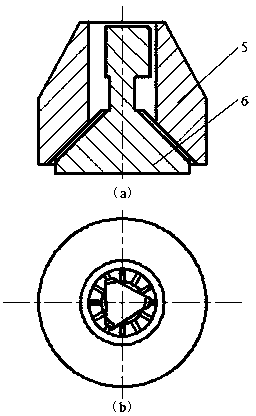

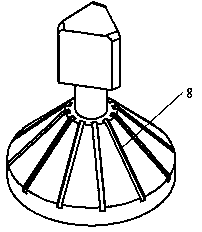

[0012] see figure 1 and figure 2 , the cone-sealed micro-channel homogeneous valve disclosed in the present invention is composed of a valve core 5 and a valve seat 6 closely matched by a conical surface. The tapered surface of the ring 2 is against the end face of the sleeve 4, and the sleeve 4 and the top ring 2 are locked by the lock nut 3, and the valve core 5 and the valve seat 6 are pressed laterally.

[0013] After the valve seat 6 is attached to the valve core 5 and pressed tightly by the lock nut 3, the micro-channel is isolated from each other at the linear seal of the tapered surface between the valve seat 6 and the valve core 5, and the micro-size of the micro-channel is maintained, thereby Ensure the miniaturization effect of material handling. The feed liquid is pressurized and passes through the micro-channels radially distributed along the cone surface at high speed, and then collides with the inner wall of the sleeve 4, and is collected and discharged by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com