Circular micro-bubble generating device

A micro-bubble generating device and micro-bubble generating technology are applied in watering devices, sustainable biological treatment, renewable energy machines, etc., which can solve problems such as high price and inconvenient maintenance, and achieve low efficiency, environmental protection, and reduction of energy consumption. Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

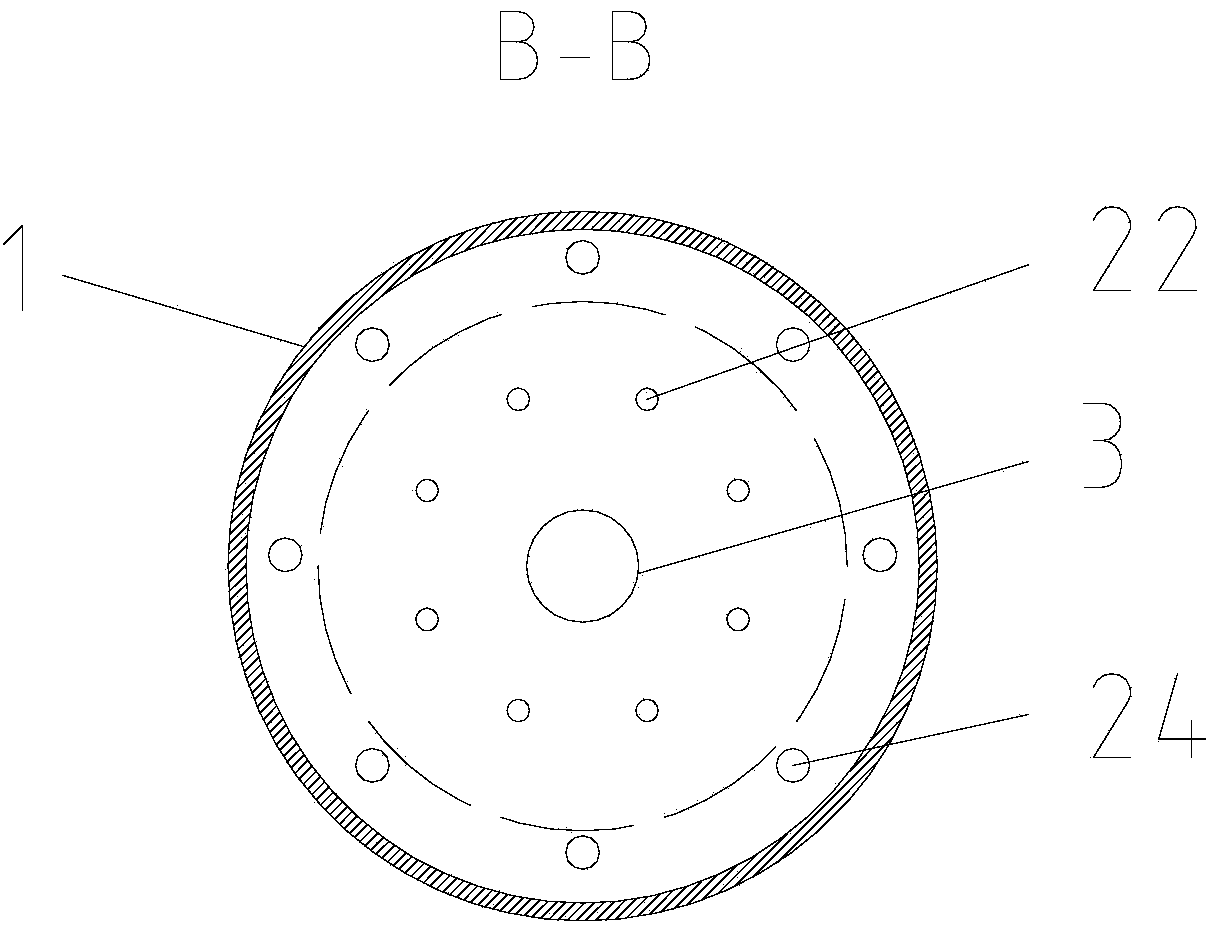

[0023] see figure 1 and Figure 4 , the circulating microbubble generating device in the illustration includes a microbubble generating chamber 1, a pressure chamber 5, a circulation pipeline 10 and a Venturi tube microbubble generator 2; Connected to form an annular channel, wherein, the microbubble generation chamber 1 communicates with the pool 17 through the water inlet pipe 18 and the water pump 16, and the pressure chamber 5 communicates with the irrigation main pipe 7; the Venturi tube microbubble generator 2 is arranged in the microbubble generation chamber 1 and It communicates with the gas filling pump 11 through the vent pipe 3, the circulation pipe 10 is provided with a front valve 14, the irrigation main pipe 7 is provided with a rear valve 8, and the microbubble generation chamber 1 and the pressure chamber 5 are respectively provided with a front pressure gauge 15 and a rear pressure gauge. Table 9, wherein the front pressure gauge 15 is located at the junction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com