Cordyceps militaris nano whole wheat flour instant electuary and production method thereof

A production method and technology of Cordyceps militaris are applied in directions such as pharmaceutical formulations, bulk transportation, plant raw materials, etc., can solve the problems of time and environmental limitations, gastrointestinal discomfort for consumers, inconvenience, etc., and achieve good instant solubility and high absorption. , instant and good dispersion, the effect of increasing the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

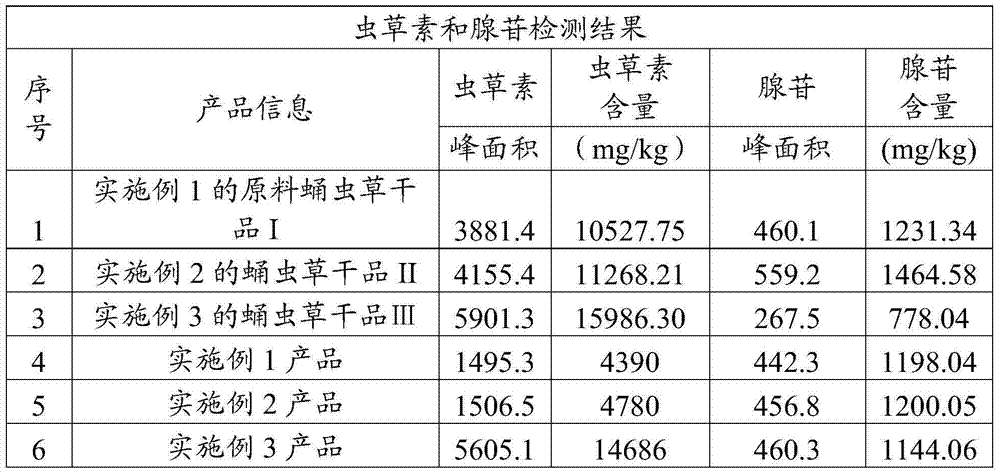

Examples

Embodiment 1

[0026] 1) The fresh fruiting body of Cordyceps militaris was processed by vacuum freeze-drying. The parameters of vacuum freeze-drying were: pre-cooling temperature -40°C, vacuum degree 10Pa, drying time 6 hours, and dried Cordyceps militaris was made. This step adopts the desktop freeze-drying machine produced by Jinan Beisi Biotechnology Co., Ltd. to carry out vacuum freeze-drying. The freeze-drying machine model: FD-1B-50, voltage 220V, frequency 50Hz, power 850W, each processing 500 grams of fresh Cordyceps militaris .

[0027] 2) Take the dry product of Cordyceps militaris in step 1) and carry out nano-crushing into particles with a particle size of about 300 nanometers. During the crushing process, a CJM-SC-B type high-energy nano-impact mill is used. The equipment has a cooling system, and the minimum freezing temperature is -15°C , in this step, keep the temperature of the material in the tank at 10°C.

[0028] 3) According to the mass ratio: take 20 parts of nanopart...

Embodiment 2

[0032] The difference with Example 1 is:

[0033] 1) The fresh fruiting body of Cordyceps militaris was processed by vacuum freeze-drying. The parameters of vacuum freeze-drying were: pre-cooling temperature -40°C, vacuum degree 12Pa, drying time 4 hours, and dried Cordyceps militaris was made.

[0034] 2) Take the dry product of Cordyceps militaris in step 1) and perform nano-grinding into particles with a particle size of about 450 nanometers. In this step, when performing nano-grinding, keep the temperature of the material in the tank at 15°C.

[0035] 3) According to the mass ratio: take 25 parts of nanoparticles prepared in step 2); crystalline fructose: 50 parts; β-cyclodextrin: 24.8 parts; citric acid: 0.4 parts and malic acid: 0.8 parts, and mix them.

[0036] 4) The nanoparticles prepared in step 2) are granulated in a fluidized bed. Drinking water is used as the binder in the fluidized bed granulation. The maximum pressure is 3Mpa, the liquid supply flow rate is 25 ...

Embodiment 3

[0038] The difference with Example 1 is:

[0039] 1) Fresh fruiting bodies of Cordyceps militaris were taken and subjected to vacuum freeze-drying. The parameters of vacuum freeze-drying were: pre-cooling temperature -40°C, vacuum degree 11Pa, drying time 5 hours, and dried Cordyceps militaris was made.

[0040] 2) Take the dry product of Cordyceps militaris in step 1) and perform nano-grinding into particles with a particle size of about 260 nanometers. In this step, when performing nano-grinding, keep the temperature of the material in the tank at 13°C.

[0041] 3) According to the mass ratio: take the nanoparticles prepared in step 2), and make the finished product through fluidized bed granulation. Drinking water is used as the binder for fluidized bed granulation. The atomization pressure is 2Mpa, the secondary atomization pressure is 3Mpa, the liquid supply flow rate is 25ml / min, and the liquid is supplied intermittently according to the input amount of solid raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com