Swirling flow type screen filtering system and filtering method of swirling flow type screen filtering system

A screen filtration and whirlpool technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of complicated installation and maintenance, consumption of large amounts of water, expensive equipment, etc., to achieve convenient maintenance, reduce investment costs and operation. The effect of cost, investment and operating cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

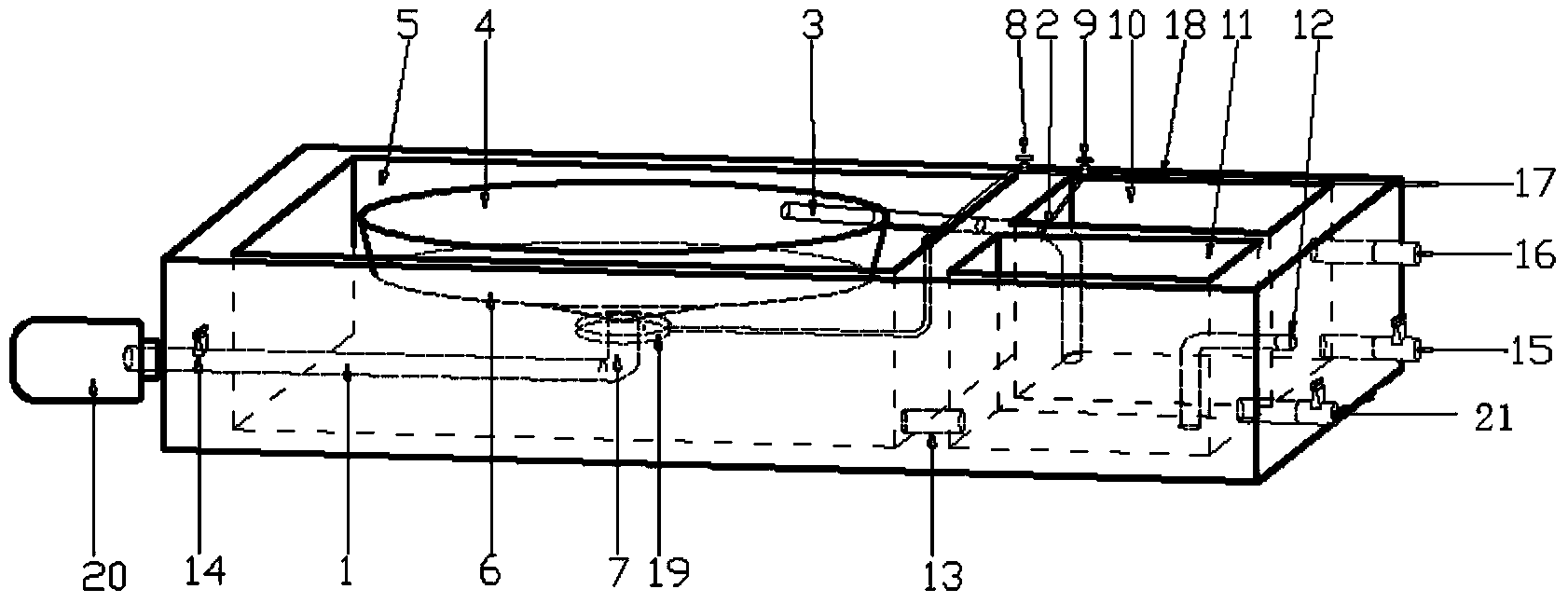

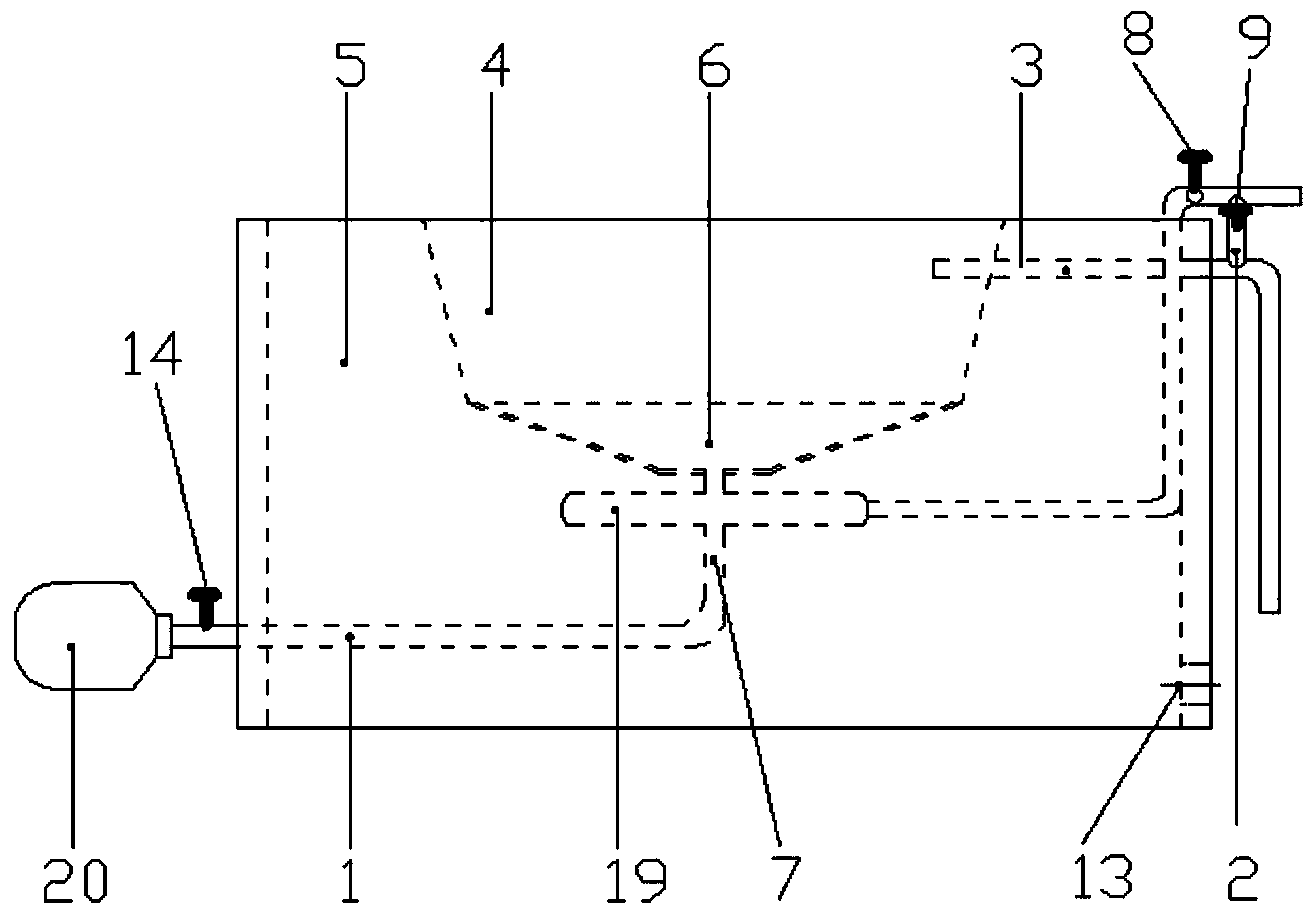

[0028] Such as figure 2 , a swirl type screen filter device, comprising a first water storage tank 5, a filter screen 4, a sewage collection screen 6, a sewage collection pipe 7, a sewage discharge pipe 1 and a concentration bag 20, and the filter screen 4 is located in the collection The upper part of the sewage screen 6, the two ends of the sewage collection pipe 7 communicate with the sewage collection screen 6 and the sewage pipe 1 respectively, the other end of the sewage pipe 1 communicates with the concentration bag 20, the filter screen 4, the sewage collection The screen 6, the sewage collection pipe 7 and the sewage discharge pipe 1 are located inside the first water storage tank 5, the concentration bag 20 is located outside the first water storage tank 5, and the bottom of the sewage collection screen 6 is provided with an aeration device, so A first water outlet pipe 13 is provided at the lower part of the first water storage tank 5 . The filtering screen 4 is i...

Embodiment 2

[0031] It is basically the same as in Example 1, except that the filter screen 4, the dirt collection screen 6 and the concentration bag 20 use nylon screen silk. The filter screen 4 is divided into upper and lower parts, the mesh of the upper part is 50 mesh, and the mesh of the lower part is 100 mesh. The dirt-collecting screen 6 meshes are 120 meshes, and the meshes of the concentration bag 20 are 200 meshes.

Embodiment 3

[0033] It is basically the same as Embodiment 1, except that the filter screen 4 is divided into upper and lower parts, the mesh of the upper part is 30 mesh, and the mesh of the lower part is 65 mesh. The dirt-collecting screen 6 meshes are 80 meshes, and the meshes of the concentration bag 20 are 130 meshes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com