Method for manufacturing flexible mesh heating wires and product

A production method and heating wire technology, which are applied to electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of inconvenient storage and carrying, poor comfort, poor flexibility, etc., and are conducive to wide popularization and application, and the production process is simple , the effect of good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

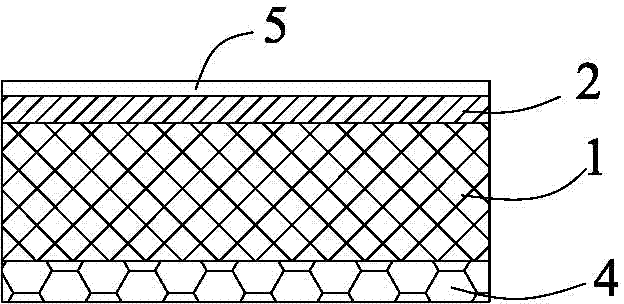

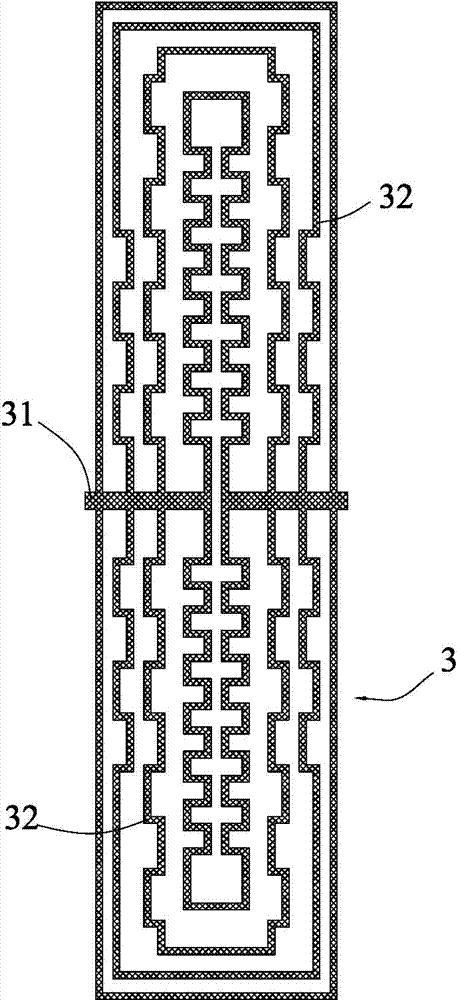

[0028] Embodiment 1: see figure 1 and figure 2 , a method for manufacturing a flexible mesh heating wire provided by an embodiment of the present invention, which includes the following steps.

[0029] (1) Prepare a flexible sheet carrier 1 .

[0030] (2) Prepare the silver ion paste 2, apply and print the silver ion paste 2 on the surface of the flexible sheet carrier 1 according to the pre-designed heating wire circuit shape trajectory, and leave the flexible sheet carrier 1 uncoated after curing The blank part printed with silver ion paste 2 is cut off, and after the cutting is completed, a silver ion heating circuit 3 consistent with the shape track of the pre-designed heating wire circuit is obtained, and the silver ion heating circuit 3 has two terminals 31, A plurality of curvilinear heating wire loops 32 are integrally connected in parallel between the two terminals 31 .

[0031] Detecting the resistance value of the silver ion heating circuit 3 solidified on the s...

Embodiment 2

[0045] Example 2: see image 3 , a flexible mesh heating wire manufacturing method and its products provided by the embodiment of the present invention are basically the same as in embodiment 1, the difference is that the step (2) is different and the weight percentage of each component of the silver ion paste is different , the specific differences are as follows.

[0046] (2) Prepare the silver ion paste 2, apply and print the silver ion paste 2 on the surface of the flexible sheet carrier 1, and after curing, apply and print the silver ion paste according to the pre-designed heating wire circuit shape track The flexible sheet carrier 1 of the material 2 is cut, and after the cutting is completed, a silver ion heating circuit 3 consistent with the shape track of the pre-designed heating wire circuit is obtained, and the silver ion heating circuit 3 has two terminals 31, A plurality of curvilinear heating wire loops 32 are integrally connected in parallel between the two ter...

Embodiment 3

[0048] Embodiment 3: A kind of flexible mesh heating wire manufacturing method and its products provided by the embodiment of the present invention are basically the same as Embodiment 1, one of the differences is that the weight percentages of the components of the silver ion paste 2 are different , each component and percentage by weight of this silver ion paste 2 are as follows: silver powder 75%, bisphenol A type epoxy resin 5%, acid anhydride curing agent 5%, methyl imidazole 2%, diethylene glycol butyl ether acetic acid 9% ester, 2% reactive diluent, 1.2% tetraethyl titanate, 0.8% polyamide wax.

[0049] The second difference is that, see Figure 4 , The silver ion heating circuit 3 has two terminals 31, and a plurality of linear heating wire circuits 32 are integrally connected in parallel between the two terminals 31.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com