Direct-current side harmonic suppression system and method for multi-pulse wave thyristor controllable rectification system

A rectification system and harmonic suppression technology, applied in the direction of converting AC power input to DC power output, output power conversion devices, electrical components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

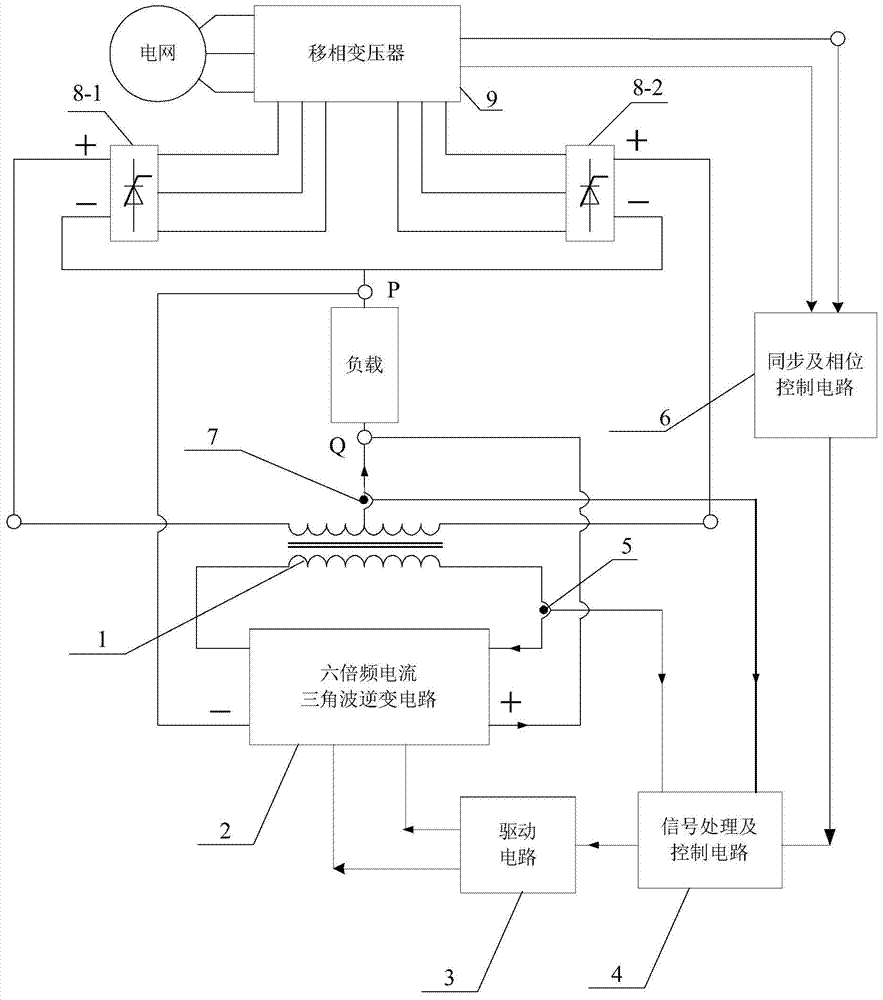

[0040] Specific implementation mode 1: see figure 1 This embodiment is described. The DC side harmonic suppression system of the multi-pulse thyristor controllable rectifier system described in this embodiment includes a first controllable rectifier bridge 8-1, a second controllable rectifier bridge 8-2 and a shifter Phase transformer 9, which also includes balanced reactor 1 with secondary side, six times frequency current triangular wave inverter circuit 2, signal processing and control circuit 4, drive circuit 3, secondary side current sensor 5, load loop current sensor 7 and synchronization and phase control circuit 6;

[0041] The three-phase input terminal of the phase-shifting transformer 9 is connected to the power grid, the first three-phase output terminal of the phase-shifting transformer 9 is connected to the three-phase input terminal of the first controllable rectifier bridge 8-1, and the The second three-phase output terminal of the phase-shifting transformer 9...

specific Embodiment approach 2

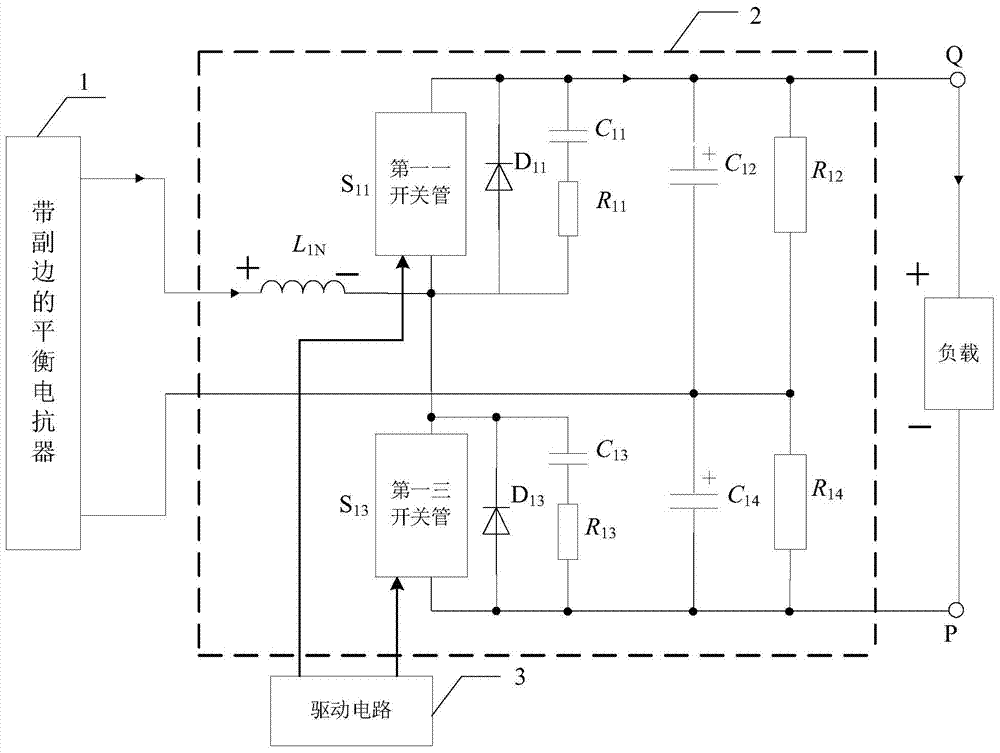

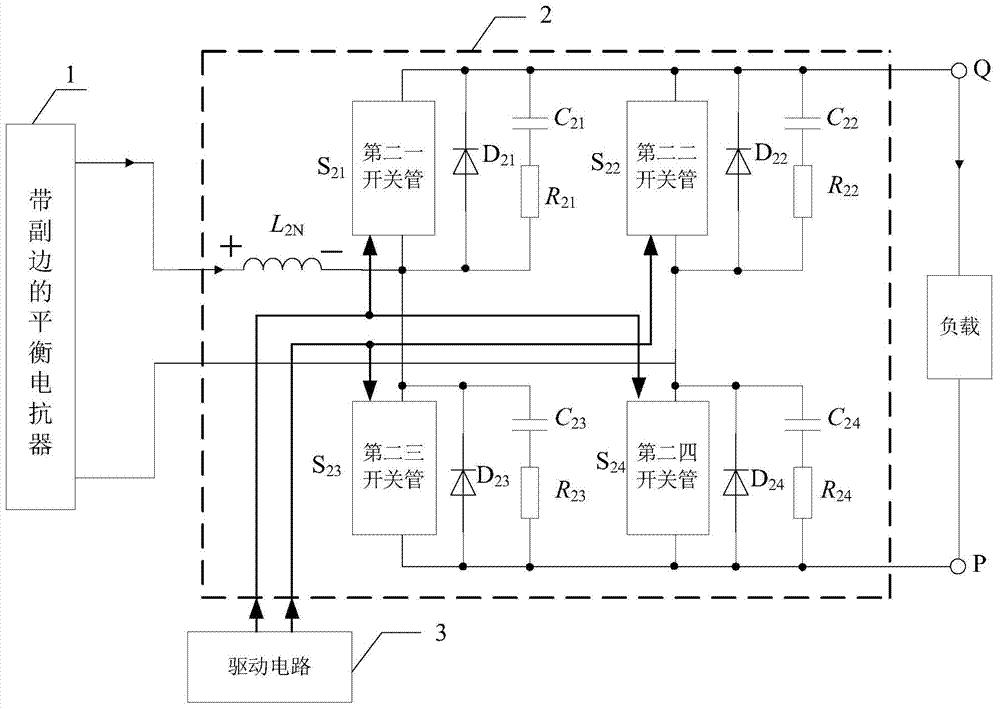

[0048] Specific implementation two: see figure 1 and 2 Describing this embodiment, the difference between this embodiment and the DC side harmonic suppression system of the multi-pulse thyristor controllable rectifier system described in the specific embodiment 1 is that the said sixfold frequency current triangular wave inverter circuit 2 is a half bridge structured circuit.

specific Embodiment approach 3

[0049] Specific implementation mode three: see figure 2 Describing this embodiment, the difference between this embodiment and the DC side harmonic suppression system of the multi-pulse thyristor controllable rectification system described in the second embodiment is that the sixfold frequency current triangular wave inverter circuit 2 includes a first inductor L 1N , the first switch tube S 11 , the first diode D 11 , the first capacitor C 11 , the first resistance R 11 , the first three switches S 13 , the first three diodes D 13 , the first three capacitors C 13 , the first three resistors R 13 , the first and second capacitors C 12 , the first and second resistors R 12 , the first four capacitors C 14 and the first four resistors R 14 ,

[0050] The first inductance L 1N One end of L is connected to one end of the secondary winding of the balanced reactor 1 with the secondary side as the first current input end of the six-fold frequency current triangular wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com