Inverted bottom-emitting organic electroluminescence device and manufacturing method thereof

A luminescence and bottom emission technology, which is applied in the manufacture of organic semiconductor devices, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of exciton loss, difficulty in evaporation temperature, and low rate increase, and achieve enhanced luminous intensity , Improve luminous efficiency, enhance the effect of light scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

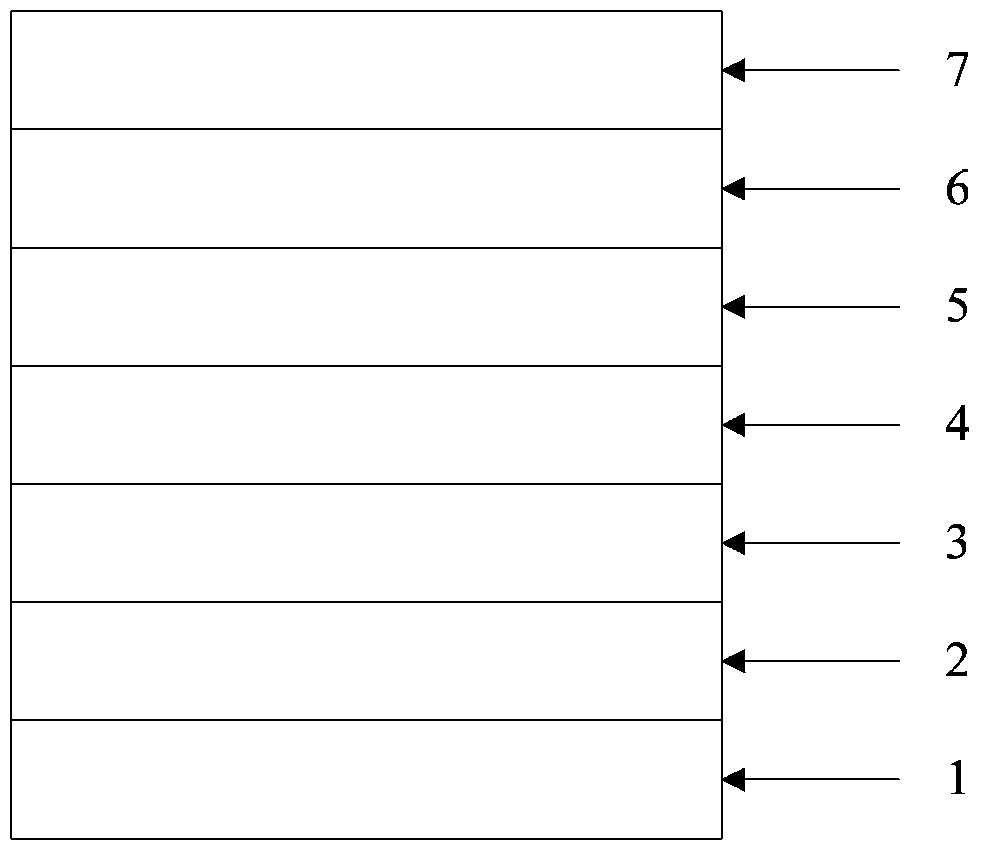

preparation example Construction

[0032] The preparation method of the above-mentioned inverted bottom emission organic electroluminescent device comprises the following steps:

[0033]S1. First, carry out photolithography treatment on the cathode substrate, cut it into the required size, and then clean the cathode substrate, that is, use detergent, deionized water, acetone, ethanol, and isopropanol to ultrasonically for 15 minutes each to remove the surface of the cathode substrate. Organic Pollutants;

[0034] S2. Coating an acetic acid compound solution with a mass concentration of 1 to 30% on the surface of the conductive cathode layer of the cathode base, and drying to obtain an auxiliary electron transport layer with a thickness of 10 to 20 nm; wherein, the material of the auxiliary electron transport layer is Acetic compounds such as zinc acetate (ZnAc), calcium acetate (CaAc) or magnesium acetate (MgAc);

[0035] S3, sequentially stacking and vapor-depositing an electron transport layer, a light-emitt...

Embodiment 1

[0042] First, the ITO glass is subjected to photolithography treatment, cut into the required size, and the organic pollutants on the surface of the ITO glass are removed with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes each;

[0043] Then, spin-coat the auxiliary electron transport layer: first, ZnO is added to acetic acid, and Zn(Ac) with a mass concentration of 5% is configured. 2 solution; secondly, the Zn(Ac) 2 The solution was spin-coated on the surface of the ITO layer of ITO glass to control the thickness to 100nm, and then dried at 100°C to obtain Zn(Ac) 2 The auxiliary electron transport layer of the material;

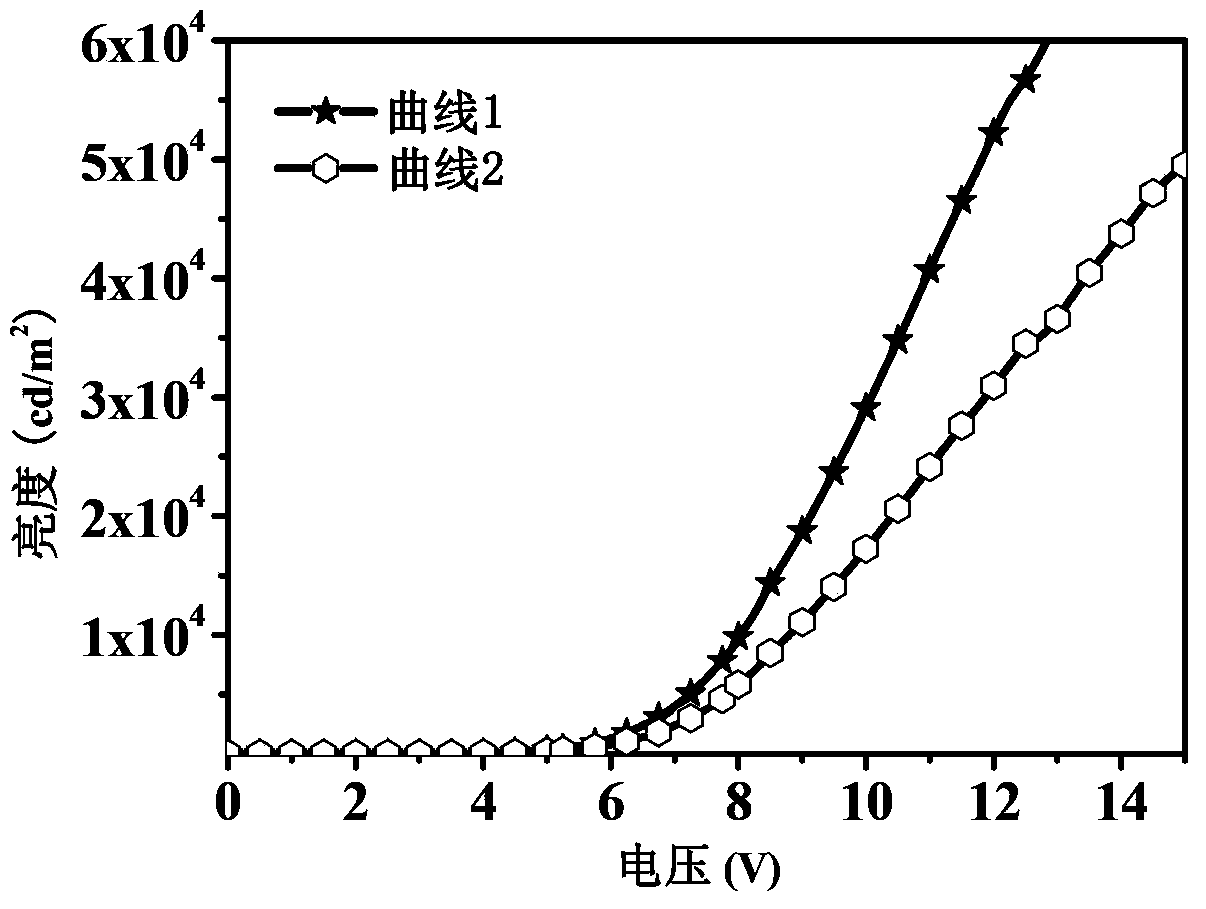

[0044] Next, on the surface of the auxiliary electron transport layer, the vapor-deposited electron transport layer, light-emitting layer, hole transport layer, hole injection layer and anode layer are stacked in sequence; the materials are: Bphen, TCTA:Ir(ppy) 3 (Represents Ir(ppy) 3 As a guest material doped into TCTA hos...

Embodiment 2

[0047] First, the IZO glass is photolithographically processed, cut into the required size, and then ultrasonicated for 15 minutes with detergent, deionized water, acetone, ethanol, and isopropanol to remove organic pollutants on the surface of the IZO glass;

[0048] Then, spin-coat the auxiliary electron transport layer: first add ZnO to acetic acid, and configure a Zn(Ac) with a mass concentration of 30%. 2 solution; secondly, the Zn(Ac) 2 The solution was spin-coated on the surface of the IZO layer of IZO glass to control the thickness to 200nm, and then dried at 100°C to obtain Zn(Ac) 2 The auxiliary electron transport layer of the material;

[0049] Next, on the surface of the auxiliary electron transport layer, the vapor-deposited electron transport layer (the material is TPBi with a thickness of 80nm), the light-emitting layer (the material is Ir(MDQ) 2 (acac) is doped into the NPB host material as a guest material, expressed as NPB:Ir(MDQ) 2 (acac), Ir(MDQ) 2 (aca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com