Method for manufacturing packaging product with metalized side wall

A production method and metallization technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of reducing the number of packaging substrate units, increasing the cost of production tools, increasing product quality risks, etc., and achieving packaging The effect of increasing the number of substrate units, improving work efficiency, reducing process complexity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

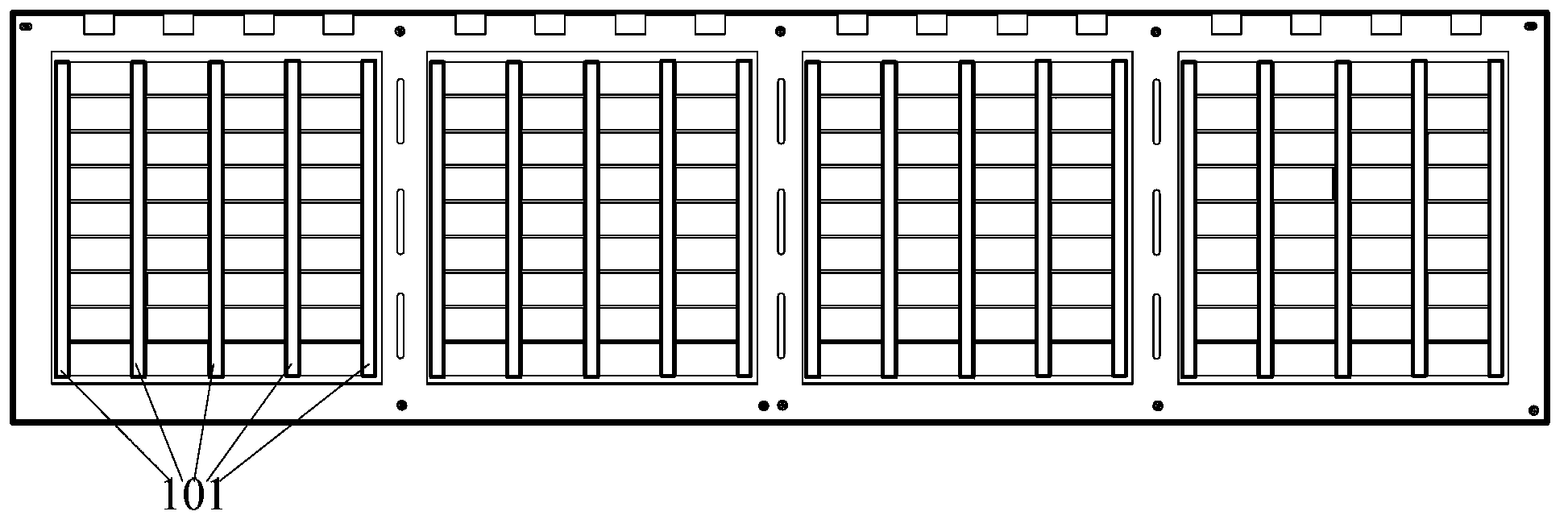

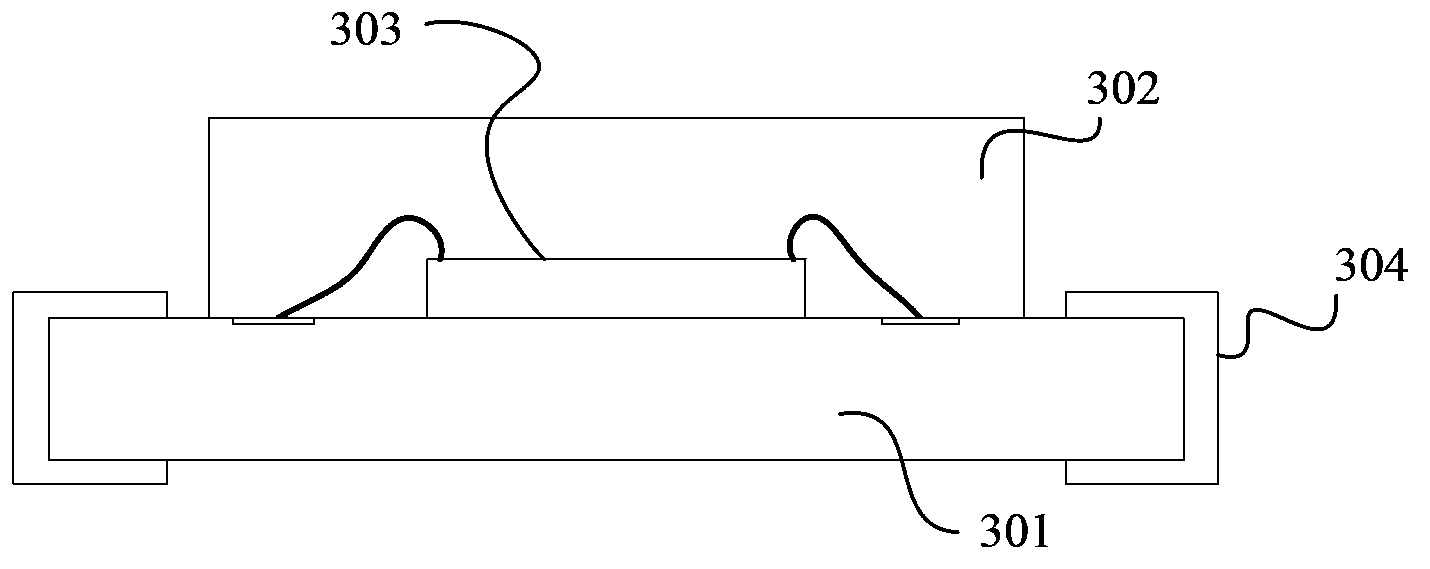

[0028] Before implementing the manufacturing method of a sidewall metallization packaging product according to the embodiment of the present invention, the following substrate structure is obtained through conventional substrate manufacturing and packaging processing: Figure 4 As shown, the substrate is composed of several packaging substrate units 401 , and circuits 402 are provided on the front and back sides of the packaging substrate units 401 .

[0029] Such as Figure 5 As shown, the manufacturing method of the above-mentioned sidewall metallization packaging product is mainly based on the above-mentioned substrate, and includes the following process flow:

[0030] 501 , make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com