Photosensitive resin composition, colored filter, liquid crystal display device and imaging element

A photosensitive resin and composition technology, applied in optical components, instruments, optics, etc., can solve the problems of insufficient sensitivity, slow development speed, pattern peeling, etc., and achieve excellent sensitivity and adhesion, excellent transmittance and contrast ratio. , Excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

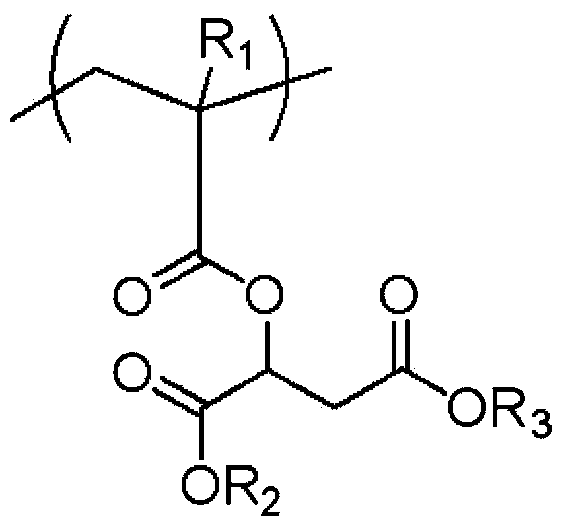

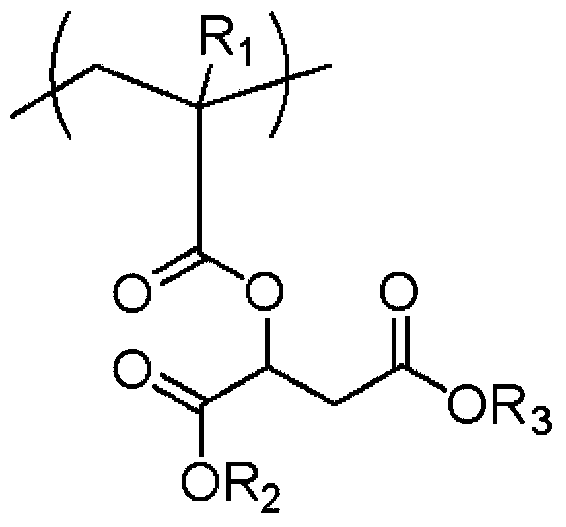

[0155] Synthesis Example 1: Synthesis of Compound M-1

[0156] a) Synthesis of M-1a compound

[0157] Put 50.0 parts by weight of di-tert-butyl-2-hydroxysuccinate (di-tert-butyl-2-hydroxysuccinate), 24.65 parts by weight of triethylamine, and 300.0 parts by weight of tetrahydrofuran into a four-neck round bottom flask equipped with a cooling tube and a stirrer. parts by weight, while stirring, the internal temperature of the reactor was cooled to 0°C. Next, 25.46 parts by weight of methacryloyl chloride was dropped over 30 minutes. After the dropwise addition, the reaction temperature was raised to room temperature. Then, the reaction was continued for 5 hours. After completion of the reaction, 150 parts by weight of a saturated aqueous sodium bicarbonate solution was added to the reaction liquid, and then 200 parts by weight of ethyl acetate was added for extraction. The aforementioned extract was washed with 150 parts by weight of saturated brine, dried over anhydrous ma...

Synthetic example 2

[0163] Synthesis Example 2: Synthesis of Alkali-Soluble Resin

[0164] 120 parts by weight of propylene glycol monomethyl ether acetate, 80 parts by weight of propylene glycol monomethyl ether, 2 parts by weight of AIBN, 20.0 parts by weight of the aforementioned M-1 compound, 60.0 parts by weight of 4-methylstyrene, 10 parts by weight of benzyl methacrylate, 10 parts by weight of methyl methacrylate, 3 parts by weight of n-dodecyl mercaptan, the atmosphere of the flask was replaced with nitrogen . Then, stirring was performed, and the temperature of the reaction liquid was raised to 80° C., followed by reaction for 8 hours. The acid value of the solid content of the alkali-soluble resin synthesized in this way was 99.2 mgKOH / g, and the weight average molecular weight Mw measured by GPC was about 9200.

Synthetic example 3

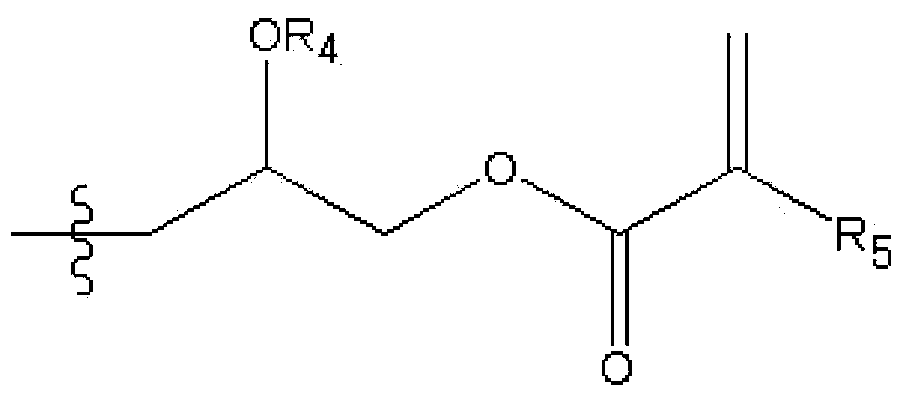

[0165] Synthesis Example 3: Synthesis of Alkali-Soluble Resin

[0166] 120 parts by weight of propylene glycol monomethyl ether acetate, 80 parts by weight of propylene glycol monomethyl ether, 2 parts by weight of AIBN, 20.0 parts by weight of the aforementioned M-1 compound, 50.0 parts by weight of 4-methylstyrene, 10 parts by weight of benzyl methacrylate, 10 parts by weight of methyl methacrylate, 3 parts by weight of n-dodecyl mercaptan, the atmosphere of the flask was replaced with nitrogen . Then, stirring was performed, and the temperature of the reaction liquid was raised to 80° C., followed by reaction for 8 hours. Afterwards, the temperature of the reaction solution is down to normal temperature, after the flask atmosphere is replaced by nitrogen into air, drop into 0.2 parts by weight of triethylamine, 0.1 parts by weight of 4-methoxyphenol, 10.0 parts by weight of glycidyl methacrylate, at 100 °C for 6 hours. The acid value of the solid content of the alkali-so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com