Phase shift mask blanks and photomasks for flat panel displays

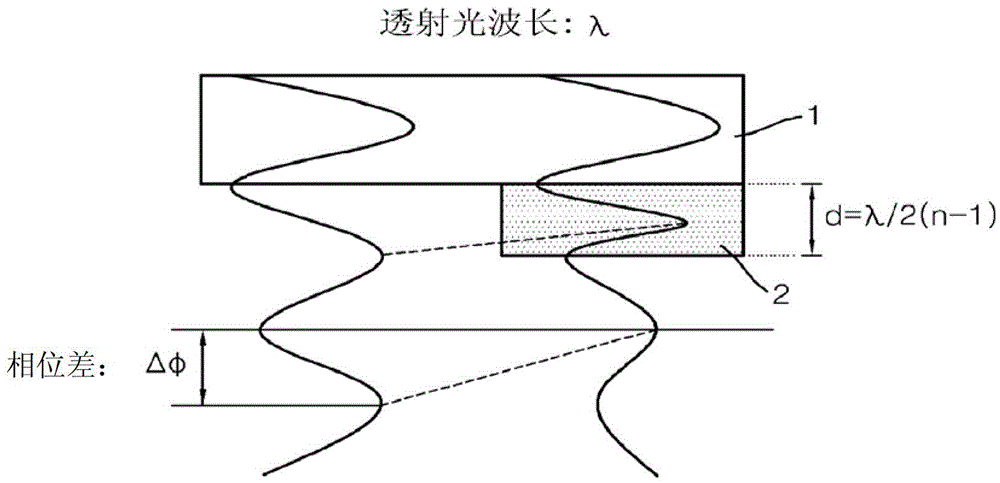

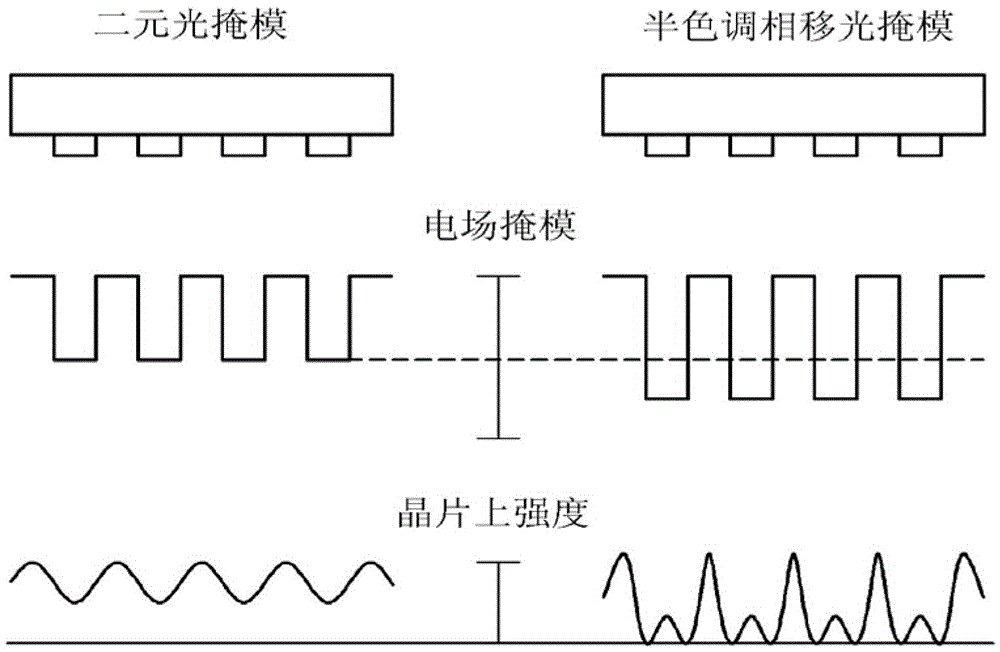

A flat-panel display and phase-shift mask technology, applied in the field of phase-shift mask blanks and photomasks, can solve the problems of obstructing fine patterns, unclear boundary of the phase-shift layer, affecting the uniformity of the phase-shift layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

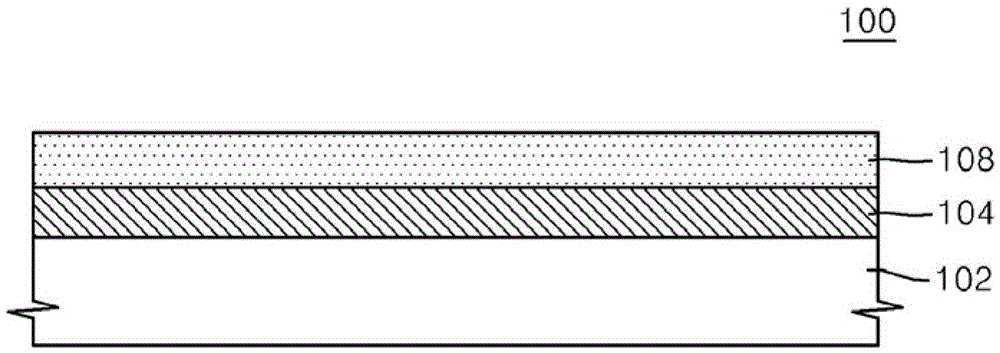

[0072] Phase shift layer formation

[0073] In order to evaluate a phase shift mask blank according to an exemplary embodiment of the present invention, a multi-layer type phase shift layer was formed on a transparent substrate.

[0074] Specifically, a chromium (Cr) target is used as a sputtering target to form the phase shift layer by means of a sputtering process. In this case, the sputtering process is performed using at least one of the following gases: argon (Ar), nitrogen (N 2 ), carbon dioxide (CO 2 ), methane (CH 4 ), and nitric oxide (NO), and the phase shift layer is formed as a CrCON layer with a thickness of about

[0075] [Table 1]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com