Multilayer-film filling type composite medium nanometer period grating structure and manufacturing method of multilayer-film filling type composite medium nanometer period grating structure

A composite medium and grating structure technology, applied in diffraction grating, opto-mechanical equipment, optics, etc., can solve the problem of large absorption of incident waves, improve surface flatness, improve etching morphology, accurately control etching rate and The effect of etch depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is not limited by the following embodiments, and specific embodiments can be determined according to the technical solutions of the above inventions and actual conditions.

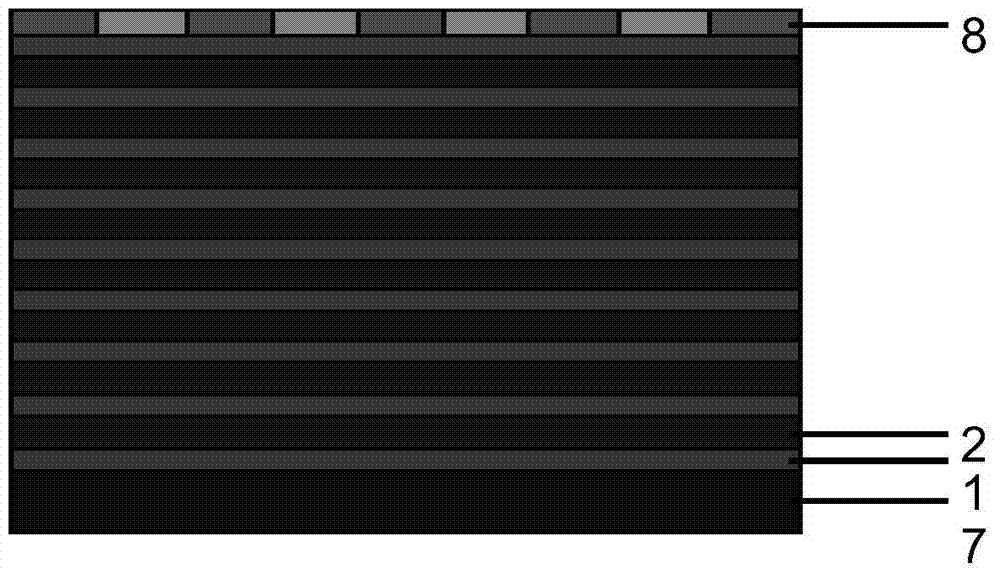

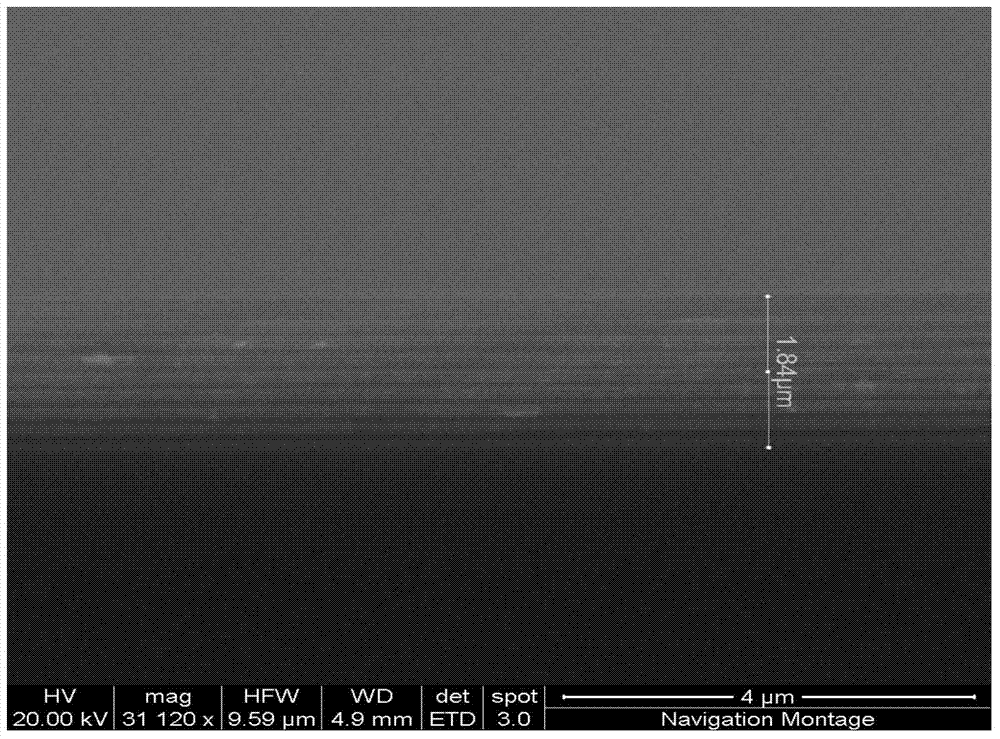

[0025] The duty ratio of the filled sub-wavelength nano-period guided mode resonant dielectric grating of the present invention is 1:1, such as figure 1 As shown, the grating is composed of two dielectric materials with different refractive indices. The selection of these two dielectric materials and the grating period are mainly determined by factors such as the size of the resonance wavelength, the size of the resonance peak and its half-width, and the width of the cut-off frequency of the resonance peak. . What is combined with the grating is a one-dimensional periodic multilayer film structure composed of two different dielectric materials alternately. Corresponding to the above grating structure, when the spectral high reflection condition in a specific frequency range is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com