Method for measuring components of nickel-based high-temperature alloy steel by using photoelectric direct reading spectrometer

A high-temperature alloy steel, photoelectric direct reading technology, applied in the field of metallurgical analysis, can solve the problems of high cost, long cycle, complicated analysis steps, etc., and achieve the effect of reducing analysis cost, shortening analysis period, and simplifying analysis procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

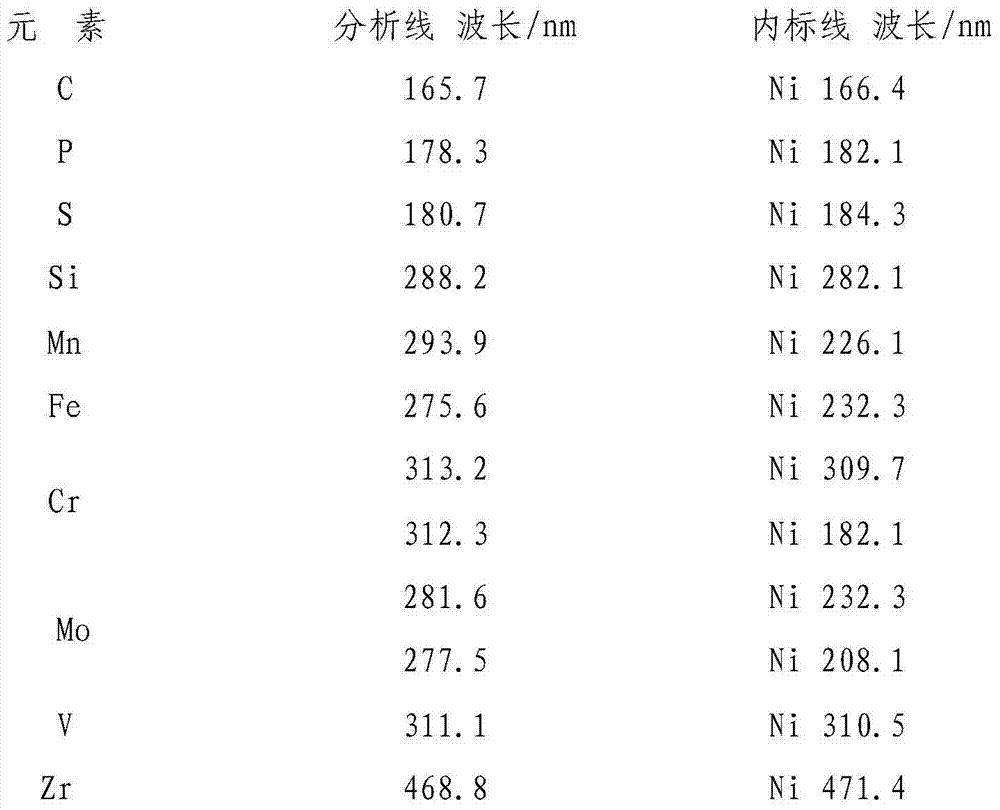

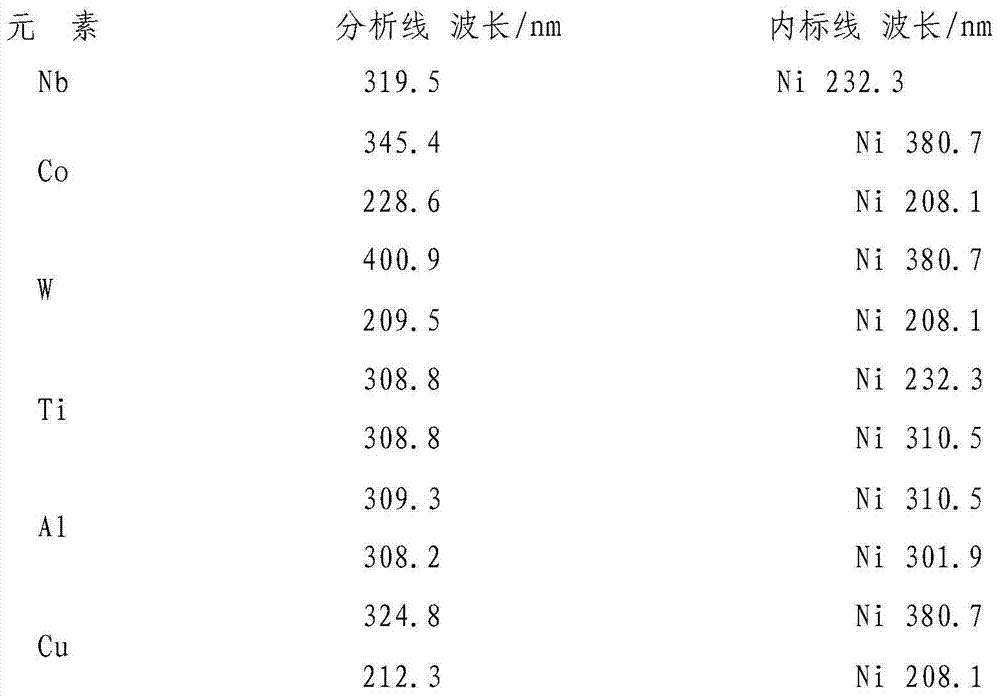

[0031] 1 Determine the analysis conditions as follows:

[0032]

[0033]

[0034]

[0035] 2. Preparation of type standardized samples and analysis samples: use nickel-based high-temperature alloy steel to manufacture analysis samples, type standardized samples are obtained from daily production analysis, and the smelting and rolling process is basically the same as the analysis sample material, with accurate chemical composition inside Sample. The surface roughness of the analysis surface of the analysis sample is less than 0.8;

[0036] 3. Make a calibration curve: Under the selected working conditions, excite the standard sample of the photoelectric direct reading spectrometer, and each sample is excited at least 3 times, take the average value of the relative intensity of each element to be measured as the ordinate, and take the standard sample The concentration value of this element draws a calibration curve on the abscissa;

[0037] 4. Analysis type standard s...

Embodiment 2

[0040] 1 Determine the analysis conditions as follows:

[0041]

[0042]

[0043]

[0044]

[0045] 2 Preparation of type standardized samples and analysis samples: Nickel-based high-temperature alloy steel is used to manufacture analysis samples. Type standardized samples are obtained from daily production analysis. The smelting and rolling process is basically the same as the analysis sample material, and there are accurate internal standards for chemical composition. Sample. The surface roughness of the analysis surface of the analysis sample is less than 0.8;

[0046] 3 Make a calibration curve: Under the selected working conditions, excite the standard sample of the photoelectric direct reading spectrometer, each sample is excited at least 3 times, take the average value of the relative intensity of each element to be measured as the ordinate, and take the standard sample in the standard sample The concentration value of the element draws a calibration curve ...

Embodiment 3

[0050] 1 Determine the analysis conditions as follows:

[0051]

[0052]

[0053]

[0054]

[0055] 2. Preparation of type standardized samples and analysis samples: use nickel-based high-temperature alloy steel to manufacture analysis samples, type standardized samples are obtained from daily production analysis, and the smelting and rolling process is basically the same as the analysis sample material, with accurate chemical composition inside Sample. The surface roughness of the analysis surface of the analysis sample is less than 0.8;

[0056] 3. Make a calibration curve: Under the selected working conditions, excite the standard sample of the photoelectric direct reading spectrometer, and each sample is excited at least 3 times, take the average value of the relative intensity of each element to be measured as the ordinate, and take the standard sample The concentration value of this element draws a calibration curve on the abscissa;

[0057] 4. Analysis typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com