Carbon reducing, sulfur reducing, iron removing and iron ore concentrate recovering method for coal ash

A technology for fly ash and iron recovery, applied in the field of solid waste resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

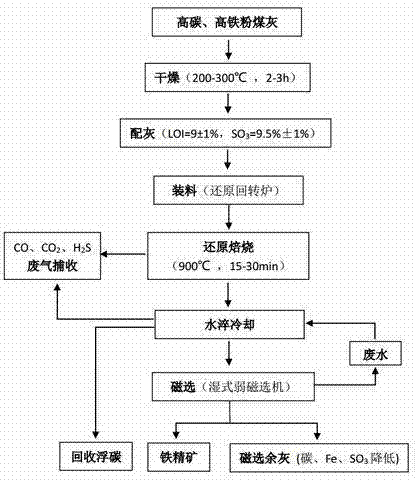

Method used

Image

Examples

Embodiment 1

[0026] (1) Loss on ignition 9.0%, SO 3 The content of 9.6% fluidized bed boiler electrostatic precipitator fly ash was reduced and roasted at 900°C for 15 minutes.

[0027] (2) Quickly pour the fly ash after reduction and roasting into the water quenching tank for water quenching cooling. The bottom of the water quenching tank is provided with a fly ash slurry discharge valve, and the water quenching tank is equipped with a stirrer to break up the sintered lumps ; The notch is provided with a fishing net or a scraper to collect floating carbon on the water surface.

[0028] (3) Use a wet weak magnetic separator to magnetically separate iron concentrate from the fly ash slurry cooled by water quenching, with a magnetic field strength of 170mT. The iron concentrate and tailings are subjected to suction filtration and drying respectively to obtain iron concentrate and magnetic separation ash.

[0029] (4) The iron ore concentrate with a yield of 8.3% and a TFe grade of 52.9% wa...

Embodiment 2

[0031] (1) The fly ash of the fluidized bed boiler electrostatic precipitator with 9.0% loss on ignition and 9.6% SO3 content was reduced and roasted at 900°C for 30 minutes.

[0032] (2) Same as step (2) of Example 1.

[0033] (3) Same as step (3) of Example 1.

[0034](4) The iron ore concentrate with a yield of 8.9% and a TFe grade of 47.9% was finally obtained, and the recovery rate of total iron was 48.6%. 3 content dropped to 0.34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss on ignition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com