Preparation method for high performance acrylic waterborne resin

An acrylic water-based, high-performance technology, applied in the direction of coating, can solve problems such as low cost, achieve stable product performance, good production stability, and solve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of preparation method of high-performance acrylic water-based resin is characterized in that comprising the steps:

[0022] 1) Grinding the solid acrylic resin into the fine powder that the 120-mesh sieve passes through, and set aside;

[0023] 2) In a stainless steel container, under mechanical stirring, add in order:

[0024] Water: 5%

[0025] Ethanol: 28%

[0026] Ethylene glycol butyl ether: 11%

[0027] Ammonia: 5%

[0028] Defoamer: 1%;

[0029] 3) Under mechanical stirring, slowly add 50% of solid acrylic powder resin to make it fully dispersed to a transparent viscous resin liquid, and pack it in a large barrel for paint making.

Embodiment 2

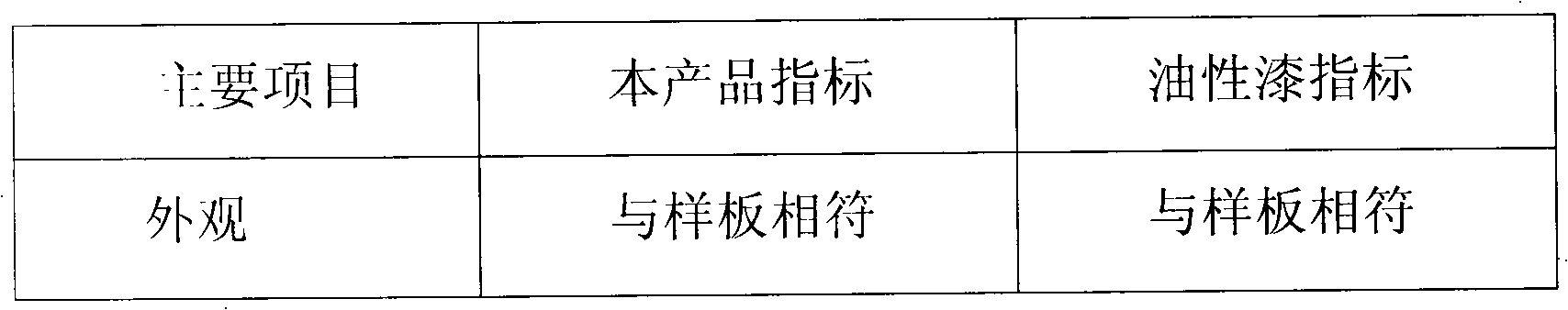

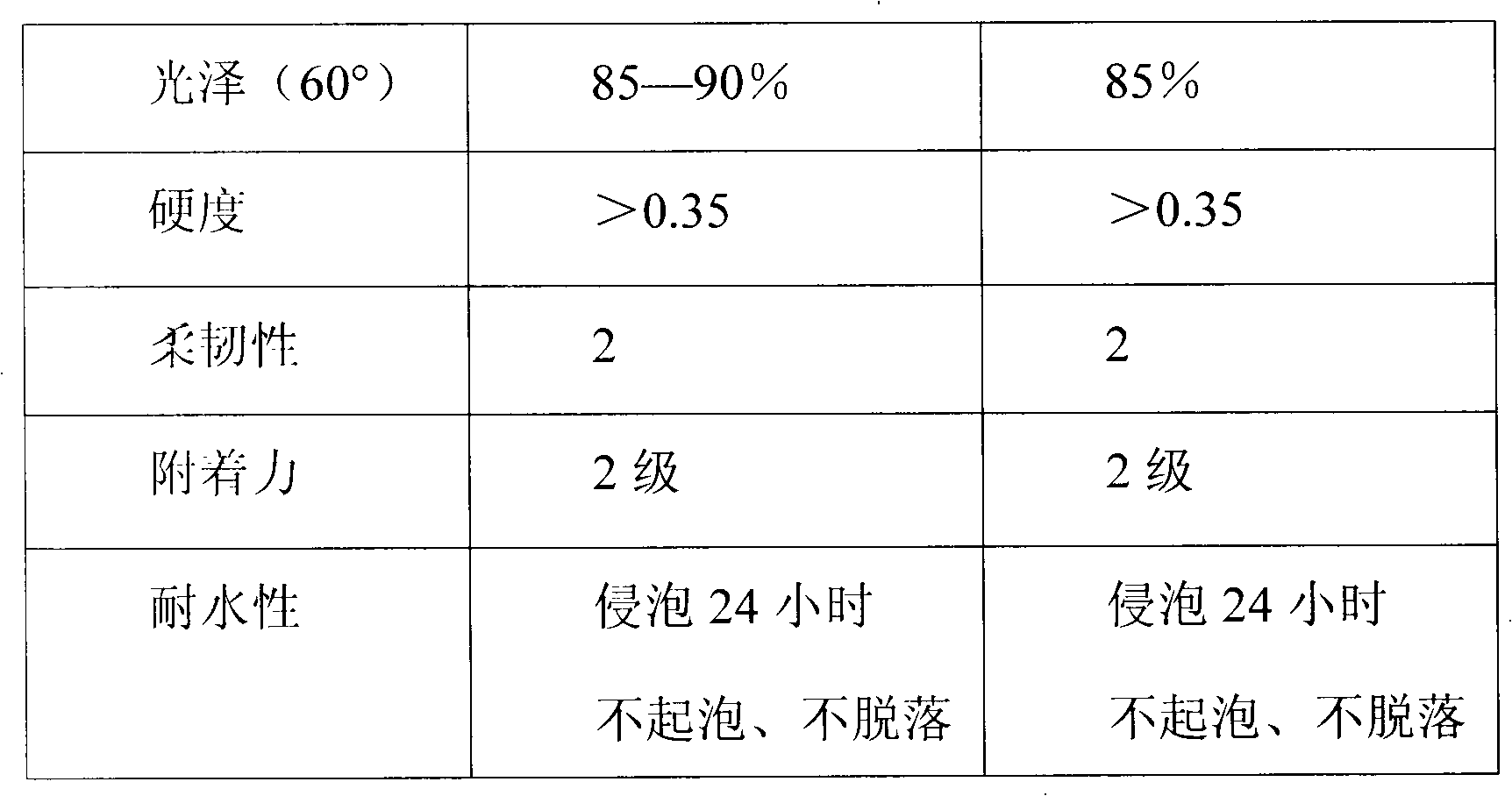

[0031] Adopt acrylic resin of the present invention to make water-based paint and the main performance contrast of equivalent oil-based paint

[0032] Table 1 Main performance comparison

[0033]

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com