A composition, its functional film and preparation method

A composition and film technology, applied in the field of polymers, can solve problems such as poor moisture permeability, rising air humidity, and unsatisfactory anti-fog effects, and achieve good anti-fog and powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

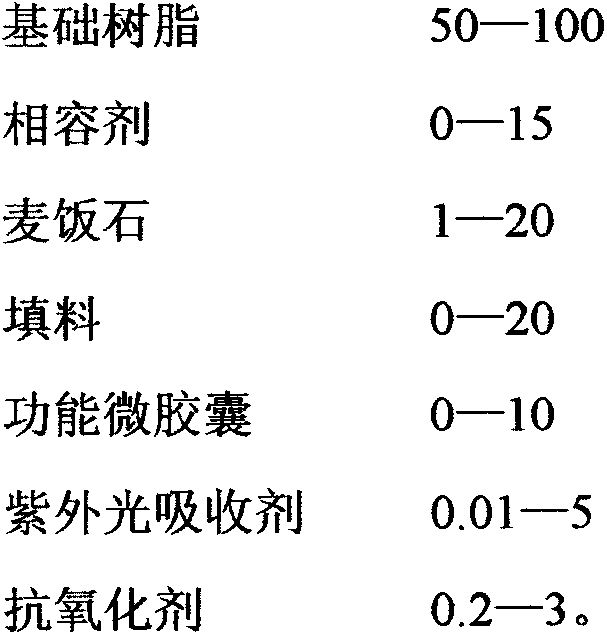

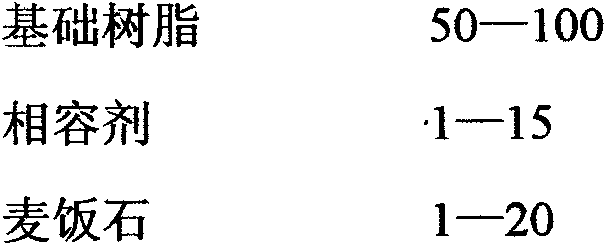

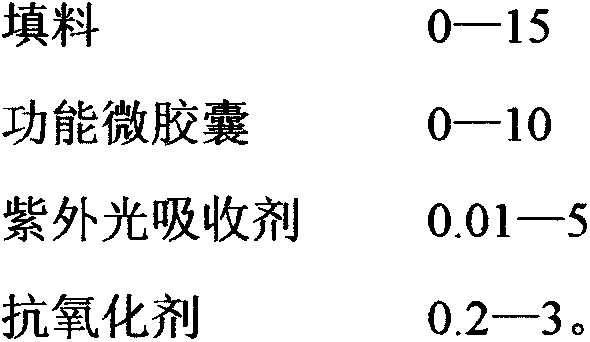

Method used

Image

Examples

Embodiment 1

[0039] 50 parts of HDPE, 1 part of 80-mesh medical stone powder, 0.01 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.2 part of 1,1,3- Tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane and 0.1 part of mold release agent are extruded and granulated through an extruder, and the obtained granules are blown to prepare a single-layer functional film.

[0040] The obtained sample was tested, and the absorbance was 0.122, it was fogged after 4 seconds, and the conductivity was 3.1 μs / cm.

Embodiment 2

[0042] 60 parts of HDPE, 40 parts of PP, 20 parts of 80 parts of medical stone powder treated with silane coupling agent KH-550, 5 parts of bis(2,2,6,6-tetramethyl-4-piperidine Base) sebacate, 3 parts of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane are extruded and granulated through an extruder, and the resulting pellets are passed through a stream The single-layer functional film is stretched, and the obtained film is uniaxially stretched.

[0043] The obtained sample was tested, and the absorbance was 0.009. After 7 seconds of fogging, the conductivity was 17.7 μs / cm, and there was no insect repellent effect.

Embodiment 3

[0045] 80 parts of HDPE, 1 part of 100 mesh medical stone powder, 1 part of 80 mesh medical stone powder, 0.2 part of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate , 0.1 part of benzophenone, 0.2 part of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, 0.1 part of 2,2'-di-p-hydroxyphenylpropane , 0.1 part of release agent is extruded and granulated through an extruder, and the obtained pellets are extruded to obtain a single-layer functional film.

[0046] The obtained sample was tested, and the absorbance was 0.115, and the conductivity was 4.6 μs / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com