Flame-retardant modified silane coupling agent and preparation method thereof

A silane coupling agent and modification technology, applied in the field of flame retardants, can solve problems such as human hazards, achieve moderate reaction temperature, mild reaction conditions, and improve compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Put 50g of 2-methyl-2,5-dioxo-1,2-oxaphospholane (OP) and 200ml of n-heptane into a 250ml three-necked flask, which is equipped with a reflux condenser and a stirrer and a constant pressure dropping funnel, then add 5ml of triethylamine, raise the temperature to 95°C, add 80g of 3-aminopropyltriethoxysilane (KH550) into the constant pressure dropping funnel and slowly drop it while stirring, and react for 4h . The reaction mixture was taken out and left to cool, and the mother liquor was separated with a separatory funnel to obtain a viscous product in the lower layer, which was dried in a vacuum oven at 100°C for about 3 hours to obtain the final product, which was specifically γ-(3-(formazan Hydroxyphosphono)-propionamido)propyl triethoxysilane, R in this product is γ-(3-(methylhydroxyphosphono)-propionamido)propyl, that is, alkylene, referred to as P -KH550.

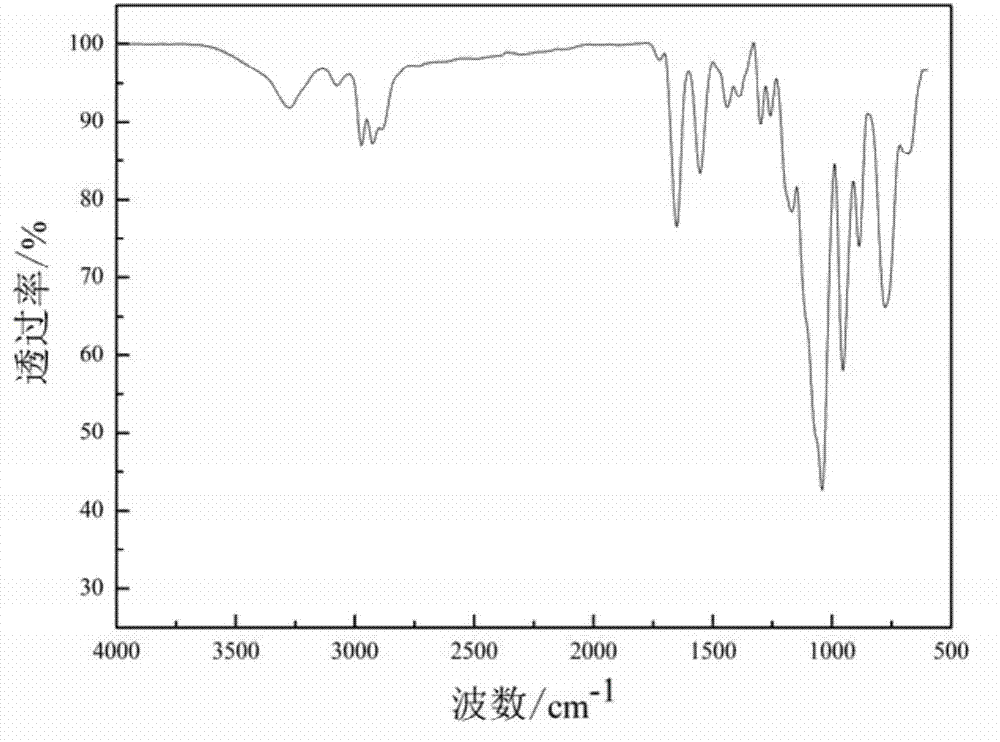

[0041] Use attenuated total reflection (Attenuated Total Reflection, ATR) to conduct infrared analysis on t...

Embodiment 2

[0044] Weigh 100 parts by mass of silicon dioxide (purity 99.0%, particle size 4.9 μm), 8 parts by mass of P-KH550 provided in Example 1 of the present invention, add them to 500 mL of ethanol, where ethanol is a dispersant, and then add 2 parts by mass Glacial acetic acid, dispersed under 700W ultrasonic conditions for 20min, and then refluxed at 80°C for 2h under the condition of strong stirring, after 2h, suction filtration and drying to obtain P-KH550 modified SiO 2 ; Replace P-KH550 with KH550, repeat the above experimental steps to obtain KH550 modified SiO 2 .

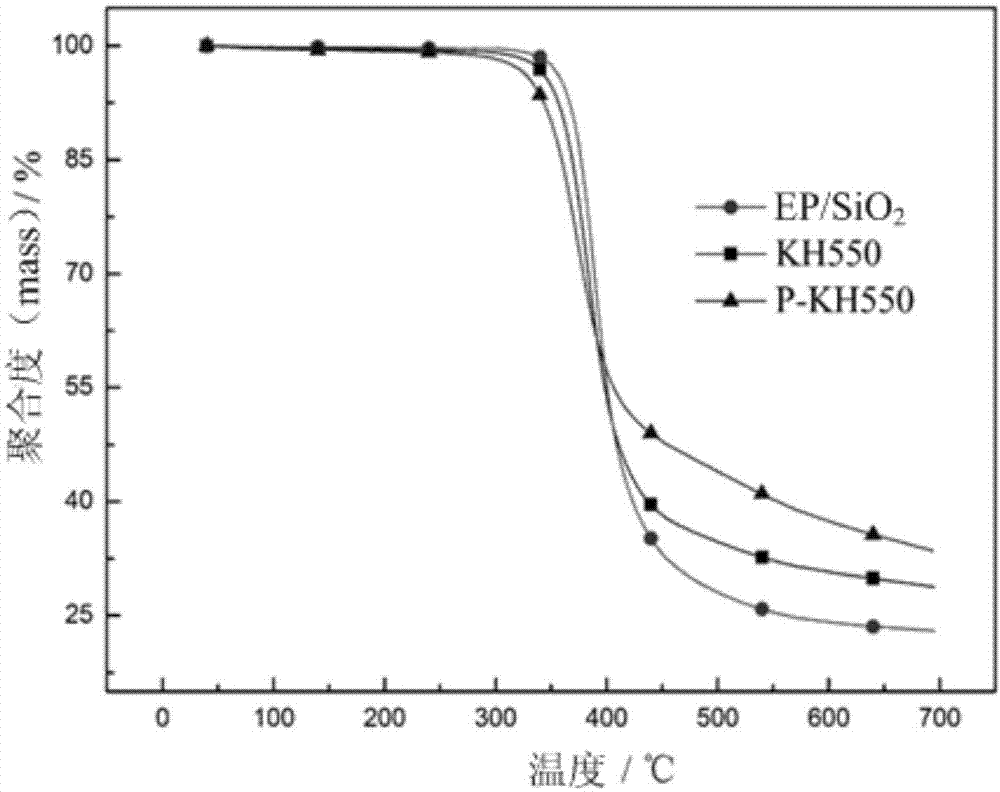

[0045] SiO without any treatment 2 , KH550 modified SiO 2 and P-KH550 modified SiO 2 Add 15 parts by mass to three epoxy resins (EP) of 100 parts by mass, and carry out the following experiments respectively. After dispersing and mixing with 700W ultrasonic waves at 90°C for 30 minutes, add 25 parts by mass of diaminodiphenylmethane to form Curing system, the system is cured under the process conditions of 1...

Embodiment 3

[0047] Add 50g of 2-methyl-2,5-dioxo-1,2-oxaphospholane and 120ml of cyclohexane into a 250ml three-necked flask equipped with a reflux condenser, a stirrer and a constant pressure dropping funnel , then add 10ml of tri-n-propylamine, raise the temperature to 20°C, add 97g of N-(2-aminoethyl)-3-aminopropyltriethoxysilane (KH7910) into the constant pressure dropping funnel and drop it slowly, at the same time Stirring, reaction 24h. The reaction mixture was taken out and left to cool, and the mother liquor was separated with a separatory funnel to obtain a viscous product in the lower layer, which was dried in a vacuum oven at 100°C for about 3 hours to obtain the final product, specifically N-(2-aminoethyl base)-3-(methylhydroxyphosphono)propionamido)propyltriethoxysilane (R in this product is N-(2-aminoethyl)-3-(methylhydroxyphosphono)propionamide Base) propyl, that is, R is a secondary aminoalkylene). It is called P-KH791 for short.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com