Mineral waste residue liquid composite grinding aid and preparation method thereof

A grinding aid and liquid technology, which is used in the preparation of slag liquid composite grinding aids and the field of slag liquid composite grinding aids, can solve the problems of rising prices, high prices of grinding aids, and restrictions on promotion and application, and achieve sufficient supply, Improve the powder particle distribution and morphology, and the effect of simple processing and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

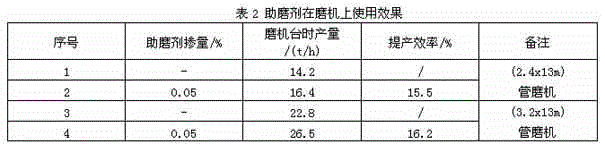

Examples

Embodiment 1

[0024] First, add 5 kg of sodium hexametaphosphate to 90 kg of water, heat and stir slightly, the temperature is 20 ° C, after it is completely dissolved, add 5 kg of sodium lauryl sulfate into the solution, continue heating, the temperature does not exceed 38°C, stirring and dissolving. Finally, 18 kg of trimixed alcohol, 7 kg of ethyl acetate and 8 kg of molasses were added to the solution, stirred evenly, and then cooled and filtered. The mixed alcohol is a mixture of two or three of industrial grade ethylene glycol, diethylene glycol and triethylene glycol.

Embodiment 2

[0026] First, add 2 kg of sodium hexametaphosphate to 95 kg of water, heat and stir slightly, the temperature is 20 ° C, after it is completely dissolved, add 2 kg of sodium lauryl sulfate into the solution, continue heating, the temperature does not exceed 38°C, stirring and dissolving. Finally, 17 kg of trimixed alcohol, 8 kg of ethyl acetate and 8 kg of molasses were added to the solution, stirred evenly, and then cooled and filtered. The mixed alcohol is a mixture of two or three of industrial grade ethylene glycol, diethylene glycol and triethylene glycol.

Embodiment 3

[0028] First, add 1 kg of sodium hexametaphosphate to 85 kg of water, heat and stir slightly, the temperature is 20°C, after it is completely dissolved, add 1 kg of sodium lauryl sulfate into the solution, continue heating, the temperature does not exceed 38°C, stirring and dissolving. Finally, 16 kilograms of trimixed alcohol, 6 kilograms of ethyl acetate and 6 kilograms of molasses were added into the solution and stirred evenly, and the mixture was cooled and filtered. The mixed alcohol is a mixture of two or three of industrial grade ethylene glycol, diethylene glycol and triethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com