Prebaked anode crude and cooked product breaking and adding system

A technology for pre-baked anodes and products, applied in the fields of solids crushing, adding systems, and screening, can solve the problems of output and quality impact, inability to add in proportion, and many equipment, etc., to achieve excellent product quality, reduce investment, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

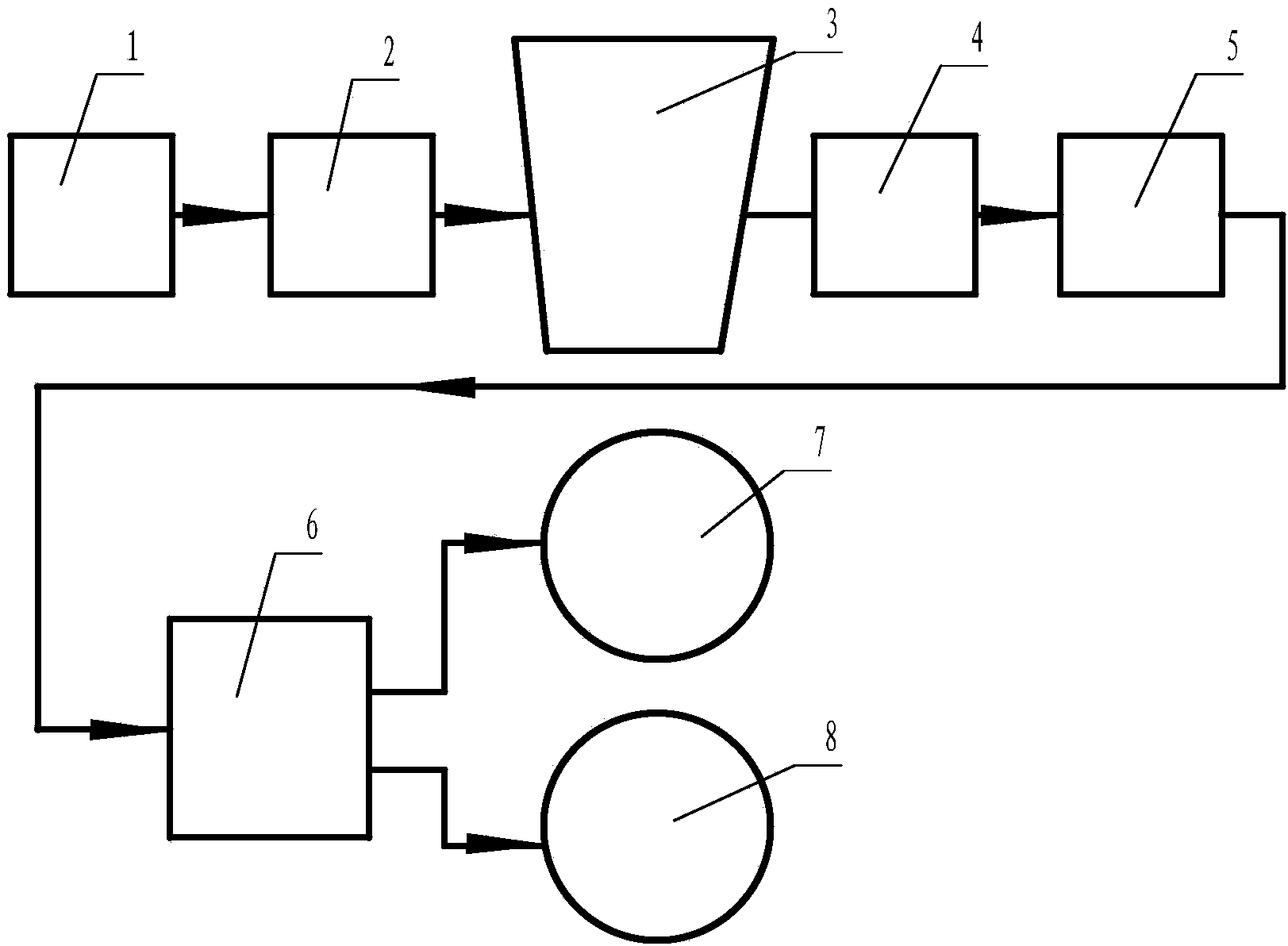

[0014] Example 1, such as figure 1 A crushing and adding system for prebaked anode raw and cooked products is shown, which is characterized by: 500T hydraulic crusher 1, large-inclination belt conveyor 2, double-knock multifunctional crusher 3, belt conveyor 4, bucket elevator 5. The distributing valves 6 are installed sequentially, and the distributing valves communicate with the cooked crushing bin 7 and the raw material bin 8 respectively through pipelines. A grate plate with an aperture of 20 × 35mm is housed in the described hammering type multifunctional crusher. When using this crushing system, pre-baked anode raw and cooked products are pre-crushed by a 500T hydraulic crusher, and then enter the double-knock multifunctional crusher for fine crushing through a large-inclination belt conveyor, and then the belt conveyor enters the bucket elevator. The distributing valve enters the cooked crushing bin and the raw crushing bin respectively for production and use. Becaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com