A method for removing impurities and preparing chromium oxide in a potassium-based sub-molten salt solution

A sub-molten salt and chromium oxide technology is applied in the field of solution crystal liquid removal and chromium oxide preparation after the reaction of chromium salt production sub-molten salt. problems such as long aging time, to achieve the effect of easy filtration and washing, low chromium band loss, and coarse particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

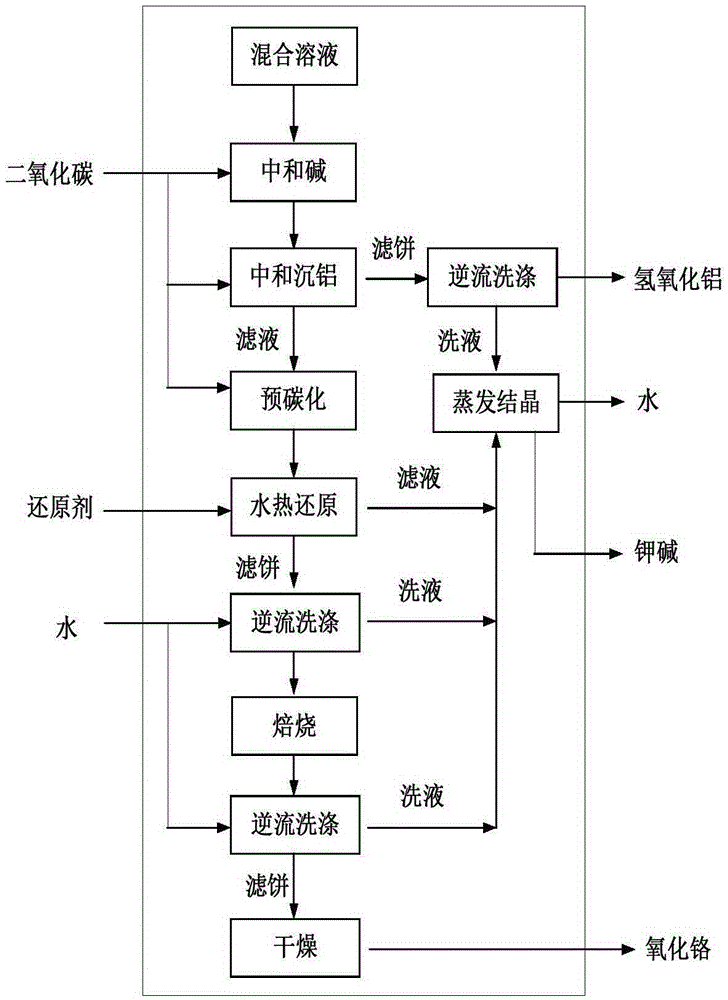

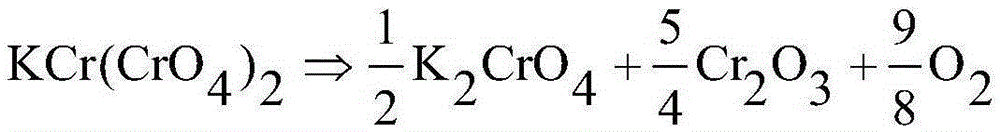

Method used

Image

Examples

Embodiment 1

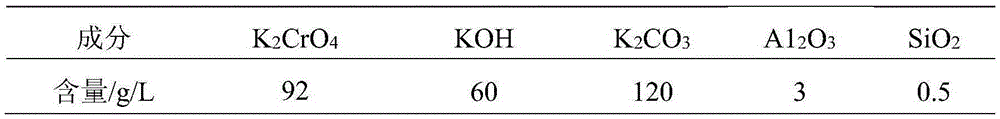

[0037] Choose potassium sub-molten salt solution from a chromium salt factory

[0038]

[0039] The alkaline solution obtained from the potassium-based sub-molten salt solution crystal solution is pumped into the storage tank, and the temperature is controlled to 60°C. Access to CO 2 (High purity CO 2 Mix with air, volume fraction 55%), neutralize potassium hydroxide for 0.4h; then add aluminum hydroxide seed crystals with a seed crystal coefficient of 0.5, neutralize and remove aluminum. The cumulative decomposition time is 2h. The removal rate of carbon and aluminum is 99.9%, and the removal rate of silicon is 98.5%. The aluminum hydroxide filter cake was washed countercurrently for 4 times, the temperature was 80°C, and the time was 30 minutes. After carbon content, the filter cake loses part of the water-soluble chromium, K in the filtrate 2 CO 3 Slightly reduced (90g / L), K 2 CO 3 :150g / L; KHCO 3 : 62g / L. The filtrate is pre-carbonized, the pressure is 0.8MPa, and the time...

Embodiment 2

[0041] Choose sodium chromate alkaline solution from a chromium salt factory

[0042]

[0043] The alkaline solution obtained from the potassium-based sub-molten salt solution crystal solution is pumped into the storage tank, and the temperature is controlled at 70°C. Access to CO 2 (High purity CO 2 Mix with air, volume fraction 36%), neutralize potassium hydroxide for 1.0h; then add aluminum hydroxide seed crystals with a seed crystal coefficient of 1.0, neutralize and remove aluminum. The cumulative decomposition time is 3h. The removal rate of carbon and aluminum is 99.5%, and the removal rate of silicon is 98.5%. The aluminum hydroxide filter cake was washed 4 times in countercurrent, at a temperature of 90°C, and a time of 15 minutes. After carbon content, the filter cake loses part of the water-soluble chromium, K in the filtrate 2 CO 3 Slightly reduced (190g / L), K 2 CO 3 :190g / L; KHCO 3 : 86g / L. The filtrate is pre-carbonized, the pressure is 0.6MPa, and the time is 1....

Embodiment 3

[0045] Choose sodium chromate alkaline solution from a chromium salt factory

[0046]

[0047] The alkaline solution obtained from the potassium-based sub-molten salt solution crystal solution is pumped into the storage tank, and the temperature is controlled to 60°C. Access to CO 2 (High purity CO 2 Mix with air, volume fraction 20%), neutralize potassium hydroxide for 0.5h; then add aluminum hydroxide seed crystals with a seed crystal coefficient of 0.6, neutralize and remove aluminum. The cumulative decomposition time is 2h. The removal rate of carbon and aluminum is 99.1%, and the removal rate of silicon is 98.0%. The aluminum hydroxide filter cake was washed countercurrently for 4 times, the temperature was 80°C, and the time was 20 minutes. After carbon content, the filter cake loses part of the water-soluble chromium, K in the filtrate 2 CO 3 Slightly reduced (280g / L), K 2 CO 3 :80g / L; KHCO 3 : 29g / L. The filtrate is pre-carbonized, the pressure is 0.4MPa, and the time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com