Isotropic graphite material and manufacturing method thereof

A graphite material and iso-directional technology, applied in the field of directional graphite materials and their manufacturing, can solve the problems of cracks, cracks, and long processing time on the surface of graphite materials, so as to shorten the processing time, improve crack defects, and improve isotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

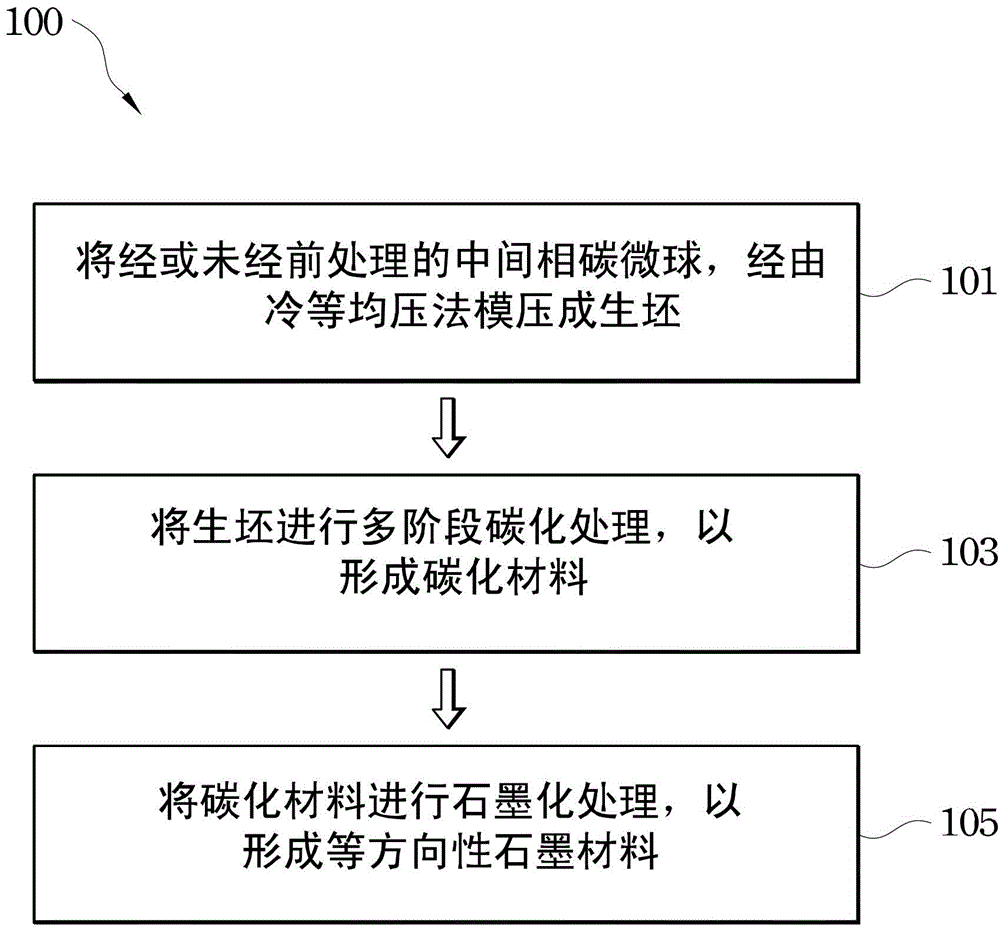

Method used

Image

Examples

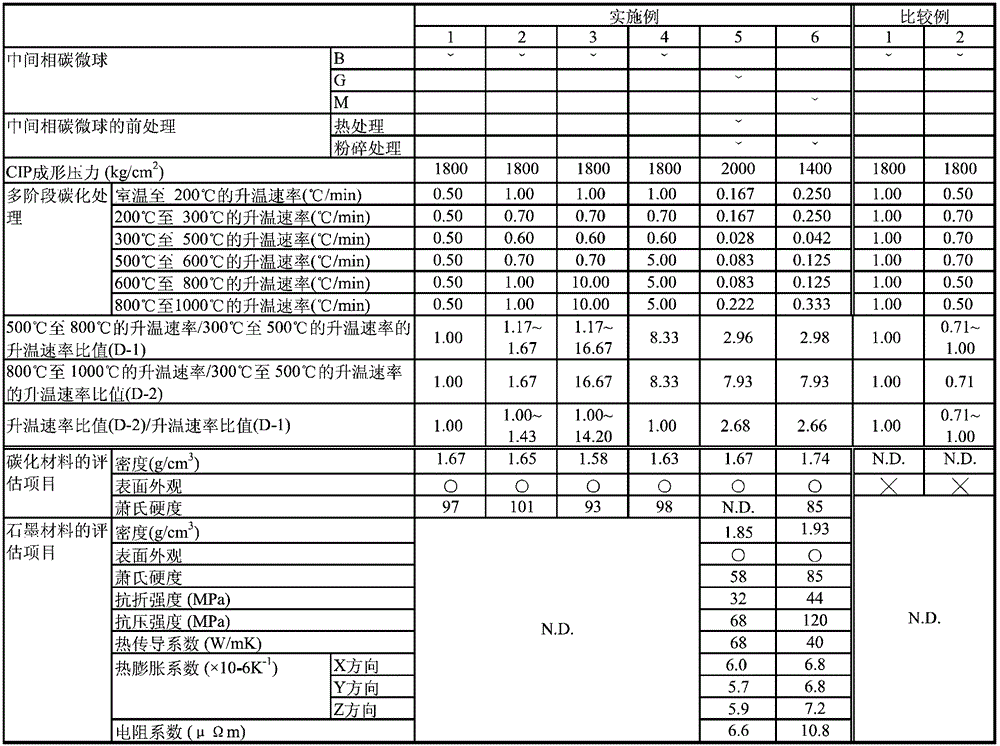

Embodiment 1 to Embodiment 4

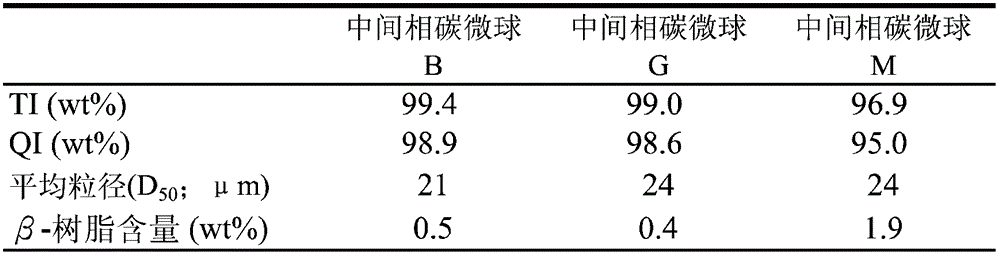

[0046] Embodiment 1 to embodiment 4 use mesocarbon microsphere B as raw material, wherein the basic information of mesocarbon microsphere B is listed in Table 1 (its TI is 99.4%, QI is 98.9%, average particle diameter (D 50 ) is 21 μm; Sinosteel Carbon Chemical Co., Ltd.).

[0047] About 55 grams of the above-mentioned mesocarbon microspheres B without pretreatment are filled in a cylindrical rubber mold (mold wall thickness 1.0 mm) with an inner diameter of about 25 mm, wherein the filling height of the mesocarbon microspheres in the mold is It is about 140mm. After compacting with a homogeneous rubber cover on the mold cover, carry out simple packaging (for example, use electrical tape to wrap it tightly) to avoid contamination caused by pressurized liquid intruding into the mold inadvertently during the cold equalization operation.

[0048] The above-mentioned mold containing mesophase carbon microspheres is placed in a cold isostatic pressure equipment (CL4.5-22-30, Nikki...

Embodiment 5

[0052] Embodiment 5 uses mesocarbon microsphere G as raw material, wherein the basic information of mesocarbon microsphere G is listed in Table 1 (its TI is 99.0%, QI is 98.6%, average particle diameter (D 50 ) is 24 μm; China Steel Carbon Chemical Co., Ltd.).

[0053] Under the protection of nitrogen gas, the mesophase carbon microspheres G were placed in the temperature range of 200° C. to 500° C. for 6 hours of heat treatment. Thereafter, it was pulverized using an air-induced pulverization equipment (ALG-2, Lingguang Industrial Co., Taiwan). After that, the particle size analyzer (Multisizer TM 3. Beckman Coulter, Inc., U.S.A.) analyzed the pulverized powder material of mesocarbon microspheres, the average particle size (D 50 ) is about 7 μm.

[0054] Next, about 860 grams of the above-mentioned pretreated powder were filled in a cylindrical rubber mold with an inner diameter of 100 mm (mold wall thickness 4.0 mm), and the filling height of the pulverized powder in the ...

Embodiment 6

[0060] Embodiment 6 uses mesophase carbon microspheres M as raw material, wherein the basic information of mesocarbon microspheres M is listed in Table 1 (its TI is 96.9%, QI is 95.0%, average particle diameter (D 50 ) is 24 μm; China Steel Carbon Chemical Co., Ltd.).

[0061] Mesocarbon microspheres M were pulverized using an air-induced pulverizing device (the same as that used in Example 5) before use; the particle size analyzer (same as that used in Example 5) was used to analyze the mesocarbon microspheres through Average particle size after pulverization (D 50 ) is about 5 μm.

[0062] Next, about 250 grams of the above-mentioned pretreated powder was filled in a cylindrical rubber mold with an inner diameter of 71 mm (mold wall thickness 1.0 mm), and the filling height of the pulverized powder in the mold was about 118 mm.

[0063] The above-mentioned mold filled with mesophase carbon microspheres pretreated by crushing is placed in a cold equal pressure equipment (CL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com