Full CNC spiral bevel gear milling machine

A technology of spiral bevel gears and gear milling machines, which is applied in gear tooth manufacturing devices, gear cutting machines, belts/chains/gears, etc., which can solve the loss of transmission accuracy and transmission efficiency, the speed limit of tool spindle movement, and the influence of bevel gear machining accuracy. and other problems, to achieve the effect of improving machining accuracy and smoothness, simplifying transmission structure, improving transmission accuracy and transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

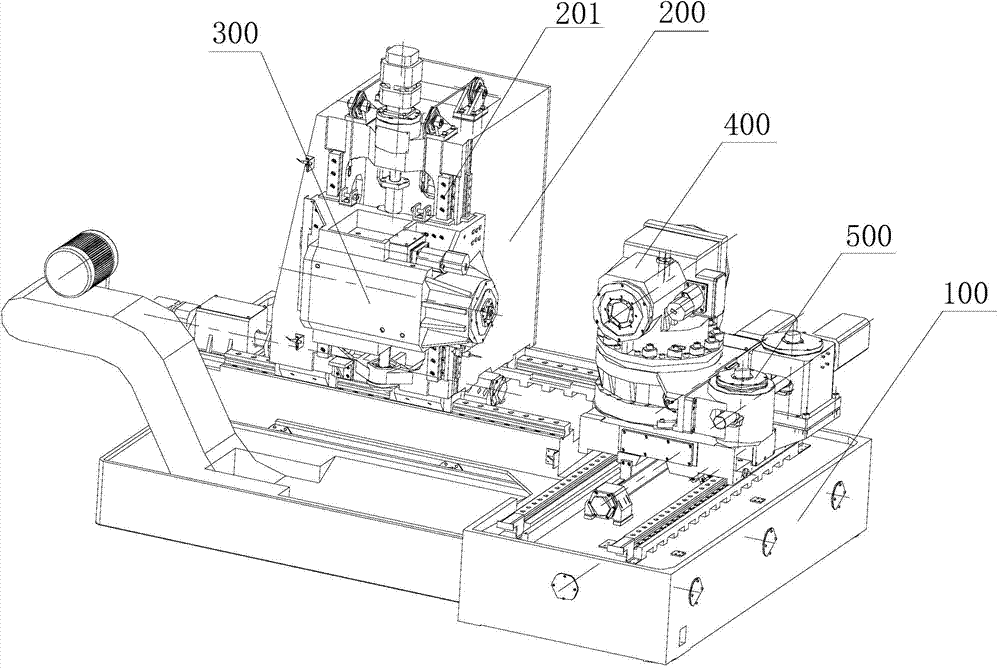

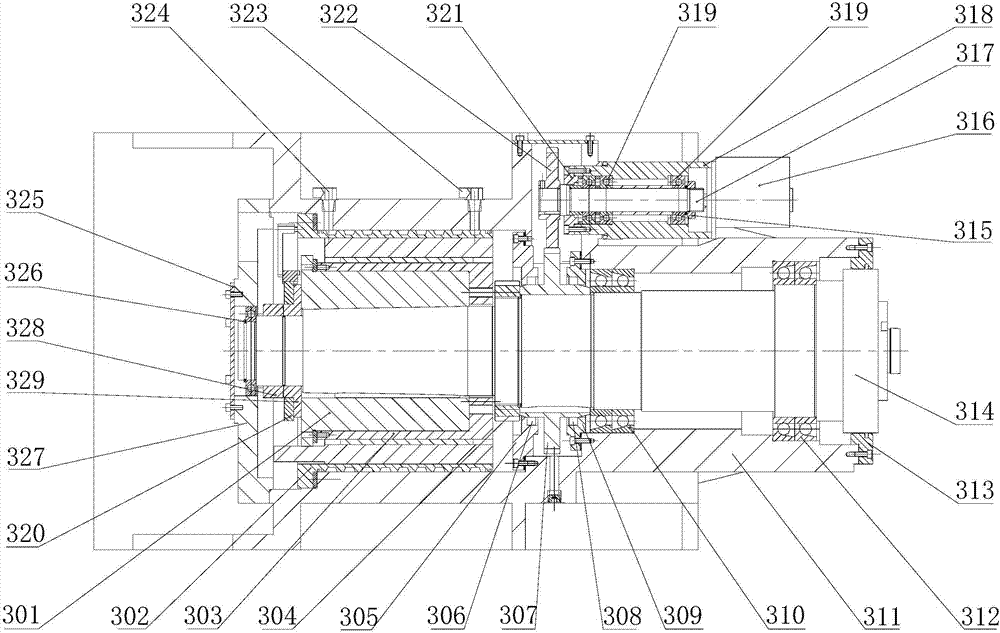

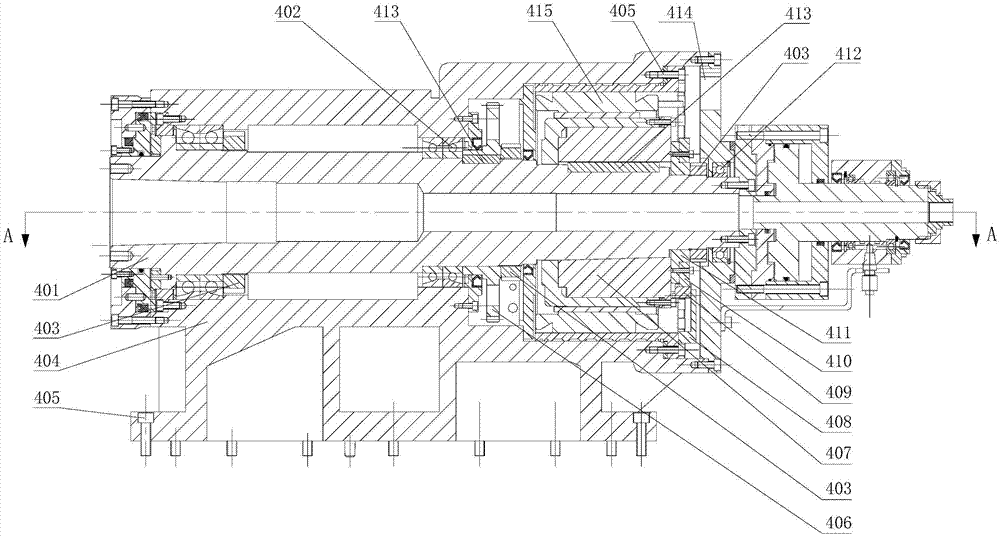

[0037] see Figure 1-Figure 9 , full CNC spiral bevel gear milling machine, including bed 100, column 200, tool box 300, workpiece box 400, turntable drive 500, electrical system, pneumatic system, hydraulic system and cooling system. Two pairs of horizontal and mutually perpendicular linear guide rails are arranged on the bed 100, a pair of linear guide rails 201 perpendicular to the bed guide rails and parallel to each other are fixed on the column, and the column and the turntable transmission device are respectively arranged on the bed on the linear guide. The tool box 300 is hung on the linear guide rail 201 on the outer side of the column, and the tool box includes a tool spindle box and a tool spindle arranged in the tool spindle box....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com