Thread shearing or presser foot lifting drive mechanism of sewing machine and thread shearing or presser foot lifting device

A technology of thread trimming mechanism and driving mechanism, which is applied in the field of sewing machines, can solve the problems that the electromagnet electromagnet stroke cannot be changed flexibly, affecting the stable operation of the sewing machine, large shaking and noise, etc., so as to reduce the risk of oil leakage, occupy a small space, reduce The effect of the driving source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

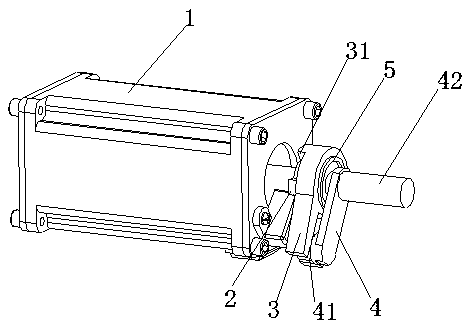

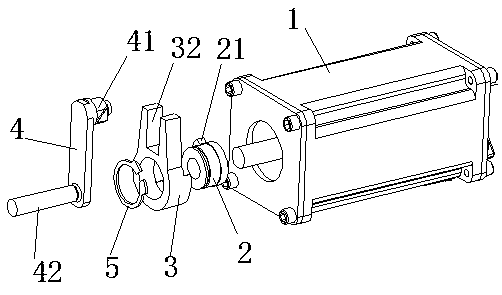

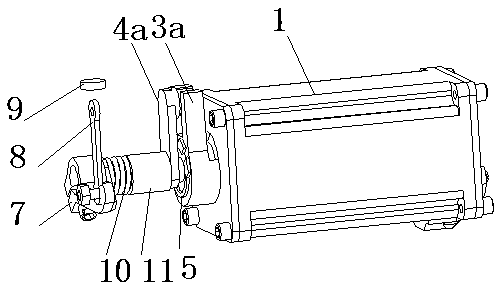

[0026] refer to Figure 1-7, the present invention is a specific embodiment for improving the cam or crank drive assembly driven by electromagnets and motors in the prior art: a thread trimming or presser foot driving mechanism of a sewing machine, including a motor 1, and the action of the motor 1 Controlled by the control box, it is used to drive the clutch drive assembly for thread trimming or presser foot lifting action. When it is used to dock the thread trimming mechanism and the motor shaft, it is set as the thread trimming clutch drive assembly, which is set as Embodiment 1; it is used for docking and lifting. The presser foot mechanism and the motor shaft are the presser foot lifter clutch drive assembly, which is set to embodiment 2; specifically, the thread trimmer or presser foot lifter clutch drive assembly includes a clutch mandrel 2, a clutch shift fork 3 and a drive crank 4, wherein The clutch mandrel 2 is arranged on the motor shaft of the motor 1, and a raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com