Method and device for integrally desulfurizing, denitrating and dust-removing by plasma

A plasma, desulfurization and denitration technology, applied in separation methods, chemical instruments and methods, electrostatic separation, etc., can solve the problems of corrosion, high cost, and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

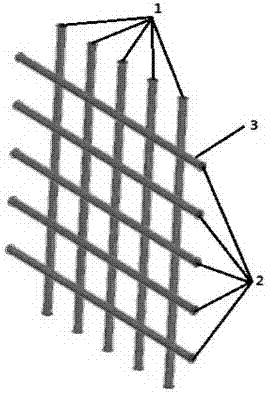

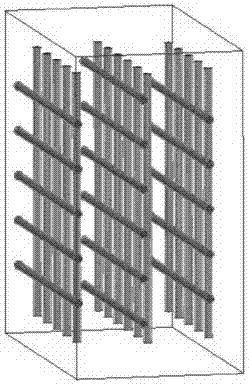

[0077] image 3 It is the flow chart of the first embodiment of the integration of plasma desulfurization, denitrification and dust removal in the present invention; Figure 4 It is the processing device diagram of the first embodiment of the integrated plasma desulfurization, denitrification and dust removal of the present invention; refer to the attached image 3 , 4 , a device for plasma integrated desulfurization, denitrification and dust removal according to the present invention is installed on the smoke pipe 5 and includes a cover body 6. The inlet 61 and the outlet 62 of the cover body 6 are respectively connected to the smoke pipe 5. Inside the cover body 6 Plasma flue gas treatment units 4 are arranged in parallel at intervals, and its structure refers to the attached figure 2 , the plasma flue gas treatment unit 4 includes a multi-layer plasma generation electrode (three layers are used in this embodiment), and the structure of the plasma generation electrode ref...

Embodiment 2

[0089] Figure 5 It is the flow chart of the second embodiment of the integrated plasma desulfurization, denitrification and dust removal of the present invention; Figure 6 It is a processing device diagram of the second embodiment of the integrated plasma desulfurization, denitrification and dust removal of the present invention.

[0090] The structure of this embodiment is a deformation made on the basis of Embodiment 1. The change is that the inlet 61 of the cover body 6 is provided with an ammonia pipeline inlet port, and the bottom of the cover body 6 is provided with a reclaimed material discharge port (refer to attached Figure 6 ), and the rest remain unchanged.

[0091] Attached below Figure 5 , attached Figure 6 Specifically introduce another embodiment of plasma integrated desulfurization, denitrification and dust removal processing method, including the following steps:

[0092] 1) After the flue gas is mixed with ammonia gas, it passes through the plasma g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com