Preparation method of purple perilla seed oil microcapsule

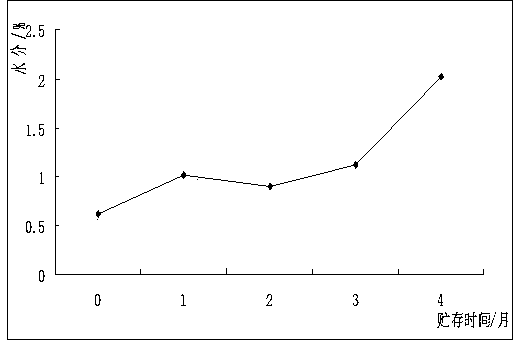

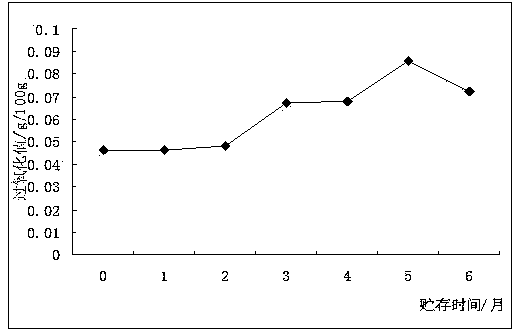

A technique for perilla seed oil and microcapsules, which is applied in the field of preparation of perilla seed oil microcapsules, can solve the problems of unsatisfactory shelf life, poor protein water solubility, low oil content and the like, and achieves good emulsion emulsification and embedding effect. Good, low peroxide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of a kind of perilla seed oil microcapsule, comprises the following steps:

[0038] (1) Ingredients. At room temperature, add maltodextrin, modified starch and sucrose in a weight ratio of 2:4:1 to the batching tank.

[0039] (2) Dissolving and sterilizing. At room temperature, add water twice the weight of the wall material to make an aqueous wall material solution with a solid content of 33.3% from the ingredients in step (1); sterilize for 30 min in a water bath at 80°C.

[0040] (3) Mixing and pre-emulsification of wall material and core material. After cooling the wall material aqueous solution obtained in step (2) to 50°C, add perilla seed oil at a ratio of 1:1 between the core material (perilla seed oil) and the wall material, and stir for 15 minutes to fully mix. Add water to form an emulsion with a solid content of 45%.

[0041] (4) High pressure homogenization. The emulsion obtained in step (3) was homogenized twice with a hi...

Embodiment 2

[0044] Embodiment 2: the preparation of a kind of perilla seed oil microcapsule, comprises the following steps:

[0045] (1) Ingredients. At room temperature, add maltodextrin, modified starch and sucrose in a weight ratio of 3:6:1 to the batching tank.

[0046] (2) Dissolving and sterilizing. At room temperature, add water twice the weight of the wall material to make an aqueous wall material solution with a solid content of 33.3% from the ingredients in step (1); sterilize in a water bath at 85°C for 30 min.

[0047] (3) Mixing and pre-emulsification of wall material and core material. After cooling the wall material aqueous solution obtained in step (2) to 50°C, add perilla seed oil at a ratio of 1:1.1 between the core material (perilla seed oil) and the wall material, and stir for 15 minutes to fully mix. Prepare an emulsion with a solid content of 50%.

[0048] (4) High pressure homogenization. The emulsion obtained in step (3) was homogenized twice with a high-press...

Embodiment 3

[0051] Embodiment 3: the preparation of a kind of perilla seed oil microcapsule, comprises the following steps:

[0052] (1) Ingredients. At room temperature, three wall materials, maltodextrin, modified starch and sucrose, were added in the batching tank with a weight ratio of 27:60:13.

[0053] (2) Dissolving and sterilizing. At room temperature, add water twice the weight of the wall material to prepare the ingredients in step (1) to make a wall material aqueous solution with a solid content of 33.3%; sterilize in a 90°C water bath for 20 min.

[0054] (3) Mixing and pre-emulsification of wall material and core material. After cooling the wall material aqueous solution obtained in step (2) to 50°C, add perilla seed oil at a ratio of 1:1.1 between the core material (perilla seed oil) and the wall material, and stir for 15 minutes to fully mix. Prepare an emulsion with a solid content of 50%.

[0055] (4) High pressure homogenization. The emulsion obtained in step (3) wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com