PFA spring

A technology of material and width, applied in the direction of springs, etc., can solve the problems of easy falling off of the coating, inability to use, and failure to find the spring in time, and achieve the effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

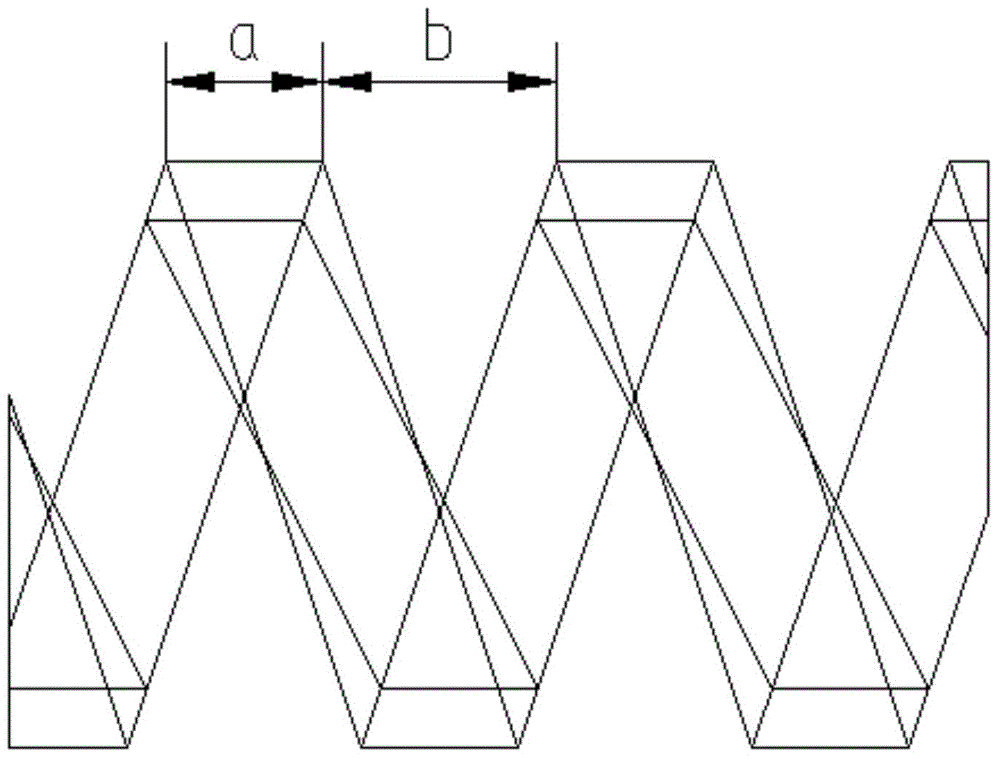

[0010] See figure 1 , PFA spring of the present invention adopts PFA material. The width a of the above-mentioned PFA spring is 3.5-4.5 mm, and the distance b is 5-7 mm.

[0011] Above-mentioned PFA spring manufacture method has following steps:

[0012] 1) Select the PFA tube with the required diameter and cut it to a suitable length;

[0013] 2) Fix the cut PFA tube on the tooling, and cut the tube into spiral strips with a blade;

[0014] 3) Wrap the spiral PFA strip on the shaping screw, put it into the oven, set the temperature at 250°C, and bake for 2 to 3 hours;

[0015] 4) Take out the spiral PFA strip from the oven, put it into pure water to cool, and obtain the PFA spring.

[0016] The shaping screw rod in the above step 3) is made of metal, and the distance between the grooves is the distance between the produced springs. That is, after the spiral cutting of the PFA tube is completed, the spiral PFA strip is screwed into the groove of the wire rod for positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com