Fish skin antifreeze protein as well as preparation method and application thereof

A technology of antifreeze protein and fish skin, which is applied in the field of fish skin antifreeze protein to achieve the effects of simple preparation method, improved structure and good antifreeze function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

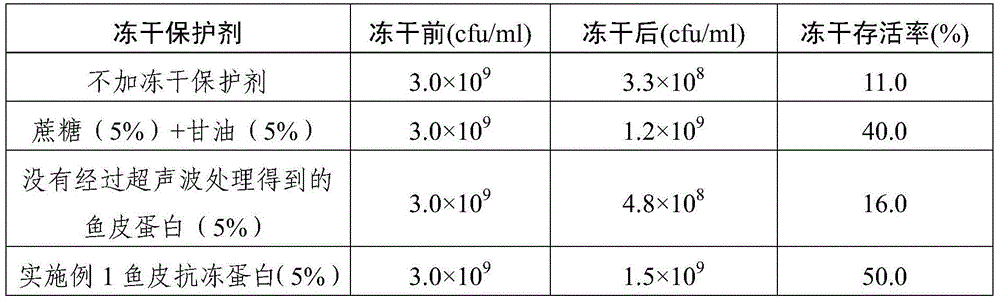

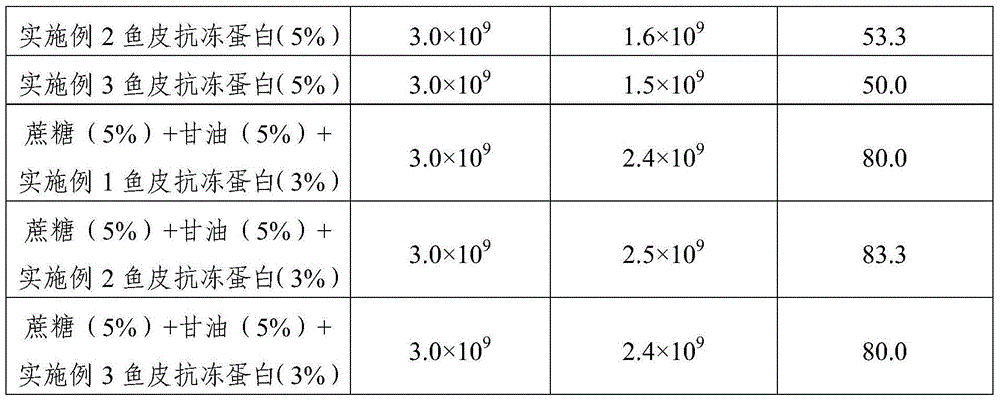

Embodiment 1

[0072] Embodiment 1: the preparation method of grass carp skin antifreeze protein

[0073] (1) Choose 100 grams of frozen grass carp skin, thaw it at 7°C for 12 hours, wash the fish skin with clean water that meets the sanitary standards for drinking water, and the temperature of the cleaning water is 10°C; The fish skin is beaten into a slurry; then 150 grams of water 1.5 times the weight of the fish skin slurry is added to the beaten fish skin slurry, and the fish skin slurry is ground into a fish skin slurry by a colloid mill, and the upper layer of fat is removed by centrifugation at 6000g for 8 minutes to obtain fat-free fish skin Serum 245 grams.

[0074] (2) The degreased fish skin slurry obtained in step (1) was placed in an ultrasonic generator, and subjected to ultrasonic treatment with a power of 800w and a frequency of 25KHz for 10 minutes to change the tissue structure of fish skin protein.

[0075] (3) Add 0.2 grams of composite protease to the degreased fish sk...

Embodiment 2

[0079] Embodiment 2: the preparation method of cod skin antifreeze protein

[0080] (1) Choose 200 grams of frozen cod skin, thaw it at 7°C for 10 hours, wash the fish skin with clean water that meets the drinking water hygiene standard, and the cleaning water temperature is 10°C; Beat the fish skin into a slurry; then add 200 grams of water 1.0 times the weight of the fish skin slurry to the beaten fish skin slurry, use a colloid mill to grind the fish skin slurry, and centrifuge at 5000g for 12 minutes to remove the upper layer of fat to obtain fat-free fish skin Serum 388 grams.

[0081] (2) The degreased fish skin slurry obtained in step (1) was placed in an ultrasonic generator, and subjected to ultrasonic treatment with a power of 900w and a frequency of 20KHz for 15 minutes to change the tissue structure of fish skin protein.

[0082] (3) According to the ratio of 0.3% by weight of fish skin weight, add 0.6 grams of composite protease to the degreased fish skin slurry ...

Embodiment 3

[0086] Embodiment 3: the preparation method of tilapia fish skin antifreeze protein

[0087] (1) Select 100 grams of frozen tilapia fish skin, thaw it at 7°C for 15 hours, wash the fish skin with clean water that meets the drinking water hygiene standard, and the cleaning water temperature is 10°C; after cleaning the fish skin, use a beating The machine beats the fish skin into a slurry; then add 300 grams of water 3.0 times the weight of the fish skin slurry to the beaten fish skin slurry, use a colloid mill to grind the fish skin slurry, and centrifuge at 4000g for 12 minutes to remove the upper layer of fat to obtain fat-free Fish skin slurry 390g.

[0088] (2) The degreased fish skin slurry obtained in step (1) was placed in an ultrasonic generator, and subjected to ultrasonic treatment with a power of 1000w and a frequency of 25KHz for 10 minutes to change the tissue structure of fish skin protein.

[0089] (3) According to the ratio of 0.5% by weight of the fish skin we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com