Method for preparing micron-order alumina fiber

A micron-sized alumina fiber technology, applied in the field of preparing micron-sized alumina fibers, can solve the problems of long production cycle, many influencing factors, and high price, and achieve the effects of short reaction time, low preparation cost, and low-cost equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

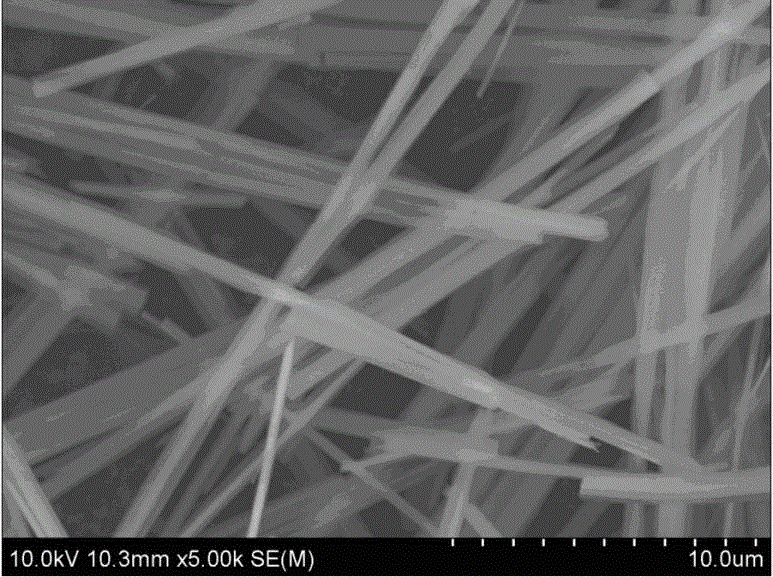

Image

Examples

Embodiment 1

[0021] a. Preparation of alumina fiber precursor

[0022] Weigh a certain mass of diethylenetriaminepentaacetic acid (DTPA), add deionized water, the ratio of diethylenetriaminepentaacetic acid to deionized water is 1:100, and heat in a water bath at 80°C to make diethylenetriaminepentaacetic acid (DTPA) The amine pentaacetic acid is completely dissolved, and a certain quality of aluminum nitrate is added, the ratio of aluminum nitrate to diethylenetriamine pentaacetic acid is 5:1, after the precipitation occurs, continue to stir for 2 hours, age for 4 hours, filter the precipitate under reduced pressure, Dry at a constant temperature of 80°C for 6 hours to obtain an alumina fiber precursor;

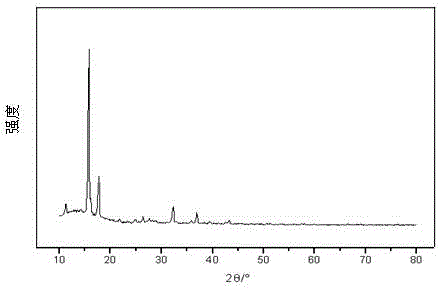

[0023] b. High temperature calcination of alumina fiber precursor

[0024] The obtained alumina fiber precursor was placed in a quartz crucible, heated at 1200° C. in an air atmosphere, and kept for 2 hours to obtain a white solid.

Embodiment 3

[0026] a. Preparation of alumina fiber precursor

[0027] Take a certain quality of diethylenetriaminepentaacetic acid (DTPA), add deionized water, the ratio of diethylenetriaminepentaacetic acid to deionized water is 1:100, and heat it in a water bath at 80°C to make diethylenetriamine Pentaacetic acid is completely dissolved, adding a certain quality of aluminum nitrate, the ratio of the amount of aluminum nitrate to diethylenetriaminepentaacetic acid is 5:1, after the precipitation, continue to stir for 2 hours, age for 4 hours, filter the precipitation under reduced pressure, 80 ℃ constant temperature drying for 6 hours to obtain the alumina fiber precursor;

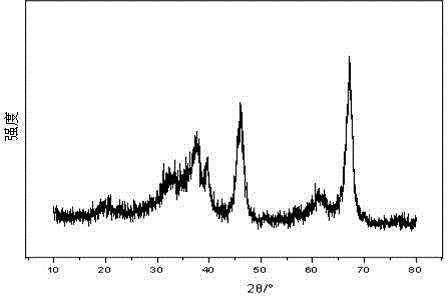

[0028] b. High temperature calcination of alumina fiber precursor

[0029] The obtained alumina fiber precursor was placed in a quartz crucible, heated at 1000° C. in an air atmosphere, and kept for 2 hours to obtain a white solid.

[0030] Example 3

[0031] a. Preparation of alumina fiber precursor

[0032] Wei...

Embodiment 4

[0036] a. Preparation of alumina fiber precursor

[0037] Weigh a certain mass of diethylenetriaminepentaacetic acid (DTPA), add deionized water, the ratio of diethylenetriaminepentaacetic acid to deionized water is 1:100, and heat in a water bath at 80°C to make diethylenetriaminepentaacetic acid (DTPA) The amine pentaacetic acid is completely dissolved, and a certain quality of aluminum nitrate is added, the ratio of aluminum nitrate to diethylenetriamine pentaacetic acid is 5:1, after the precipitation occurs, continue to stir for 2 hours, age for 4 hours, filter the precipitate under reduced pressure, Dry at a constant temperature of 80°C for 6 hours to obtain an alumina fiber precursor;

[0038] b. High temperature calcination of alumina fiber precursor

[0039] The obtained alumina fiber precursor was placed in a quartz crucible, heated at 600° C. in an air atmosphere, and kept for 2 hours to obtain a white solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com