Device, system and method for encapsulating IGBT module

A technology for module packaging and equipment, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the performance of IGBT modules, difficult to accurately control the ratio of base materials and catalysts, etc., to achieve consistent performance indicators, reliable quality, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

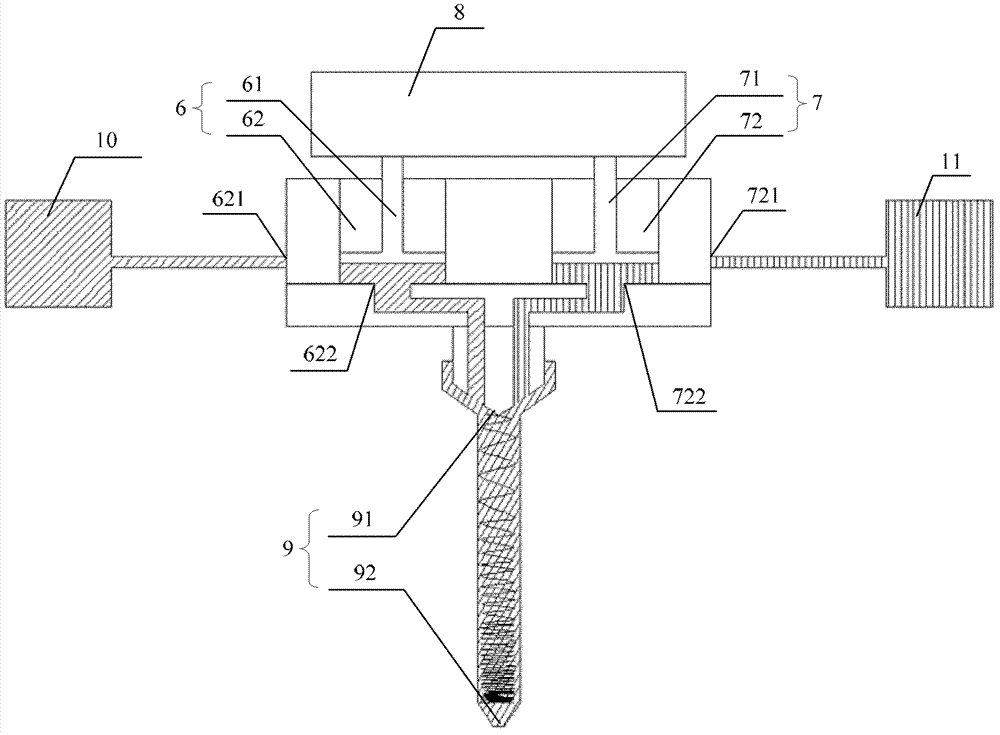

[0032] figure 2 It is a schematic structural diagram of the IGBT module packaging equipment provided by Embodiment 1 of the present invention.

[0033] see figure 2 , Embodiment 1 of the present invention provides an IGBT module packaging device, which includes a first piston 6, a second piston 7, a briquetting block 8 and a rubber mixing tube 9; the first piston 6 has a first piston rod 61 and a first cylinder 62 , the first cylinder 62 is provided with a first feed port 621 and a first discharge port 622, the first cylinder 62 is used to accommodate the base material; the second piston 7 has a second piston rod 71 and a second cylinder 72, the second cylinder 72 is provided with a second feed port 721 and a second discharge port 722, the second cylinder 72 is used to accommodate the catalyst; the briquetting block 8 and the first piston rod 61 and the second piston rod 71 fixed so that the first piston rod 61 and the second piston rod 71 rise or fall simultaneously under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com