Method for preparing micron-order alumina fiber

A technology of alumina fiber and micron level, which is applied in the field of preparation of micron level alumina fiber, can solve the problems of many influencing factors, long production cycle, high price, etc., and achieve the effect of low preparation cost, short reaction time, and low-cost equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

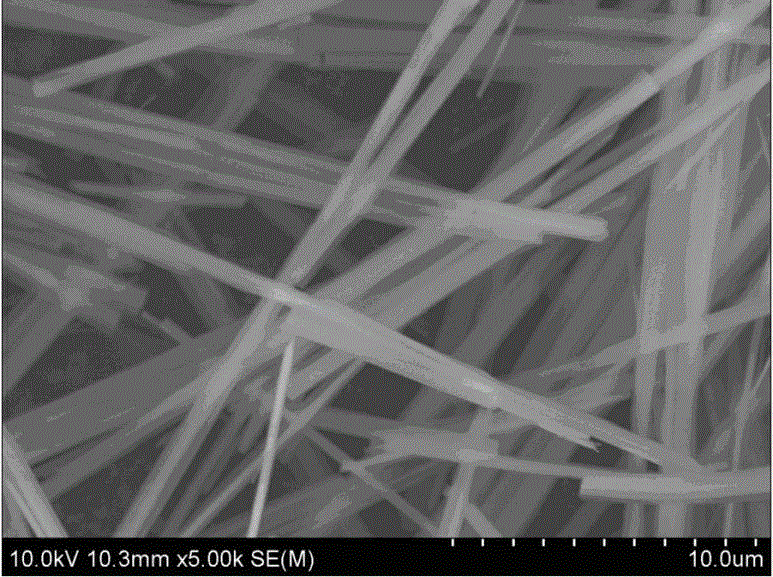

Image

Examples

Embodiment 1

[0021] a. Preparation of alumina fiber precursor

[0022] Weigh a certain mass of diethylenetriaminepentaacetic acid (DTPA), add deionized water, the ratio of diethylenetriaminepentaacetic acid to deionized water is 1:100, and heat in a water bath at 80°C to make diethylenetriaminepentaacetic acid (DTPA) The amine pentaacetic acid is completely dissolved, and a certain quality of aluminum nitrate is added, the ratio of aluminum nitrate to diethylenetriamine pentaacetic acid is 5:1, after the precipitation occurs, continue to stir for 2 hours, age for 4 hours, filter the precipitate under reduced pressure, Dry at a constant temperature of 80°C for 6 hours to obtain an alumina fiber precursor;

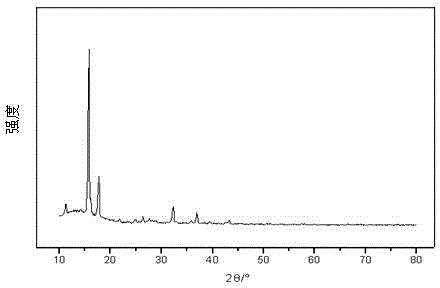

[0023] b. High temperature calcination of alumina fiber precursor

[0024] The obtained alumina fiber precursor was placed in a quartz crucible, heated at 1200° C. in an air atmosphere, and kept for 2 hours to obtain a white solid.

Embodiment 3

[0026] a. Preparation of alumina fiber precursor

[0027] Take a certain quality of diethylenetriaminepentaacetic acid (DTPA), add deionized water, the ratio of diethylenetriaminepentaacetic acid to deionized water is 1:100, and heat it in a water bath at 80°C to make diethylenetriamine Pentaacetic acid is completely dissolved, adding a certain quality of aluminum nitrate, the ratio of the amount of aluminum nitrate to diethylenetriaminepentaacetic acid is 5:1, after the precipitation, continue to stir for 2 hours, age for 4 hours, filter the precipitation under reduced pressure, 80 ℃ constant temperature drying for 6 hours to obtain the alumina fiber precursor;

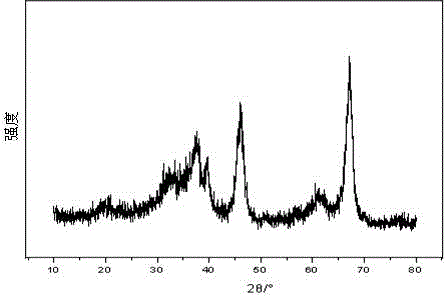

[0028] b. High temperature calcination of alumina fiber precursor

[0029] The obtained alumina fiber precursor was placed in a quartz crucible, heated at 1000° C. in an air atmosphere, and kept for 2 hours to obtain a white solid.

[0030] Example 3

[0031] a. Preparation of alumina fiber precursor

[0032] Wei...

Embodiment 4

[0036] a. Preparation of alumina fiber precursor

[0037] Weigh a certain mass of diethylenetriaminepentaacetic acid (DTPA), add deionized water, the ratio of diethylenetriaminepentaacetic acid to deionized water is 1:100, and heat in a water bath at 80°C to make diethylenetriaminepentaacetic acid (DTPA) The amine pentaacetic acid is completely dissolved, and a certain quality of aluminum nitrate is added, the ratio of aluminum nitrate to diethylenetriamine pentaacetic acid is 5:1, after the precipitation occurs, continue to stir for 2 hours, age for 4 hours, filter the precipitate under reduced pressure, Dry at a constant temperature of 80°C for 6 hours to obtain an alumina fiber precursor;

[0038] b. High temperature calcination of alumina fiber precursor

[0039] The obtained alumina fiber precursor was placed in a quartz crucible, heated at 600° C. in an air atmosphere, and kept for 2 hours to obtain a white solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com