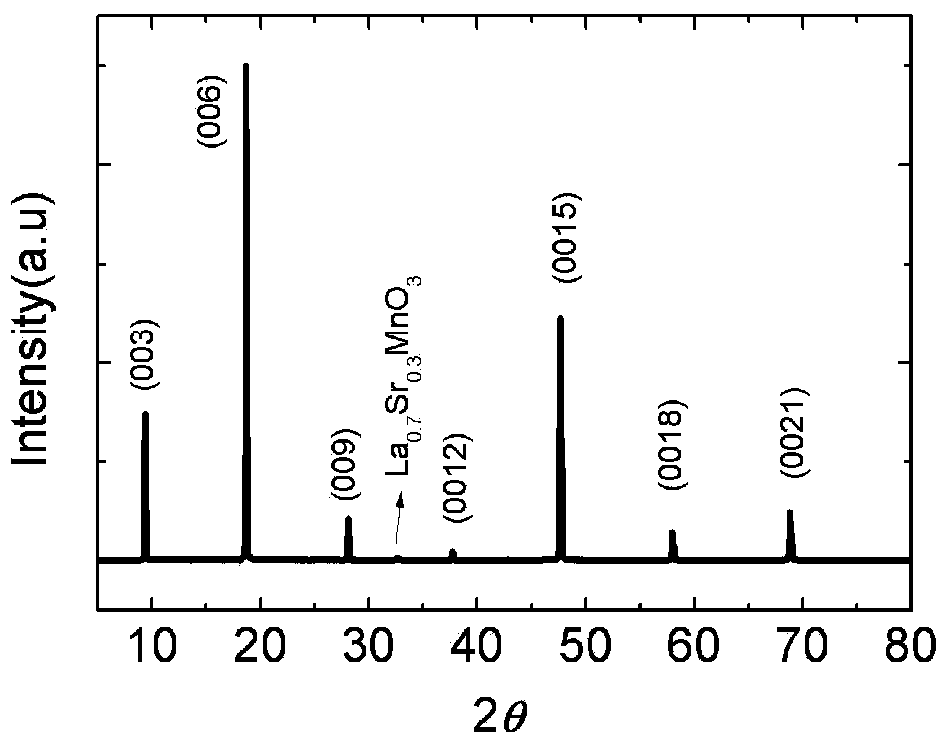

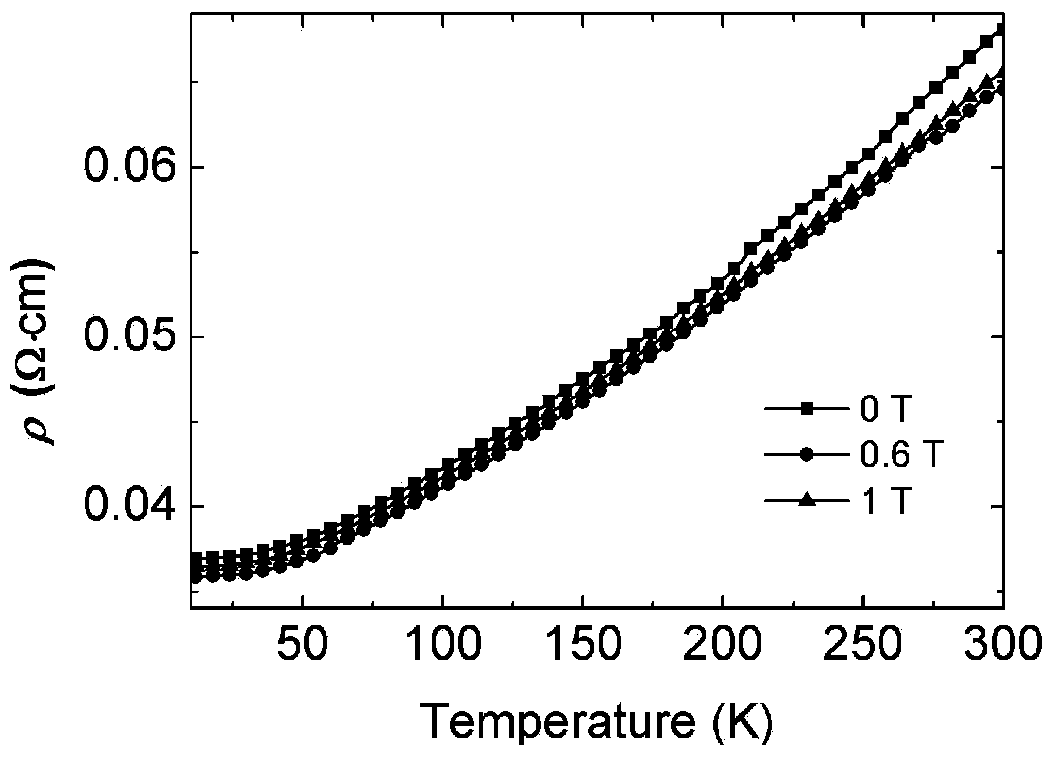

Method for preparing topological insulator Bi2Se3 and perovskite oxide La0.7Sr0.3MnO3 composite structure

A technology of perovskite oxides and topological insulators, applied in chemical instruments and methods, manganese oxide/manganese hydroxide, binary selenium/tellurium compounds, etc. The problem of high energy consumption and other problems can be achieved to reduce the preparation cost, low energy consumption, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

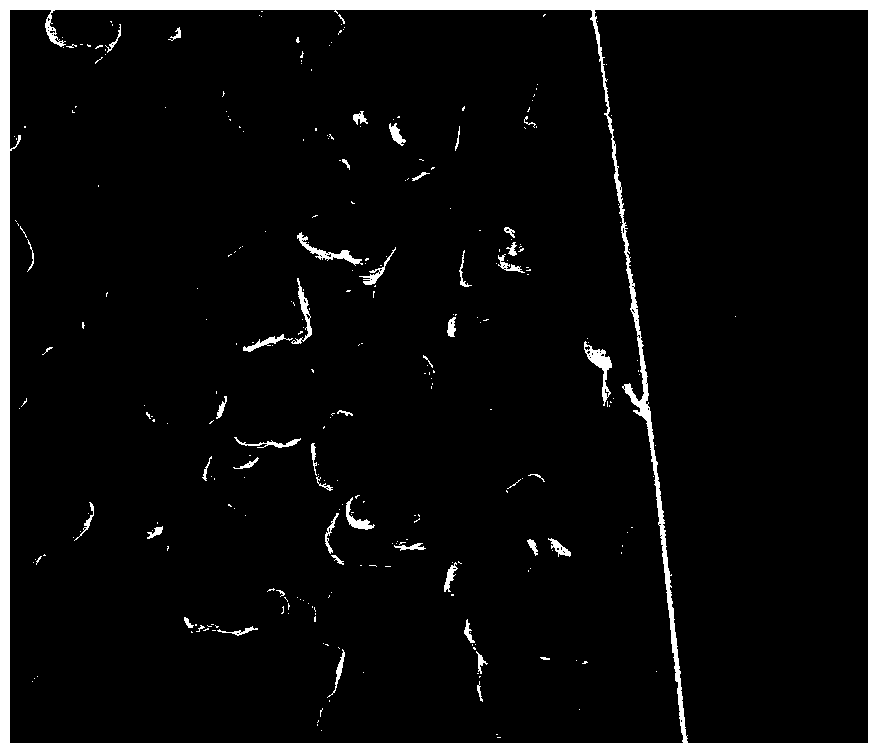

[0030] A kind of preparation topological insulator Bi 2 Se 3 With perovskite oxide La 0.7 Sr 0.3 MnO 3 The method of composite structure, its steps are:

[0031] a. Preparation of topological insulator single crystal: weigh high-purity bismuth powder and high-purity selenium powder at a molar ratio of 2:3 in an argon glove box, and grind and press them; then seal it with an air pressure of 0.9×10 -2 Pa vacuum quartz tube, then place the vacuum quartz tube in a tube furnace to slowly heat to 850 ℃ and keep it for 8 hours, and then evenly cool down to 620 ℃ in 24 hours, and then quench with cold water to obtain Bi 2 Se 3 Single chip

[0032] b. Preparation of perovskite oxide precursor powder: Dissolve lanthanum oxide, strontium carbonate, and manganese acetate into a nitric acid solution at a ratio of lanthanum, strontium, and manganese ions at a ratio of 7:3:10, and then add them after uniform mixing A complexing agent composed of citric acid and ethylene glycol with a molar ratio o...

Embodiment 2

[0038] A kind of preparation topological insulator Bi 2 Se 3 With perovskite oxide La 0.7 Sr 0.3 MnO 3 The method of composite structure, its steps are:

[0039] a. Preparation of topological insulator single crystal: weigh high-purity bismuth powder and high-purity selenium powder at a molar ratio of 2:3 in an argon glove box, grind and press them; then seal it with an air pressure of 0.5×10 -2 Pa vacuum quartz tube, then put the vacuum quartz tube in a tube furnace to slowly heat to 840 ℃ and keep it for 6 hours, and then take 20 hours to evenly cool down to 550 ℃, and then quench with cold water to obtain Bi 2 Se 3 Single chip

[0040] b. Preparation of perovskite oxide precursor powder: Dissolve lanthanum oxide, strontium carbonate, and manganese acetate into a nitric acid solution at a ratio of lanthanum, strontium, and manganese ions at a ratio of 7:3:10, and then add them after uniform mixing A complexing agent composed of citric acid and ethylene glycol with a molar ratio of...

Embodiment 3

[0046] A kind of preparation topological insulator Bi 2 Se 3 With perovskite oxide La 0.7 Sr 0.3 MnO 3 The method of composite structure, its steps are:

[0047] a. Preparation of topological insulator single crystal: weigh high-purity bismuth powder and high-purity selenium powder at a molar ratio of 2:3 in an argon glove box, grind and press them; then seal it with an air pressure of 0.2×10 -2 Pa in the vacuum quartz tube, then place the vacuum quartz tube in a tube furnace to slowly heat to 870℃ and keep it for 10h, then take 25 hours to evenly cool down to 650℃, and then quench with cold water to obtain Bi 2 Se 3 Single chip

[0048] b. Preparation of perovskite oxide precursor powder: Dissolve lanthanum oxide, strontium carbonate, and manganese acetate into a nitric acid solution at a ratio of lanthanum, strontium, and manganese ions at a ratio of 7:3:10, and then add them after uniform mixing A complexing agent composed of citric acid and ethylene glycol with a molar ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com