CaO guided technology for producing hydrogen through steam reforming and chemical looping combustion of methane

A methane and reforming reactor technology, applied in the fields of inorganic chemistry, chemical instruments and methods, hydrogen, etc., can solve the problem of not considering the content of adsorption strengthening and reforming, and achieve the effect of improving thermal energy efficiency

Inactive Publication Date: 2014-02-05

SOUTHWEST PETROLEUM UNIV

View PDF10 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Zhao Haibo and others published in the "Chinese Journal of Electrical Engineering" (Zhao Haibo, Chinese Journal of Electrical Engineering, 2012, Vol. 32, No. 11, pp. 87-94) simulated the chemical chain reforming hydrogen production system, but the system did not consider the content of adsorption-enhanced reforming

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

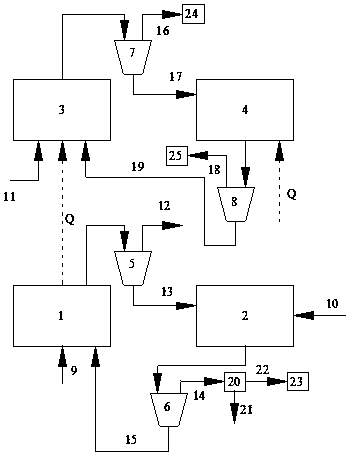

The invention discloses a CaO guided technology for producing hydrogen through steam reforming and chemical looping combustion of methane. The technology mainly comprises an air reactor, a fuel reactor, a reforming reactor and a calcinator. Methane and steam are taken as the raw materials for producing hydrogen, an oxygen carrier with NiO as the active component circulates continuously in the air reactor and the fuel reactor, the fuel methane can be completely oxidized by crystal oxygen provided by NiO, reducing-state Ni-based oxygen carrier is oxidized by air in the air reactor, a large quantity of heat released by oxidization is provided for the reforming reactor through wall heat transfer, CaO is added into the reforming reactor for absorbing CO2 generated in reaction, so as to enhance the reforming reaction to generate high-purity hydrogen, CaO adsorbs CO2 so as to form solid CaCO3 in the reforming reactor, and solid CaCO3 is pyrolyzed in the calcinator for CaO regeneration. Compared with the traditional methane steam reforming technology, the technology disclosed by the invention can be used for producing high-purity hydrogen at low temperature under normal pressure; the products at the outlet of the fuel reactor are only CO2 and H2O, so that high-purity CO2 can be obtained by condensing, the separation and collection technologies for CO2 are simplified, and the cost for producing hydrogen is sharply saved.

Description

Technical field: [0001] The invention relates to a CaO-guided methane steam reforming chemical looping combustion hydrogen production process, especially a hydrogen production process with CO 2 Efficient hydrogen production systems and methods for capture and collection. Background technique: [0002] With the increasingly prominent problems of energy crisis and environmental pollution, the development of clean and environmentally friendly new energy has attracted widespread attention. As a clean and efficient energy source, hydrogen is increasingly favored by people. At present, methane steam reforming is the most widely used industrial hydrogen production process. The related technologies of this process are very mature, but the process reaction conditions are harsh (above 800 ° C), and the production process is complicated. Although the reformed gas contains a large amount of hydrogen, further operations such as separation, compression and purification are still require...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B3/48

Inventor 诸林范峻铭李璐伶

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com