Catalyst for hydrogen production by methanol steam reforming and preparation method thereof

A technology of steam reforming and catalysts, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. It can solve the problems that the low-temperature catalytic performance of catalysts needs to be further improved. , to achieve the effect of promoting efficient oxidation-reduction process, improving hydrogen production efficiency, and easy ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

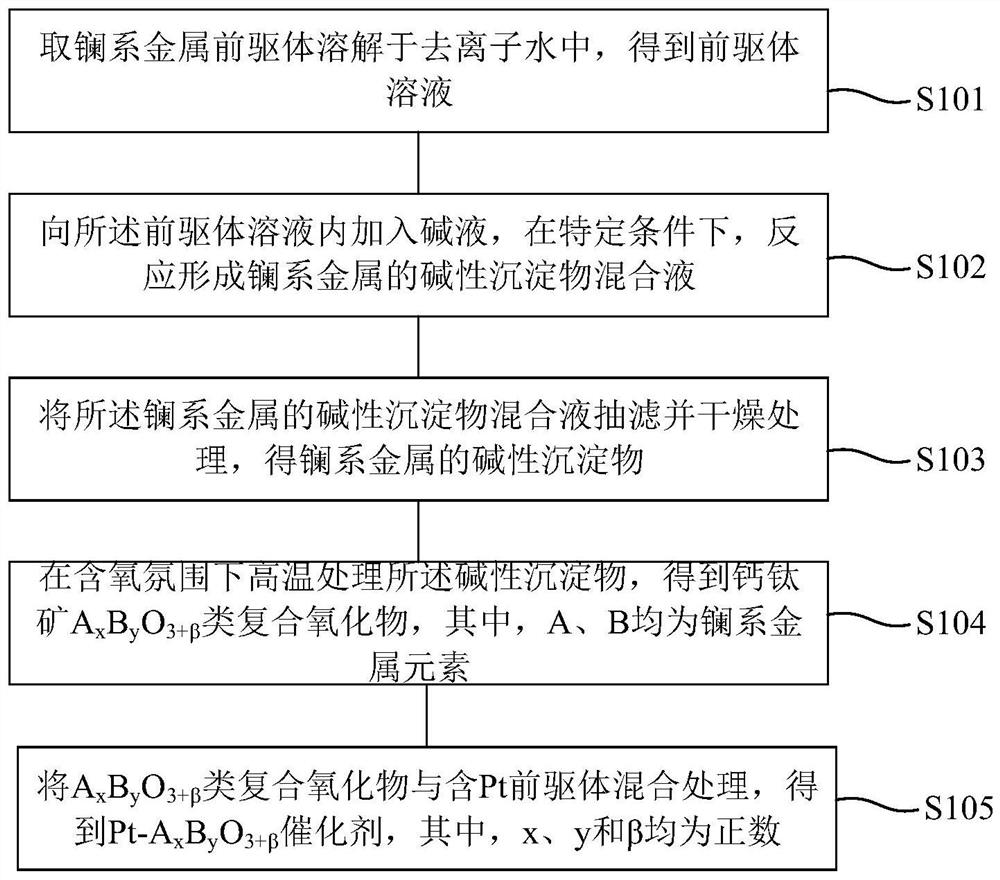

[0037] In this embodiment, the preparation method of described catalyst comprises the steps:

[0038] Step S101: dissolving the lanthanide metal precursor in deionized water to obtain a precursor solution.

[0039] The lanthanide metal precursors include but are not limited to La(C 2 h 3 o 2 ) 3 1.5H 2 O, Ce(C 2 h 3 o 2 ) 3 ·xH 2 O, Er(C 2 h 3 o 2 ) 3 4H 2 O, Eu(C 2 h 3 o 2 ) 3 , CeCl 2 , ErCl 3 at least one of the Ultrasonic stirring can be used in the dissolution process to fully disperse the lanthanide metal precursor.

[0040] Step S102: Add alkali solution to the precursor solution, and react under specific conditions to form a mixed solution of alkaline precipitates of lanthanide metals.

[0041] Specifically, under the condition of heating in a water bath, lye is added to the precursor solution, so that a reaction occurs in the solution. Preferably, the temperature of the water bath is 60°C-95°C, more preferably, it can be 70°C-90°C, and the stirr...

Embodiment 1

[0072] The concrete steps of catalyst preparation are as follows:

[0073] 1) Take 0.53g La(C 2 h 3 o 2 ) 3 1.5H 2 O, 0.92g Ce(C 2 h 3 o 2 ) 3 ·H 2 O was dissolved in deionized water, and ultrasonically stirred to fully disperse it;

[0074] 2) Heating in a water bath at 90°C, adding 0.5M NH 4 HCO 3 solution, adjust the pH to be about 8 to form an alkaline precipitate mixture of lanthanide metals;

[0075] 3) suction-filtering the above-mentioned alkaline precipitate mixture of lanthanide metals, and drying at 70° C. for 10 hours to obtain alkaline precipitate powder of lanthanide metals;

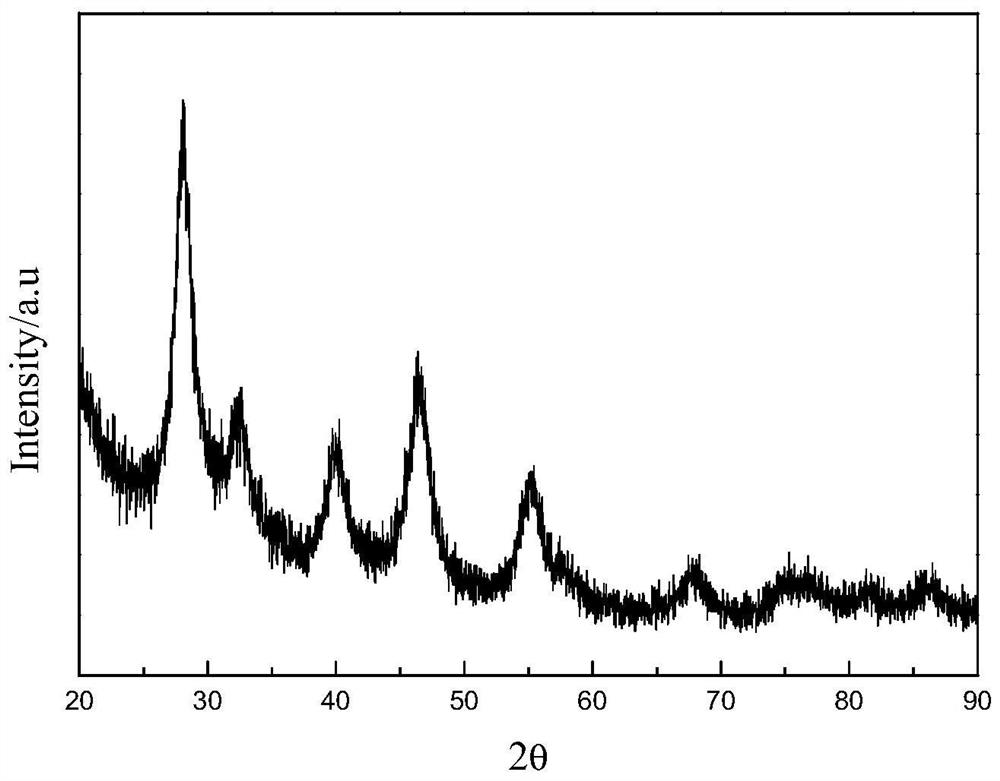

[0076] 4) High temperature treatment at 300°C in an air atmosphere, and heat preservation for 4 hours to obtain a light yellow lanthanide metal oxide powder, which is La 2 CeO 5 composite oxides;

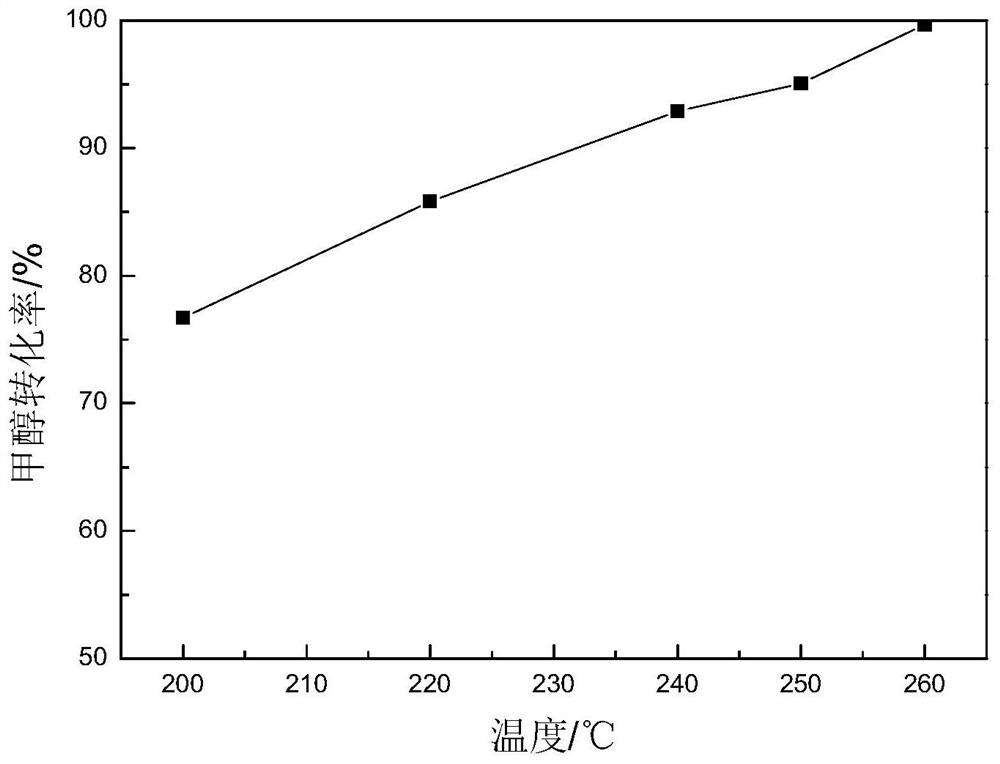

[0077] 5) the prepared La 2 CeO 5 Composite oxide and tetraamine platinum nitrate are thoroughly mixed to obtain a mixture, in which Pt accounts for La 2 CeO 5 10% of mass;

...

Embodiment 2

[0080] The concrete steps of catalyst preparation are as follows:

[0081] 1) Take 0.53g La(C 2 h 3 o 2 ) 3 1.5H 2 O, 0.92g Ce(C 2 h 3 o 2 ) 3 ·H 2 O was dissolved in deionized water, and ultrasonically stirred to fully disperse it;

[0082] 2) Heating in a water bath at 90°C, adding 0.5M NH 4 HCO 3 solution, adjust the pH to be about 8 to form an alkaline precipitate mixture of lanthanide metals;

[0083] 3) suction-filtering the above-mentioned alkaline precipitate mixture of lanthanide metals, and drying at 70° C. for 10 hours to obtain alkaline precipitate powder of lanthanide metals;

[0084] 4) High temperature treatment at 300°C in an air atmosphere, and heat preservation for 4 hours to obtain a light yellow lanthanide metal oxide powder, which is La 2 CeO 5 composite oxides;

[0085] 5) the prepared La 2 CeO 5 Composite oxide and tetraamine platinum nitrate are thoroughly mixed to obtain a mixture, in which Pt accounts for La 2 CeO 5 5% of mass;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com